Woodworker's Journal 2004-28-6, страница 21

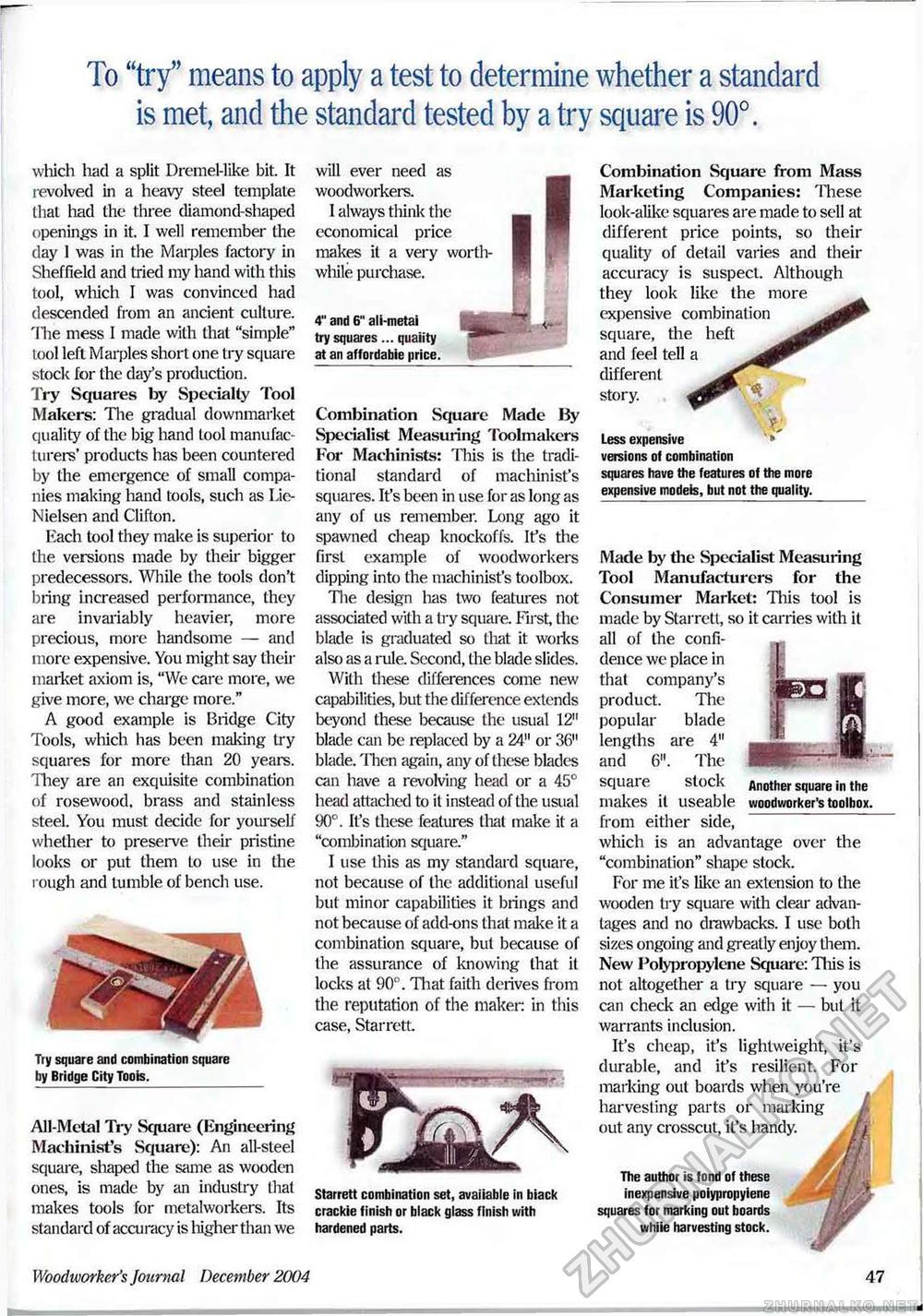

To "try" means to apply a test to determine whether a standard is met, and the standard tested by a try square is 90°. which had a split Dremel-like bit. It revolved in a heavy steel template that had the three diamond-shaped openings in it. I well remember the day 1 was in the Marples factory in Sheffield and tried my hand with this tool, which I was convinced had descended from an ancient culture. 'Hie mess I made with that "simple" tool left Marples short one try square stock for the day's production. Try Squares by Specialty Tool Makers: The gradual downmarket quality of the big hand tool manufacturers' products has been countered by the emergence of small companies making hand tools, such as Lie-Nielsen and Clifton. Each tool they make is superior to the versions made by their bigger predecessors. While the tools don't bring increased performance, they are invariably heavier, more precious, more handsome — and more expensive. You might say their market axiom is, "We care more, we give more, we charge more." A good example is Bridge City Tools, which has been making try squares for more than 20 years. They are an exquisite combination of rosewood, brass and stainless steel. You must decide for yourself whether to preserve their pristine looks or put them to use in the rough and tumble of bench use. Try square and combination square by Bridge City Toois. All-Metal Try Square (Engineering Machinist's Square): An all-steel square, shaped the same as wooden ones, is made by an industry that makes tools for metalworkers. Its standard of accuracy is higher than we will ever need as woodworker's. I always think the economical price makes it a very worthwhile purchase. 4" and 6" ali-metai try squares... quality at an affordable price. Combination Square Made By Specialist Measuring Toolmakers For Machinists: This is the traditional standard of machinist's squares. It's been in use for as long as any of us remember. Long ago it spawned cheap knockoffs. It's the first example of woodworkers dipping into the machinist's toolbox. The design has two features not associated with a try square. First, the blade is graduated so that it works also as a rule. Second, the blade slides. With these differences come new capabilities, but the difference extends beyond these because the usual 12" blade can be replaced by a 24" or 36" blade. Then again, any of these blades can have a revolving head or a 45° head attached to it instead of the usual 90c. It's these features that make it a "combination square." I use this as my standard square, not because of the additional useful but minor capabilities it brings and not because of add-ons that make it a combination square, but because of the assurance of knowing that it locks at 90°. That faith derives from the reputation of the maker: in this case, Starrett. Combination Square from Mass Marketing Companies: These look-alike squares are made to sell at different price points, so their quality of detail varies and their accuracy is suspect. Although they look like the more expensive combination square, the heft and feel tell a different ^^ story. Jw** ^L \ Less expensive * versions of combination squares have the features of the more expensive models, but not the quality. Starrett combination set, available in biack crackie finish or black glass finish with hardened parts. Made by the Specialist Measuring Tool Manufacturers for the Consumer Market: This tool is made by Starrett, so it carries with it all of the confidence we place in that company's product. The popular blade lengths are 4" and 6". The square stock Another square in the makes it useable woodworker's toolbox, from either side, which is an advantage ovei* the "combination" shape stock. For me it's like an extension to the wooden try square with clear advantages and no drawbacks. I use both sizes ongoing and greatly enjoy them. New Polypropylene Square: Tliis is not altogether a try square — you can check an edge with it — but it warrants inclusion. It's cheap, it's lightweight, it's durable, and it's resilient. For marking out boards when you're harvesting parts or marking out any crosscut, it's handy. j fl The author is fond of these inexpensive poiypropyiene squares for marking out boards whiie harvesting stock. Woodworker's Journal Decernber 2004 47 |