Woodworker's Journal 2004-28-6, страница 23

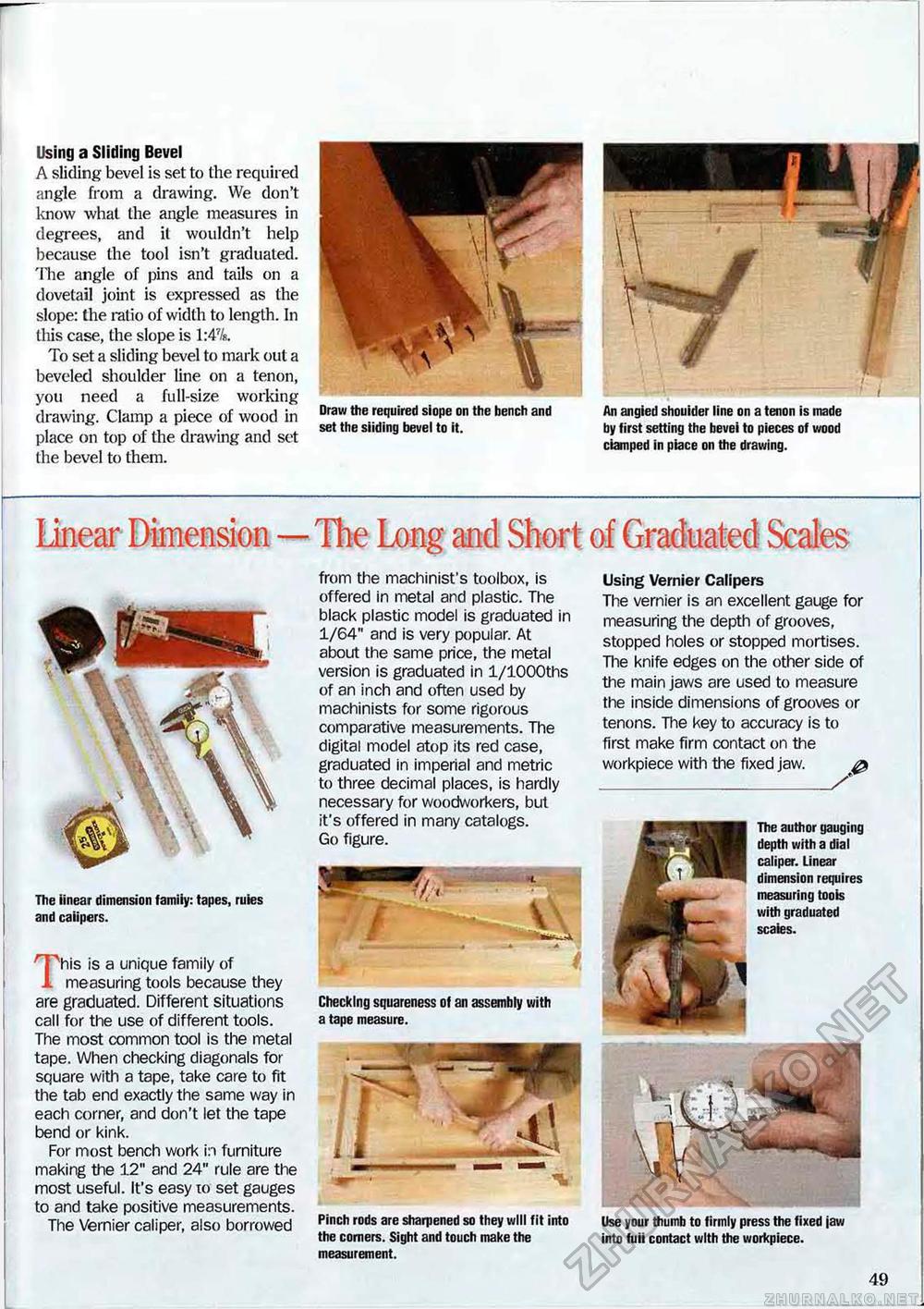

Using a Sliding Bevel A sliding bevel is set to the required angle from a drawing. We don't know what the angle measures in degrees, and it wouldn't help because the tool isn't graduated. The angle of pins and tails on a dovetail joint is expressed as the slope: the ratio of width to length. In this case, the slope is 1:4%. To set a sliding bevel to mark out a beveled shoulder line on a tenon, you need a full-size working drawing. Clamp a piece of wood in place on top of the drawing and set the bevel to them. Draw the required siope on the bench and set the sliding bevel to it. An angied shouider line on a tenon is made by first setting the bevei to pieces of wood ciamped in place on the drawing. The iinear dimension family: tapes, rules and calipers. from the machinist's toolbox, is offered in metal and plastic. The black plastic model is graduated in 1/64" and is very popular. At about the same price, the metal version is graduated in l/1000ths of an inch and often used by machinists for some rigorous comparative measurements. The digital model atop its red case, graduated in imperial and metric to three decimal places, is hardly necessary for woodworkers, but it's offered in many catalogs. Go figure. i Mid is a unique family of 1 measuring tools because they are graduated. Different situations call for the use of different tools. The most common tool is the metal tape. When checking diagonals for square with a tape, take care to fit the tab end exactly the same way in each corner, and don't let the tape bend or kink. For most bench work in furniture making the 12" and 24" rule are the most useful. It's easy to set gauges to and take positive measurements. The Vernier caliper, also borrowed Using Vernier Calipers The vernier is an excellent gauge for measuring the depth of grooves, stopped holes or stopped mortises. The knife edges on the other side of the main jaws are used to measure the inside dimensions of grooves or tenons. The key to accuracy is to first make firm contact on the workpiece with the fixed jaw. jp flBQMB The author gauging Mgj^^^^H depth with a dial caliper. Linear T ^^^^ dimension requires ij^K^f^ measuring tools with graduated scales. Pinch rods are sharpened so they will fit into the comers. Sight and touch make the measurement. Checking squareness of an assembly with a tape measure. Use your thumb to firmly press the fixed jaw into fuii contact with the workpiece. 49 |