Woodworker's Journal 1994-18-3, страница 10

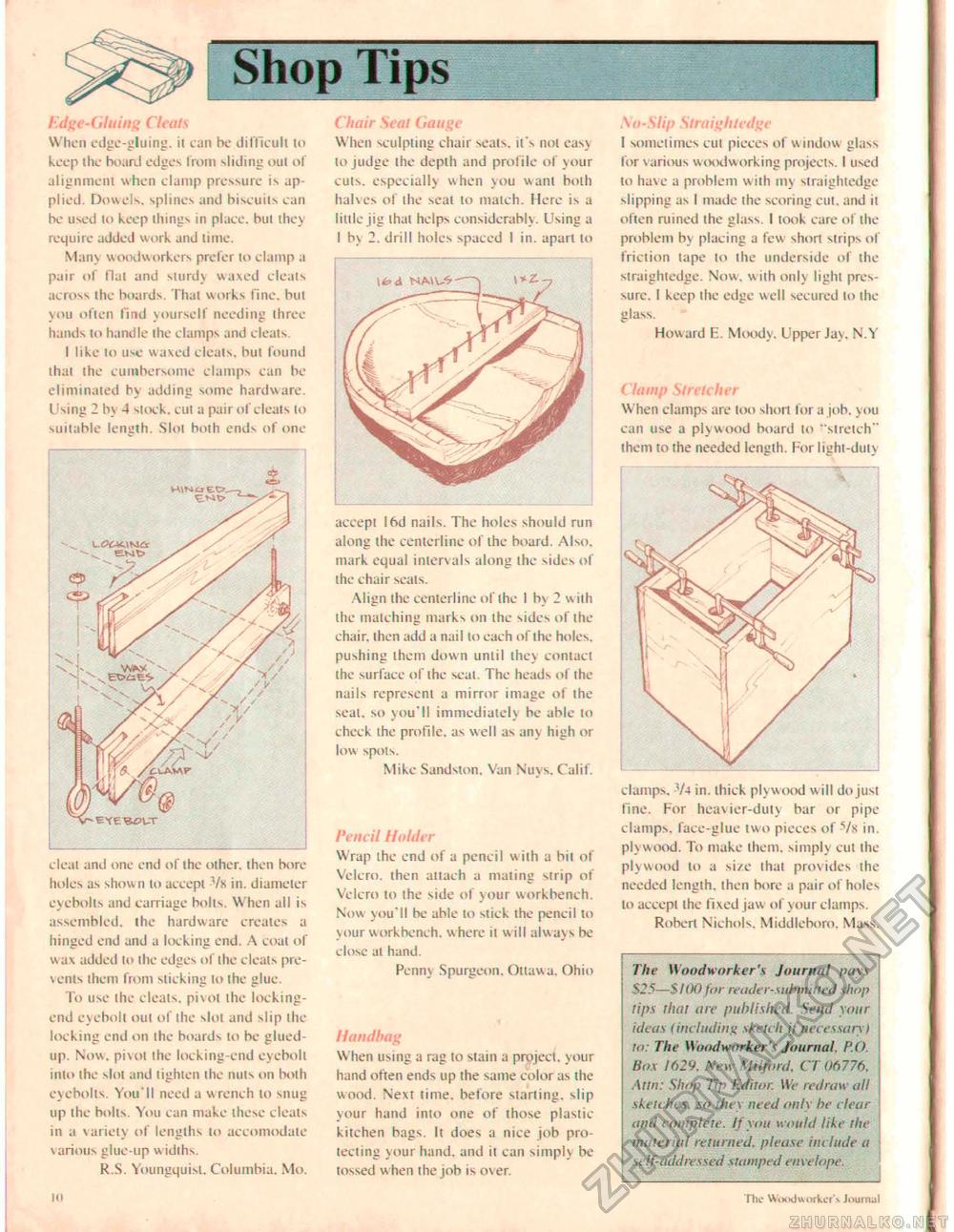

Shop Tips Edge-Gluing Cleats When edge-gluing, it can he difficult to keep the board edges from sliding out of alignment when clamp pressure is applied. Dowels, splines and biscuits can he used to keep things in place, hut they require added work and lime. Many woodworkers prefer to clamp a pair of Hat and sturdy waxed cleats across the boards. That works fine, hut you often find yourself needing three hands lo handle the clamps and cleats. I like lo use waxed cleats, hut found that the cumbersome clamps ean be eliminated hy adding some hardware. Using 2 by 4 stock, cut a pair of cleats to suitable length. Slot both ends of one cleat and one end of the other, then bore holes as shown lo accept -Vk in. diameter eycbolts and carriage bolts. When all is assembled, the hardware creates a hinged end and a locking end. A coal of wax added to the edges of the deals prevents ihcnt from sticking to the glue. To use the cleats, pivot ihe locking-end cyeboll out of the slot and slip the locking end on the boards to be glued-up. Now. pivot the loeking-end cvebolt into the slot and tighten the nuts on both eycbolts. You'll need a wrench lo snug up the holts. You ean make these cleats in a variety of lengths to accomodate various glue-up widths. R.S. Youngquisl. Columbia. Mo. Chair Seat Gauge When sculpting chair seats, it's not easy to judge ihe depth and profile of y our cuts, especially when you warn both halves of the seat to match. Here is a little jig that helps considerably. Using a I bv 2. drill holes spaced I in. apart lo accept I6d nails. The holes should run along the centcrline of the board. Also, mark equal intervals along the sides of the chair seals. Align the centerline of the 1 by 2 w ilh ihe matching marks on the sides of ihe chair, then add a nail lo each of the holes, pushing them down until they contact the surface of the seat. The heads of the nails represent a mirror image of the seal, so you'll immediately he able to check the profile, as well as anv high or low spots. Mike Sandston. Van Nuvs. Calif. Pencil Holder Wrap the end of a pencil with a bit of Vcicro. then attach a mating strip of Velcro to the side of your w orkbench. Now you'll be able lo stick the peneil to your workbench, where il will always be close at hand. Pennv Spurgeon. Ottawa. Ohio Handbag When using a rag to stain a project, your hand often ends up the same color as the wood. Next time, before siarting. slip your hand into one of those plastic kitchen hags. It does a nice job protecting your hand, and it can simply be tossed when the job is over. No-Slip Straightedge I sometimes cut pieces of window glass lor various woodworking projects. I used to have a problem with my straightedge slipping as I made the scoring cut. and il often mined the glass. I took eare of the problem by placing a few short strips of friction tape lo Ihe underside of the straightedge. Now. w ith only light pressure. I keep the edge well secured lo the glass. Howard E. Moody. Upper Jay, N Y Clamp Stretcher When clamps are loo short for a job. you can use a plywood board to "stretch" them to the needed length. For light-duty clamps. -V4 in. thick plywood will do just fine. For heavier-duly bar or pipe clamps, face-glue two pieces of "7s in. plywood. To make them, simply cut the plywood to a size thai provides the needed length, then bore a pair of holes lo accept the fixed jaw of your clamps. Robert Nichols. Middleboro. Mass. The Woodworker's Journal pays $2f>—$1 (H) for reader- submitted shop tips that are published. Send your ideas (including sketch if necessary I to: The Woodworker's Journal, P.O. Box 1629. New Milford, CT 06776. Attn: Shop Tip Editor. Hi- redraw all sketches, so they need only be clear and complete. If you would like the material returned, please include a self-addressed stamped envelope. in The Woodworker's Jouriut |