Woodworker's Journal 2001-25-2, страница 31

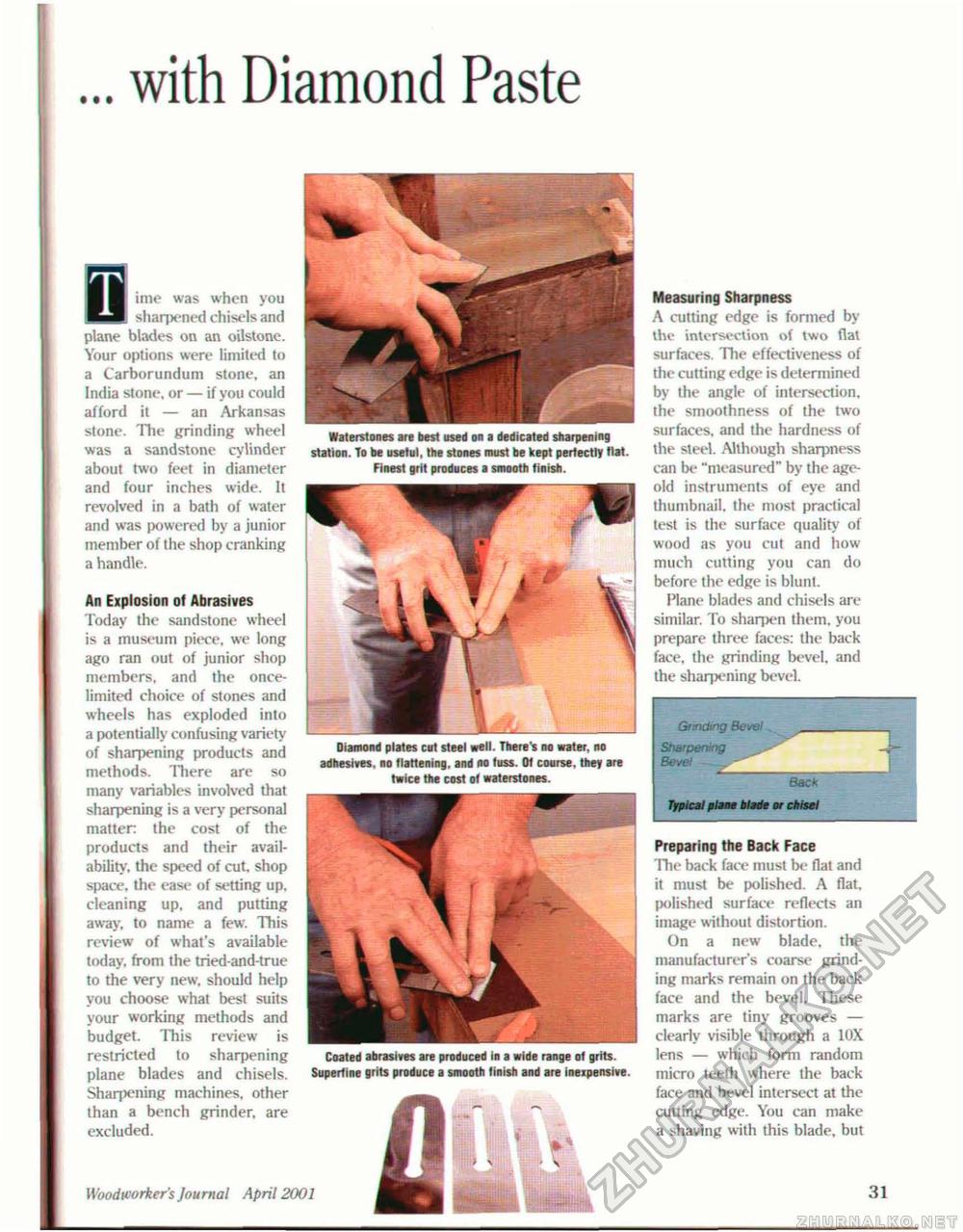

... with Diamond Paste ime was when you sharpened chisels and plane blades on an oilstone. Your options were limited to a Carborundum stone, an India stone, or — if you could afford it — an Arkansas stone. The grinding wheel was a sandstone cylinder about two feet in diameter and four inches wide. It revolved in a bath of water and was powered by a junior member of the shop cranking a handle. An Explosion of Abrasives Today the sandstone wheel is a museum piece, we long ago ran out of junior shop members, and the once-limited choice of stones and wheels has exploded into a potentially confusing variety of sharpening products and methods. There are so many variables involved that sharpening is a very personal matter the cost of the products and their availability, the speed of cut. shop space, the east3 of setting up, cleaning up. and putting away, to name a few. This review of what's available today, from the tried-and-true to the very new, should help you choose what best suits your working methods and budget. This review is restricted to sharpening plane blades and chisels. Sharpening machines, other than a bench grinder, are excluded. Woodworker 's Journal April 2001 Mtaterstones are best used on a dedicated sharpening station. To be useful, the stones must be kept perfectly flat. Finest grit produces a smooth finish. Diamond plates cut steel well. There's no water, no adhesives, no flattening, and no luss. Of course, they are twice the cost of waterstones. Coated abrasives are produced in a wide range of grits. Superfine grits produce a smooth finish and are inexpensive. Measuring Sharpness A cutting edge is formed by the intersection of two flat surfaces. The effectiveness of the cutting edge is determined by the angle of intersection, the smoothness of the two surfaces, and the hardness of the steel. Although sharpness can be "measured" by the age-old instruments of eye and thumbnail, the most practical test is the surface quality of wood as you cut and how much cutting you can do before the edge is blunt Plane blades and chisels are similar. To sharpen them, you prepare three faces: the back face, the grinding bevel, and the sharpening bevel. Grinding Bevel Sharpening Bevei Back Typical plane blade or chisel s Preparing the Back Face The back face must be flat and it must be polished. A flat, polished surface reflects an image without distortion. On a new blade, the manufacturer's coarse grinding marks remain on the back face and the bevel. These marks are tiny grooves — clearly visible through a 10X lens — which form random micro teeth where the back face and bevel intersect at the cutting edge. You can make a shaving with this blade, but 31 |