Woodworker's Journal 2001-25-2, страница 34

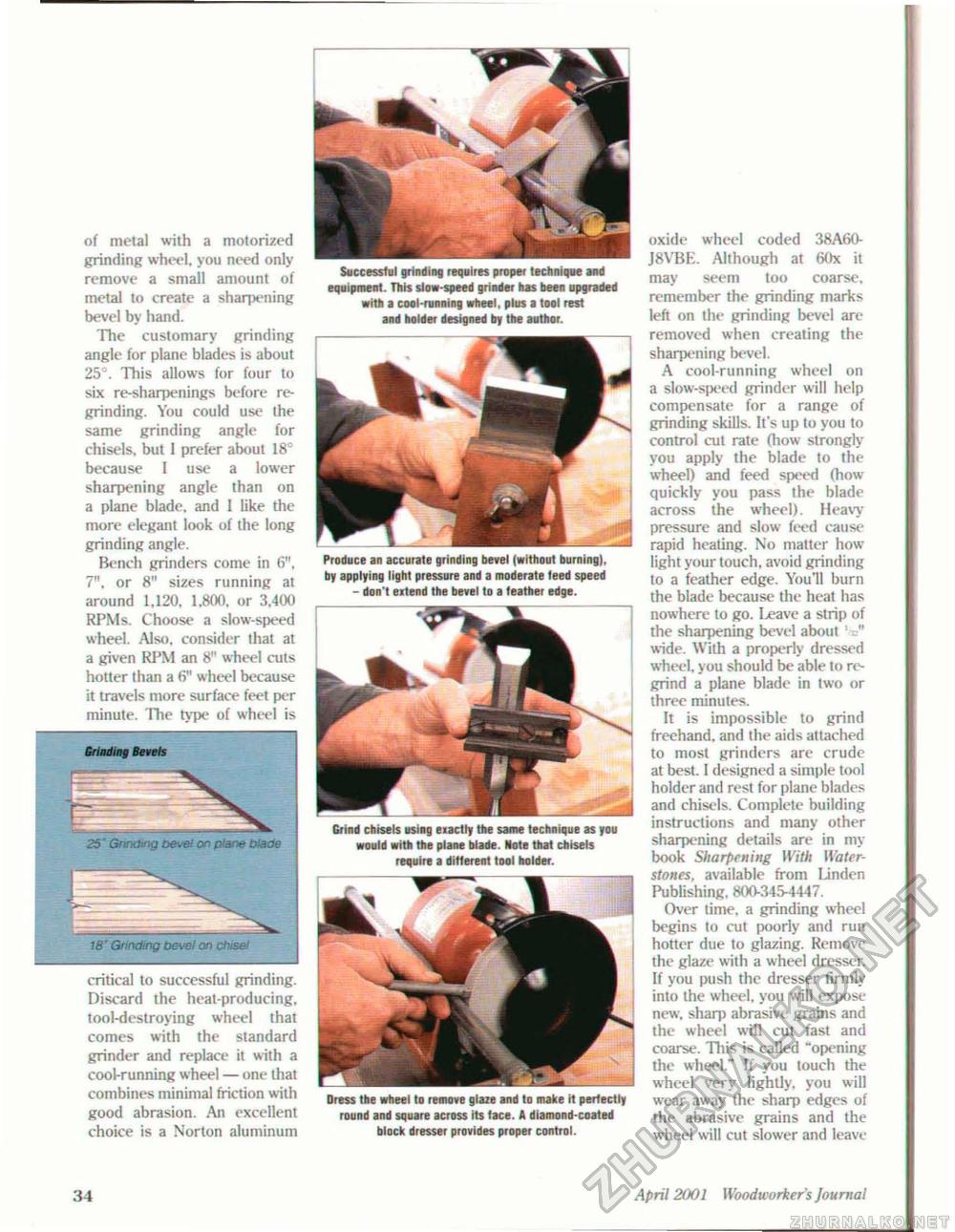

of metal with a motorized grinding wheel, you need only remove a small amount of metal to create a sharj>eiiing bevel by hand. The customary grinding angle for plane blades is about 25°. This allows for four to six re-sharpenings before re-grinding. You could use the same grinding angle for chisels, but I prefer about 18° because I use a lower sharpening angle than on a plane blade, and 1 like the more elegant look of the long grinding angle. Bench grinders come in 6", 7", or 8" sizes running at around 1,120. 1,800, or 3.400 RPMs. Choose a slow-speed wheel. Also, consider that at a given RP\1 an 8" wheel cuts hotter than a 6" wheel because it travels more surface feet per minute. The type of wheel is Grinding Bevels 25' Grinding bevel on plane blade 18' Grinding bevel on chisel critical to successful grinding. Discard ihe heat-producing, tool-destroying wheel that comes with the standard grinder and replace it with a cool-running wheel — one that combines minimal friction with good abrasion. An excellent choice is a Norton aluminum Successful grinding requires proper technique and equipment. This slow-speed grinder has been upgraded with a cool-running wheel, plus a tool rest and holder designed by the author. Produce an accurate grinding bevel (without burning), by applying light pressure and a moderate leed speed - don'l extend the bevel to a feather edge. Grind chisels using exactly the same technique as you would with the plane blade. Note that chisels require a different tool holder. Dress the wheel to remove glaie and to make it perfectly round and square across its lace. A diamond-coated block dresser provides proper control. oxide wheel coded 38A60-J8VBE. Although at 60x it may seem too coarse, remember the grinding marks left on the grinding bevel are removed when creating the sharpening bevel. A cool-running wheel on a slow-speed grinder will help compensate for a range of grinding skills. It's up to you to control cut rate (how strongly you apply the blade to the wheel) and feed speed (how quickly you pass the blade across the wheel). Heavy pressure and slow feed cause rapid heating. No matter how tight your touch, avoid grinding to a feather edge. You'll burn the blade because the heat has nowhere to go. I^ave a strip of the sharpening bevel about V wide. With a properly dressed wheel, you should be able to re-grind a plane blade in two or three minutes. It is impossible to grind freehand, and the aids attached to most grinders are crude at best. I designed a simple tool holder and rest for plane blades and chisels. Complete building instructions and many other sharpening details are in my book Sharpening With Waterstones, available from Linden Publishing. 800-3454447. Over time, a grinding wheel begins to cut poorly and run hotter due to glazing. Remove the glaze with a wheel dresser. If you push the dresser firmly into the wheel, you will expose new, sharp abrasive grains and the wheel will cut fast and coarse. This is called "opening the wheel." If you touch the wheel very lightly, you will wear away the sharp edges of the abrasive grains and the wheel will cut slower and leave 34 April 2001 Woodworker's Journal |