Woodworker's Journal 2004-28-6, страница 19

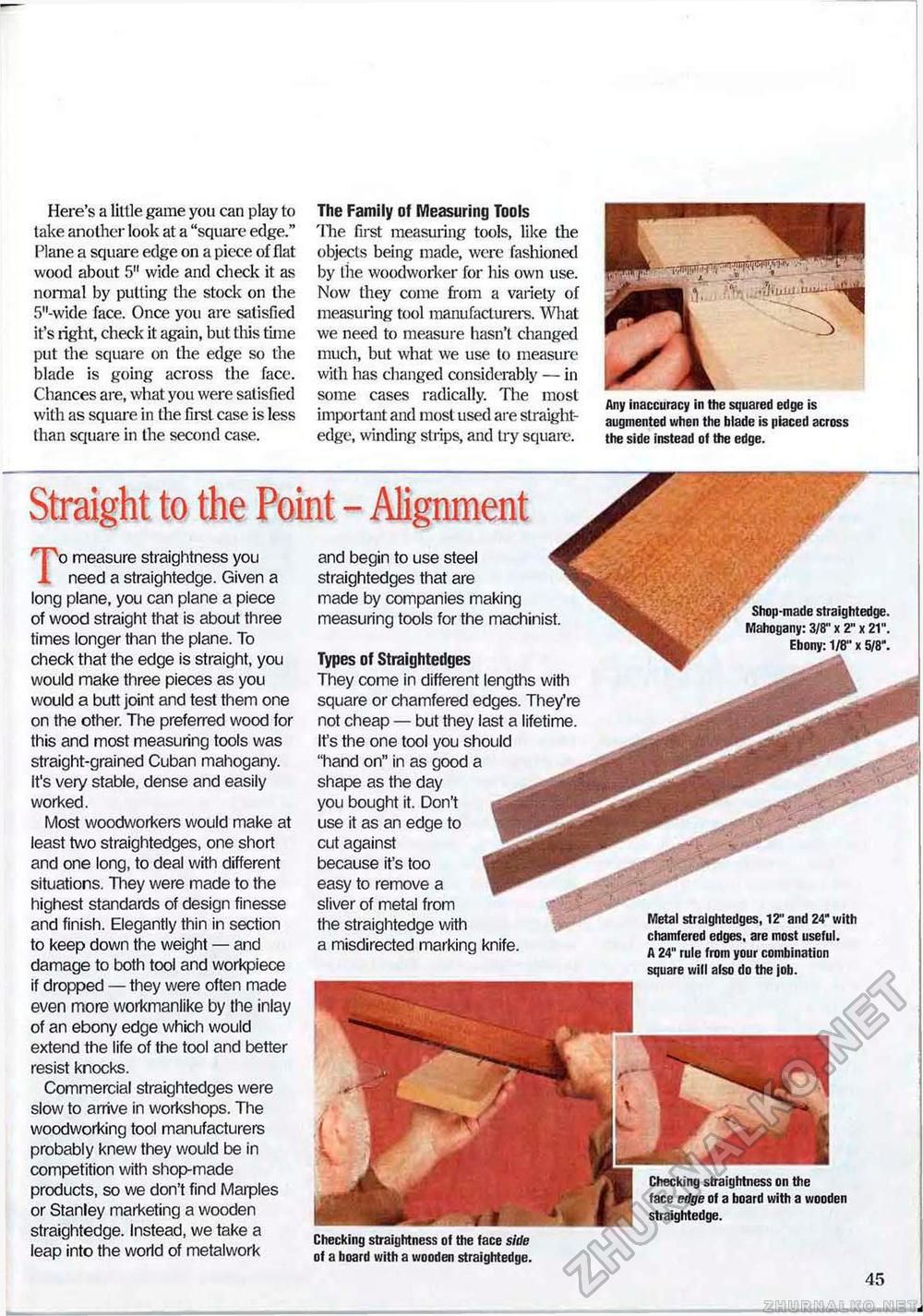

Here's a little game you can play to take another look at a "square edge." Plane a square edge on a piece of flat wood about 5" wide and check it as normal by putting the stock on the 5"-wide face. Once you are satisfied it's right, check it again, but this time put the square on the edge so the blade is going across the face. Chances are, what you were satisfied with as square in the first case is less than square in the second case. The Family of Measuring Tools 'Hie first measuring tools, like the objects being made, were fashioned by the woodworker for his own use. Now they come from a variety of measuring tool manufacturers. What we need to measure hasn't changed much, but what we use to measure with has changed considerably — in some cases radically. The most important and most used are straightedge, winding strips, and try square. Any inaccuracy in the squared edge is augmented when the blade is placed across the side instead of the edge. Straight to the Point - Alignment To measure straightness you need a straightedge. Given a long plane, you can plane a piece of wood straight that is about three times longer than the plane. To check that the edge is straight, you would make three pieces as you would a butt joint and test them one on the other. The preferred wood for this and most measuring tools was straight-grained Cuban mahogany. It's very stable, dense and easily worked. Most woodworkers would make at least two straightedges, one short and one long, to deal with different situations. They were made to the highest standards of design finesse and finish. Elegantly thin in section to keep down the weight — and damage to both tool and workpiece if dropped — they were often made even more workmanlike by the inlay of an ebony edge which would extend the life of the tool and better resist knocks. Commercial straightedges were slow to arrive in workshops. The woodworking tool manufacturers probably knew they would be in competition with shop-made products, so we don't find Marples or Stanley marketing a wooden straightedge. Instead, we take a leap into the world of metalwork and begin to use steel straightedges that are made by companies making measuring tools for the machinist. Types of Straightedges They come in different lengths with square or chamfered edges. They're not cheap — but they last a lifetime. It's the one tool you should "hand on" in as good a shape as the day you bought it. Don't use it as an edge to cut against because it's too easy to remove a sliver of metal from the straightedge with a misdirected marking knife. Shop-made straightedge. Mahogany: 3/8" x 2" x 21". Ebony: 1/8" x 5/8". Metal straightedges, 12' and 24" with chamfered edges, are most useful. A 24" rule from your combination square will also do the job. Checking straightness on the face edge of a board with a wooden straightedge. Checking straightness of the face side of a board with a wooden straightedge. 45 |