Woodworker's Journal 1994-18-5, страница 44

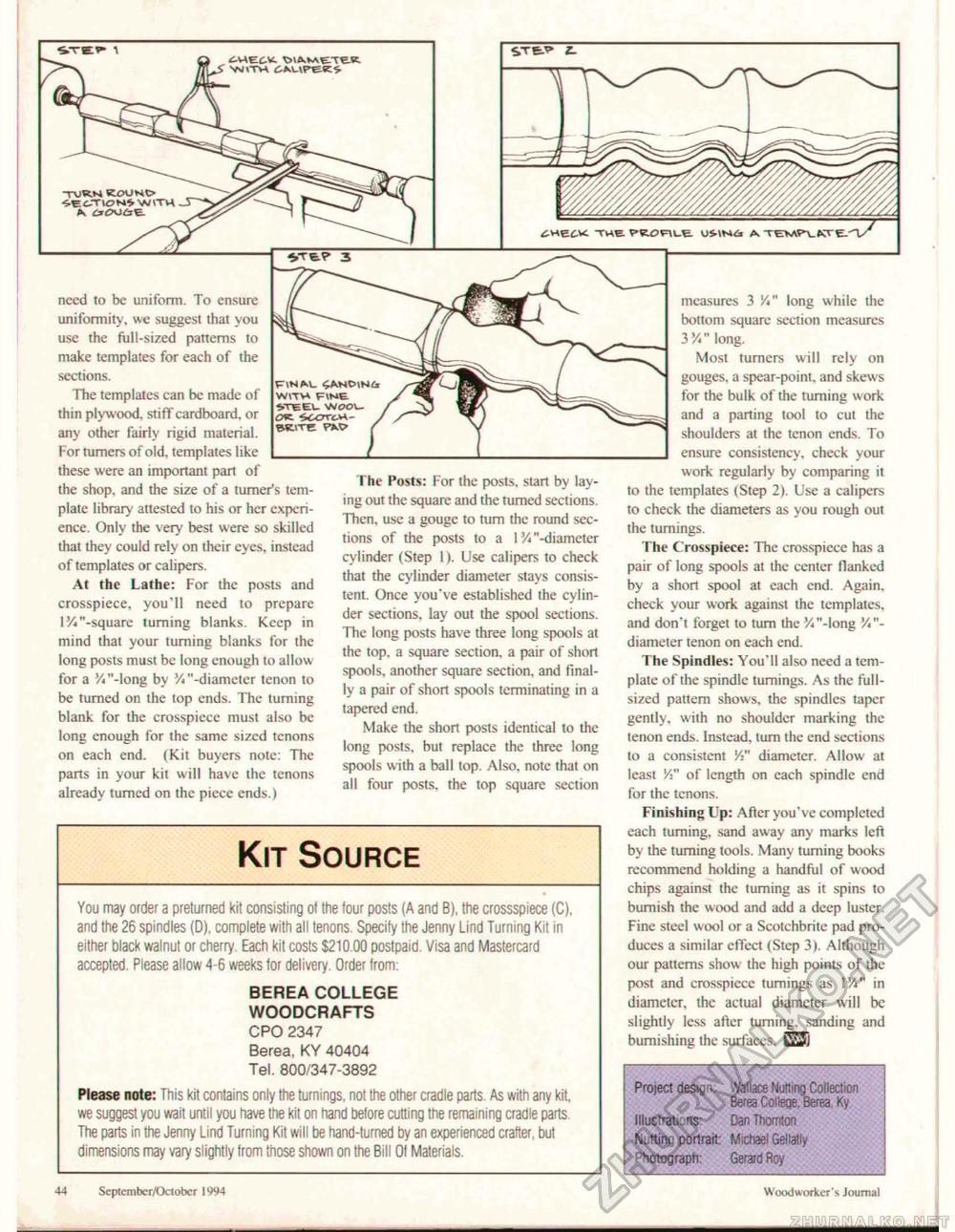

Kit Source You may order a preturned kit consisting of the four posts (A and B), the crossspiece (C), and the 26 spindles (D). complete with all tenons. Specify the Jenny Lind Turning Kit in either black walnut or cherry. Each kit costs $210.00 postpaid. Visa and Mastercard accepted. Please allow 4-6 weeks for delivery. Order from: BEREA COLLEGE WOODCRAFTS CPO 2347 Berea, KY 40404 Tel. 800/347-3892 Please note: This kit contains only the turnings, not the other cradle parts As with any kit. we suggest you wait until you have the kit on hand before cutting the remaining cradle parts The parts in the Jenny Lind Turning Kit will be hand-turned by an experienced crafter, but dimensions may vary slightly from those shown on the Bill Of Materials. Project design: Wallace Nutting Collection Berea College. Berea Ky Illustrations: Dan Thornton Nutting portrait: Michael Gellatly Photograph: Gerard Roy STfc*" Z. 4TEf 1 tHEtK WAhtAe.Te.5C. VJlTVA 3 need to be uniform. To ensure uniformity, we suggest that you use the full-sized patterns to make templates for each of the sections. The templates can be made of thin plywood, stiff cardboard, or any other fairly rigid material. For turners of old. templates like these were an important part of the shop, and the size of a turner's template library attested to his or her experience. Only the very best were so skilled that they could rely on their eyes, instead of templates or calipers. At the Lathe: For the posts and crosspiece, you'll need to prepare l%"-square turning blanks. Keep in mind that your turning blanks for the long posts must be long enough to allow for a y<"-long by V* "-diameter tenon to be turned on the top ends. The turning blank for the crosspiece must also be long enough for the same sized tenons on each end. (Kit buyers note: The pans in your kit will have the tenons already turned on the piecc ends.) WITV* FlME. SV^EU ViIOO\~ OK BKtre PM? The Posts: For the posts, start by laying out the square and the turned sections. Then, use a gouge to turn the round sections of the posts to a 1"-diameter cylinder (Step 1). Use calipers to check that the cylinder diameter stays consistent. Once you've established the cylinder sections, lay out the spool sections. The long posts have three long spools at the top. a square section, a pair of short spools, another square section, and finally a pair of short spools terminating in a tapered end. Make the short posts identical to the long posts, but replace the three long spools with a ball top. Also, note that on all four posts, the top square section measures 3 'A" long while the bottom square section measures 3long. Most turners will rely on gouges, a spear-point, and skews for the bulk of the turning work and a parting tool to cut the shoulders at the tenon ends. To ensure consistency, check your work regularly by comparing it to the templates (Step 2). Use a calipers to check the diameters as you rough out the turnings. The Crosspiece: The crosspicce has a pair of long spools at the center flanked by a short spool at each end. Again, check your work against the templates, and don't forget to turn the V-long Vi"-diameter tenon on each end. The Spindles: You'll also need a template of the spindle turnings. As the full-sized pattern shows, the spindles taper gently, with no shoulder marking the tenon ends. Instead, turn the end sections to a consistent '/" diameter. Allow at least !4" of length on each spindle end for the tenons. Finishing Up: After you've completed each turning, sand away any marks left by the turning tools. Many turning books recommend holding a handful of wood chips against the turning as it spins to burnish the wood and add a deep luster. Fine steel wool or a Scotchbrite pad produces a similar efTect (Step 3). Although our patterns show the high points of the post and crosspiece turnings as 1 Yt" in diameter, the actual diameter will be slightly less after turning, sanding and burnishing the surfaces. ^HEtVt THE. PRORLE USAHii A. 44 Septembcr/Ociobcr 1994 Woodworker's Journal |