Woodworker's Journal 1994-18-3, страница 12

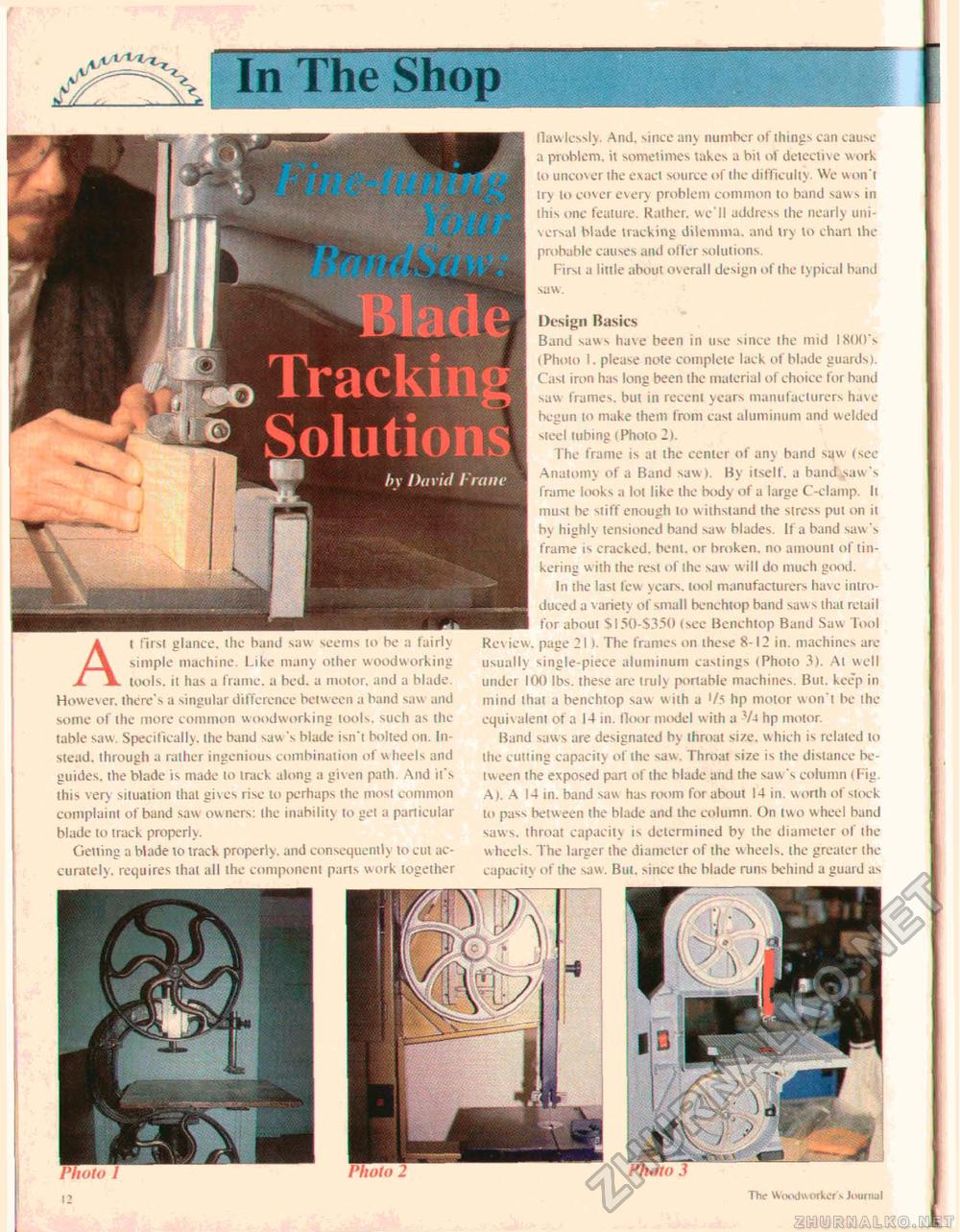

23 The Woodw orker's Journal At first glance, the hand saw seems 10 he a fairly simple machine. Like many other woodworking tools, it has a frame, a bed. a motor, and a blade. However, there's a singular difference between a band saw and some of the more common woodworking tools, such as the table saw. Specifically, the band saw's blade isn't bolted on. Instead. through a rather ingenious combination of w heels arid guides, the blade is made to track along a given path. And it's this very situation that gives rise to perhaps the most common complaint of band saw owners: the inability to get a particular blade to track properly. Getting a Wade to track properly, and consequently to cut accurately. requires that all the component parts work together flawlessly. And. since any number of things can cause a problem, it sometimes takes a bit of detective w ork to uncover the exact source of the difficulty We won't try lo cover every problem common to band saw s in this one feature. Rather, we'll address the nearly universal blade tracking dilemma, and try to chart the prohable causes and offer solutions. First a little about overall design of the typical band saw. Design Basics Band saws have been in use since the mid 1800's (Photo 1. please note complete lack of blade guardsi. Cast iron has long been ihe material of choice for band saw frames, but tn recent years manufacturers have begun to make them from east aluminum and welded steel tubing (Photo 2). The frame is al the center of any band saw (see Anatomy of a Band saw i. By itself, a band-saw's frame looks a lot like the body of a large C-clamp. It must be stiff enough to withstand the stress put on it by highly tensioned band saw blades. If a band saw s frame is cracked, bent, or broken, no amount of tinkering with the rest of the saw w ill do much good. In the last lew years, tool manufacturers have introduced a v ariety of small benchtop band saw s that retail for about SI50-S350 (see Benchtop Band Saw Tool Review, page 21 I. The frames on ihcse 8-12 in. machines are usually single-piece aluminum castings (Photo 3). At well under KM) lbs. these are trulv portable machines. But. keep in mind that a benchtop saw with a l/.s hp motor won't be the equivalent of a 14 in. floor m«xlel with a V*l hp motor. Band saws are designated by throat size, which is related lo the cutting capacity of the saw. Throat size is the distance between ihe exposed pan of the blade and the saw s column (Fig. A). A 14 in. band saw has room for about 14 in. worth of stock to pass between the blade and the column. On two wheel hand saws, throat capacity is determined by the diameter of the wheels. The larger the diameter of the wheels, ihe greater the capacity of the saw. But. since the blade runs behind a guard as |