Woodworker's Journal 1994-18-5, страница 31

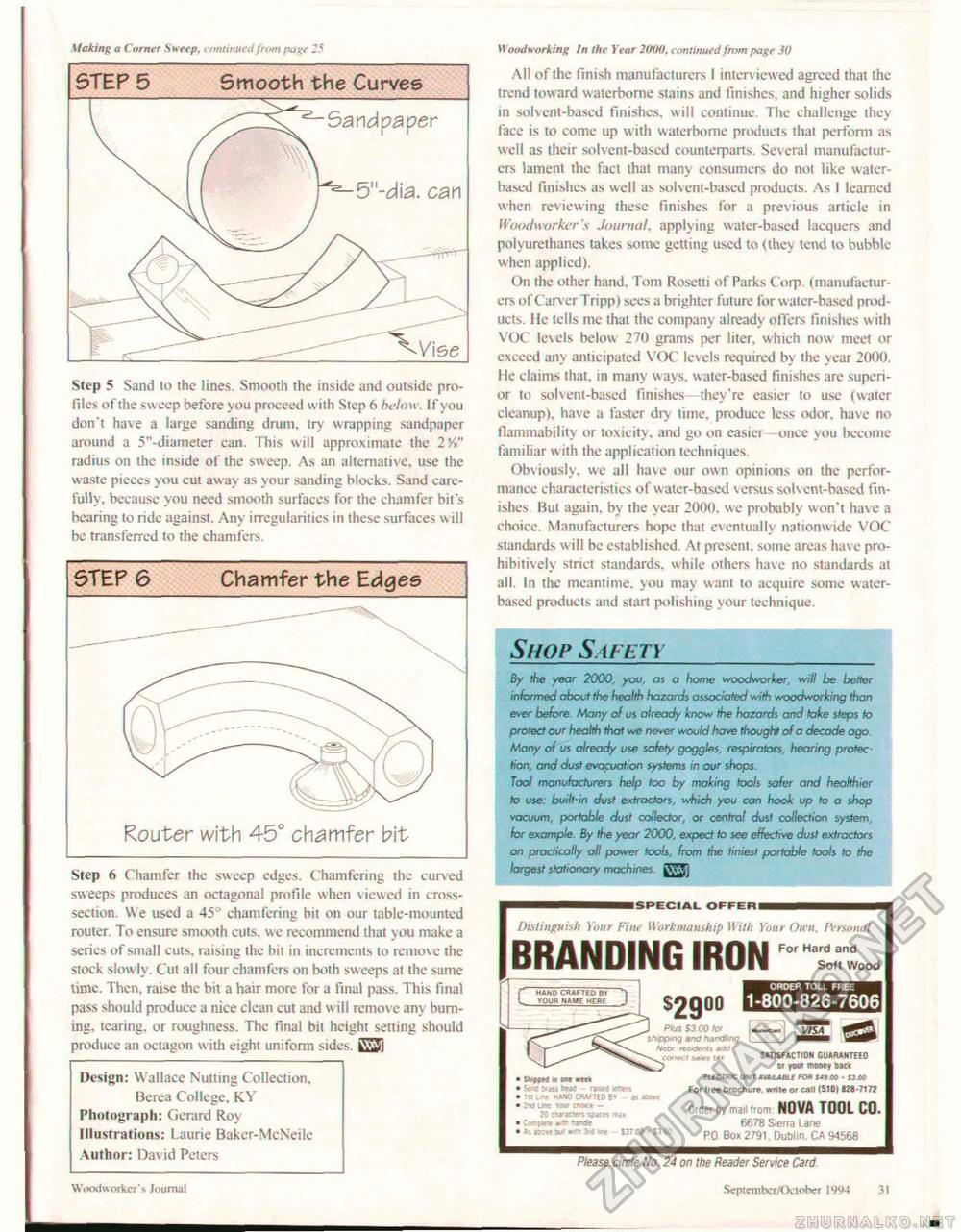

Making a Corner Sweep, continued from pane 25 STEP 5 Smooth the Curves Sandpaper -5"-dia, can Vise Step 5 Sand lo the lines. Smooth the inside and outside profiles of the sweep before you proceed with Step 6 below. If you don't have a large sanding drum, try wrapping sandpaper around a 5"-diameter can. This will approximate the 254" radius on the inside of the sweep. As an alternative, use the waste pieces you cut away as your sanding blocks. Sand carefully, because you need smooth surfaces for the chamfer bit's bearing to ride against. Any irregularities in these surfaces will be transferred to the chamfers. STEP 6 Chamfer the Edges Router with 45° chamfer bit Step 6 Chamfer the sweep edges. Chamfering the curved sweeps produces an octagonal profile when viewed in cross-section. We used a 45® chamfering bit on our table-mounted router. To ensure smooth cuts, we recommend that you make a series of small cuts, raising the bit in increments to remove the stock slowly. Cut all tour chamfers on both sweeps at the same lime. Then, raise the bit a hair more for a final pass. This final pass should produce a nice clean cut and w ill remove any burning. tearing, or roughness. The final bit height setting should produce an octagon with eight uniform sides. kV'Jl l>esign: Wallace Nutting Collection. Berea College. KY Photograph: Gerard Roy Illustrations: Laurie Bakcr-McNeilc Author: David Peters Woodworking In the Year 2000. continued fmm page 30 All of the finish manufacturers I interviewed agreed that the trend toward waterborne stains and finishes, and higher solids in solvent-based finishes, will continue. The challenge they face is to comc up with waterborne products that perform as well as their solvent-based counterparts. Several manufacturers lament the fact that many consumers do not like water-based finishes as well as solvent-based products. As I learned when reviewing these finishes for a previous article in Woodworker's Journal, applying water-based lacquers and polyurethanes takes some getting used to (they tend to bubble when applied). On the other hand. Tom Rosetti of Parks Corp. (manufacturers of Carver Tripp) sees a brighter future for water-based products. lie tells me that the company already