Woodworker's Journal 2001-25-2, страница 35

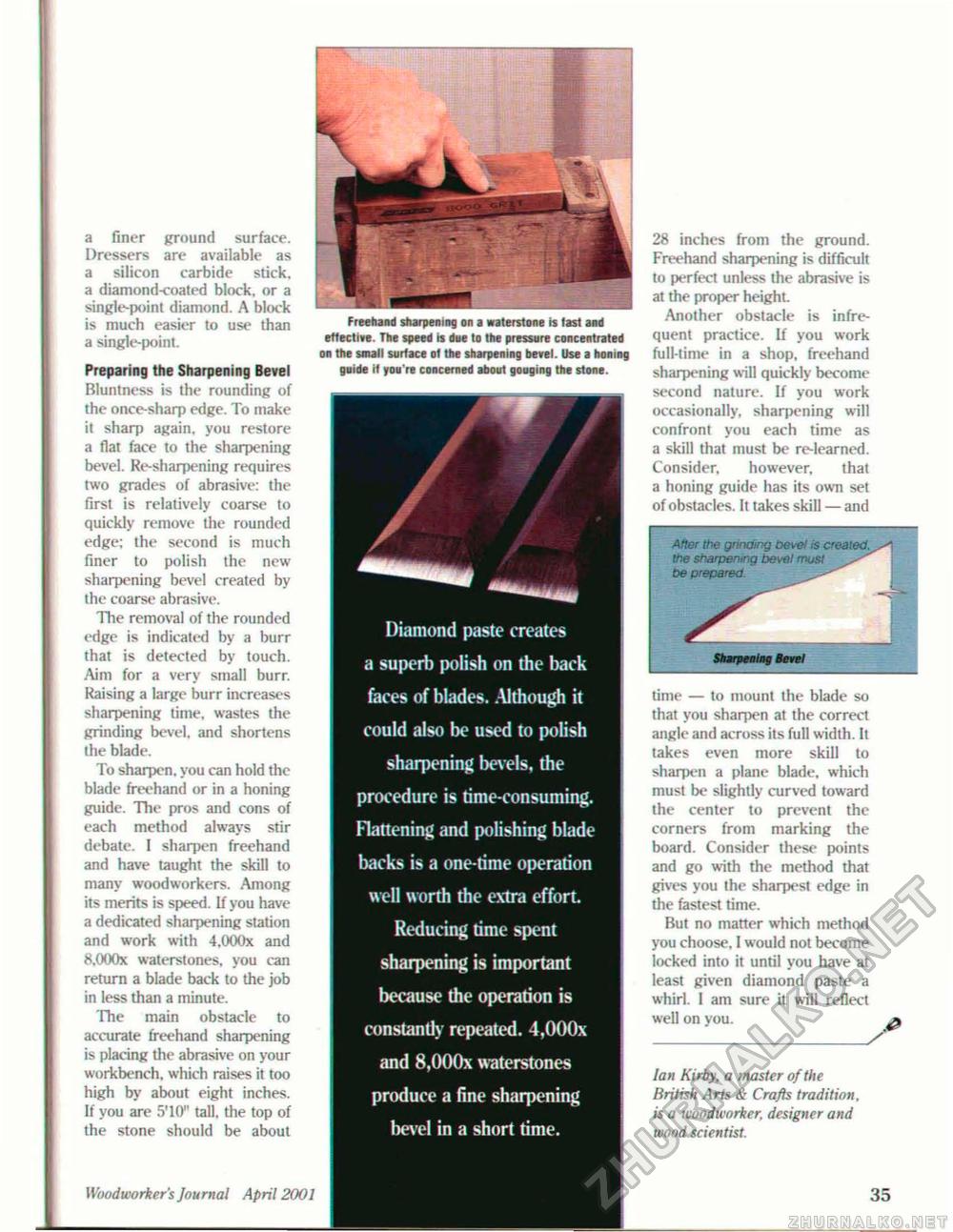

a finer ground surface. Dressers are available as a silicon carbide stick, a diamond-coated block, or a single-point diamond. A block is much easier to use than a single-point. Preparing the Sharpening Bevel Bluntness is the rounding of the once-sharp edge. To make it sharp again, you restore a flat face to the sharpening bevel. He-sharpening requires two grades of abrasive: the first is relatively coarse to quickly remove the rounded edge; the second is much finer to polish the new sharpening bevel created by the coarse abrasive. The removal of the rounded edge is indicated by a burr that is detected by touch. Aim for a very small burr. Raising a large burr increases sharpening time, wastes the grinding bevel, and shortens the blade. To sharpen, you can hold the blade freehand or in a honing guide. The pros and cons of each method always stir debate. I sharpen freehand and have taught the skill to many woodworkers. Among its merits is speed. If you have a dedicated sharpening station and work with 4,000x and 8.000x waterstones, you can return a blade back to the job in less than a minute. The main obstacle to accurate freehand sharpening is placing the abrasive on your workbench, which raises it too high by about eight inches. If you are 5*10" tall, the top of the stone should be about Freehand sharpening on a waterstone is fast and effective. The speed is due to the pressure concentrated on the small surface of the sharpening bevel. Use a honing guide if you're concerned about gouging the stone. Diamond paste creates a superb polish on the back faces of blades. .Although it could also be used to polish sharpening bevels, the procedure is time-consuming. Flattening and polishing blade backs is a one-time operation well worth the extra effort. Reducing time spent sharpening is important because the operation is constant!)' repeated. 4,000x and 8,000x waterstones produce a fine sharpening bevel in a short time. 28 inches from the ground. Freehand sharpening is difficult to perfect unless the abrasive is at the proper height. Another obstacle is infrequent practice. If you work full-time in a shop, freehand sharpening will quickly become second nature. If you work occasionally, sharpening wilt confront you each time as a skill that must be re-learned. Consider. however, that a honing guide has its own set of obstacles. It takes skill — and After the grinding beve! is created.^ the sharpening bevel must be prepared. Sharpening Bevel time — to mount the blade so that you sharpen at the correct angle and across its full width. It takes even more skill to sharpen a plane blade, which must be slightly curved toward the center to prevent the corners from marking the board. Consider these points and go with the method that gives you the sharpest edge in the fastest time. But no matter which method you choose. I would not become locked into it until you have at least given diamond paste a whirl. I am sure it will reflect well on you. Ian Kirby, a master of the British Arts & Crafts tradition, is a woodworker, designer and wood scientist. Woodworker 's Journal April 2001 35 |