Woodworker's Journal 2001-25-2, страница 33

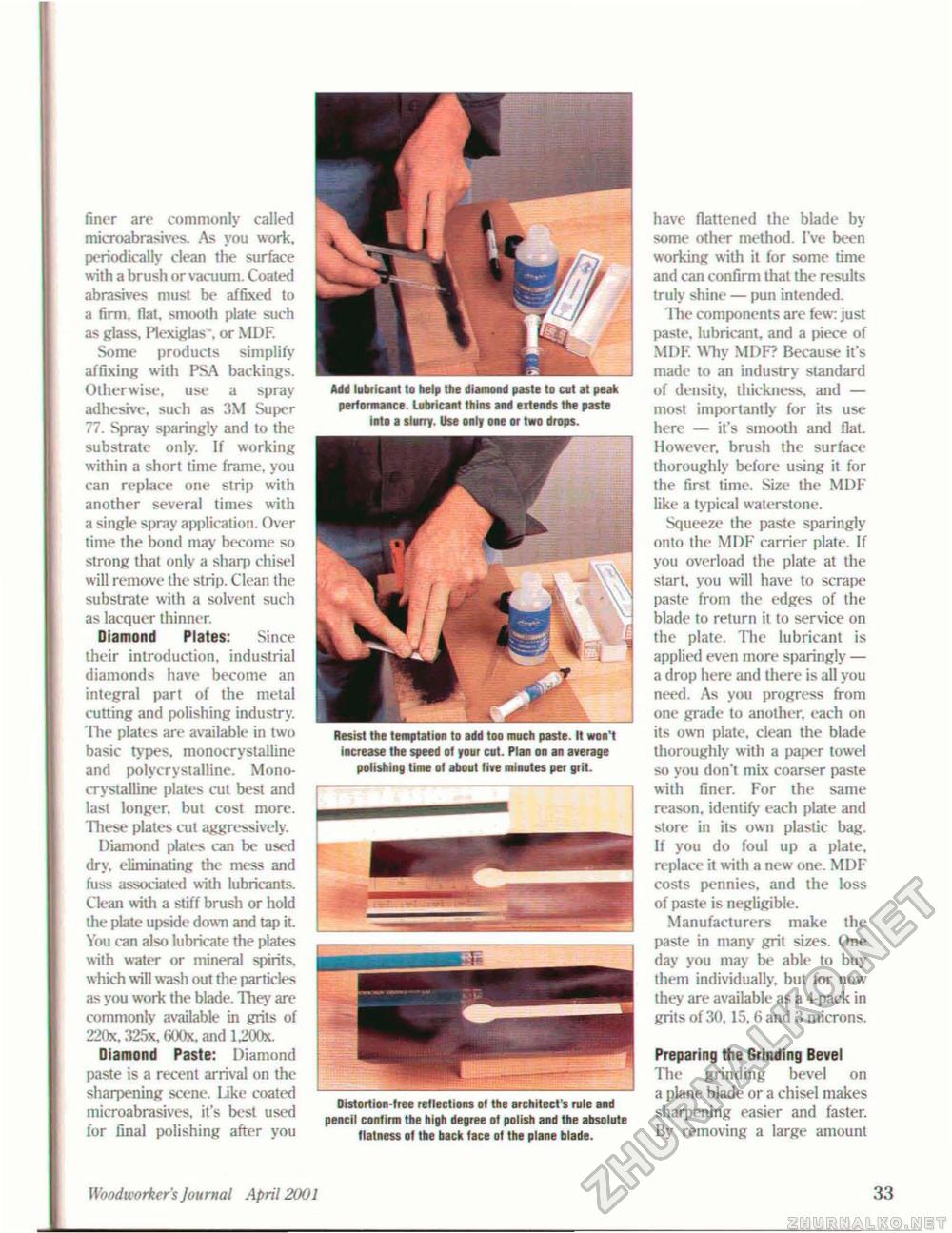

finer are commonly called microabrasives. As you work, periodically clean the surface with a brush or vacuum. Coated abrasives must be affixed to a firm. flal. smooth plate such as glass, Hexiglas ", or MDF. Some products simplify affixing with PSA backings. Otherwise, use a spray adhesive, such as 3M Super 77. Spray sparingly arid to the substrate only. If working within a short time frame, you can replace one strip wilh another several times with a single spray application. Over time the bond may become so strong that only a sharp chisel will remove the strip. Clean the substrate wilh a solvent such as lacquer thinner. Oiamond Plates: Since their introduction, industrial diamonds have become an integral part of the metal cutting and polishing industry. The plates are available in two basic types, monocrystalline and polvcrystalline. Mono-crystalline plates cut best and last longer, but cost more. These plates cut aggressively. Diamond plates can be used dry. eliminating the mess and fuss associated with lubricants. Clean with a stiff brush or hold ihe plate upside down and tap it. You can also lubricate the plates with water or mineral spirits, which will wash out the particles as you work the blade. They are commonly available in grils of 220x. 325x, (KJOx. and U'OOx. Diamond Paste: Diamond paste is a recent arrival on the sharpening scene. Like coated microabrasives, it's best used for final polishing after you have flattened the blade by some other method. I've been working with it for some time and can confirm that die results truly shine — pun intended. The components are few: just paste, lubricant, and a piece of MDF. Why MDF? Because it's made to an industry standard of density, thickness, and — mosl importantly for its use here — it's smooth and flat. However, brush the surface thoroughly before using it for the first time. Size the MDF like a typical waterstone. Squeeze the paste sparingly onto the MDF carrier plate. If you overload the plate at the start, you will have to scrajie paste from the edges of ihe blade to return it to service on the plate. The lubricant is applied even more sparingly — a drop here and there is all you need. As you progress from one grade to another, each on its own plate, clean the blade thoroughly with a paper towel so you don't mix coarser paste with finer. For the same reason, identify each plate and store in its own plastic bag. If you do foul up a plate, replace it with a new one. MDF costs pennies, and the loss of paste is negligible. Manufacturers make the paste in many grit sizes. One day you may be able to buy them individually, but for now they are available as a 4-pack in grits of 30, 15. 6 and 3 microns. Resist the temptation to add too much paste. It won't increase Ihe speed ol your cut. Plan on an average polishing time ol about five miuutes per grit. Add lubricant to help the diamond paste to cut at peak performance. Lubricant thins and eitends the paste into a slurry. Use only one or two drops. Distortion-tree reflections ol the architect's rule and pencil confirm the high degree ol polish and the absolute flatness of the back lace ol the plane blade. Preparing the Grinding Bevel The grinding bevel on a plane blade or a chisel makes sharpening easier and faster. By removing a large amount Woodworker 's Journal April 2001 33 |