offers finishes with VOC levels below 270 grams per liter, which now meet or exceed any anticipated VOC levels required by the year 2000. He claims that, in many ways, water-based finishes are superior to solvent-based finishes—they're easier to use (water cleanup), have a faster dry time, produce less odor, have no llammabiliiy or toxicity, and go on easier—once you become familiar w ith the application techniques. Obviously, wc all have our own opinions on the performance characteristics of water-based v ersus solvent-based finishes. But again, by the year 2000, we probably won't have a choice. Manufacturers hope that eventually nationwide VOC standards will be established. At present, some areas have prohibitively strict standards, while others have no standards at all. In the meantime, you may want to acquire some water-based products and start polishing your technique. Shop Safety_ By the year 2000, you, as a home woodworker, will be belter informed about the health hazards associated with woodworking than ever before. Many of us already know the hazards and lake steps to protect our health that we never would hove thought of a decode ago. Many of us already use safety goggles, respirators hearing protec lion, and dust evacuation systems in. our shops. Tool manufacturers help too by making fools safer and healthier to use: built-in dust extractors, which you can hook up to a shop vacuum, portable dust collector, or centra/ dust collection system, for example. By the year 2000, expect to see effective dust extractors ors practically all power tools, from the tiniest portoble tools to the largest stationery machines ^vil ■ SPECIAL OFFER! Distinguish Your Fine W orkmanship With Your Own, Personal BRANDING IRON t l $2Q00 • Sapped m one week • So ;: - fiK beatf v-.f - Teis • in L^C HJW0 CftAPTfD B* » MOST • 2no cnw F — 20 rtivaeterv spates nu« • .V ar-vf BJ- A i tr* £3? DC- - 1300 OROEfl TOLL FREE 1-800-826-7606 — w*, satisfaction guaranteed or your money b>ci CLIC'mC UMT AMUABLl FOR H)«. J3.0C For tree brochure, write or call (510\ 828-717? Order Oymailtron NOVA TOOL CO. 6678 Sierra l ane R0 Bo* 2791, Dublin. CA 94568 Pius $3 00 to shipping and handling Hety re&denti *OC cotrscl safe? r«x Please circle No. 24 on the Reader Service Card. Woodworker's Journal Septernbcr/Oeloher 1994 31 |