Woodworker's Journal 2004-28-6, страница 8

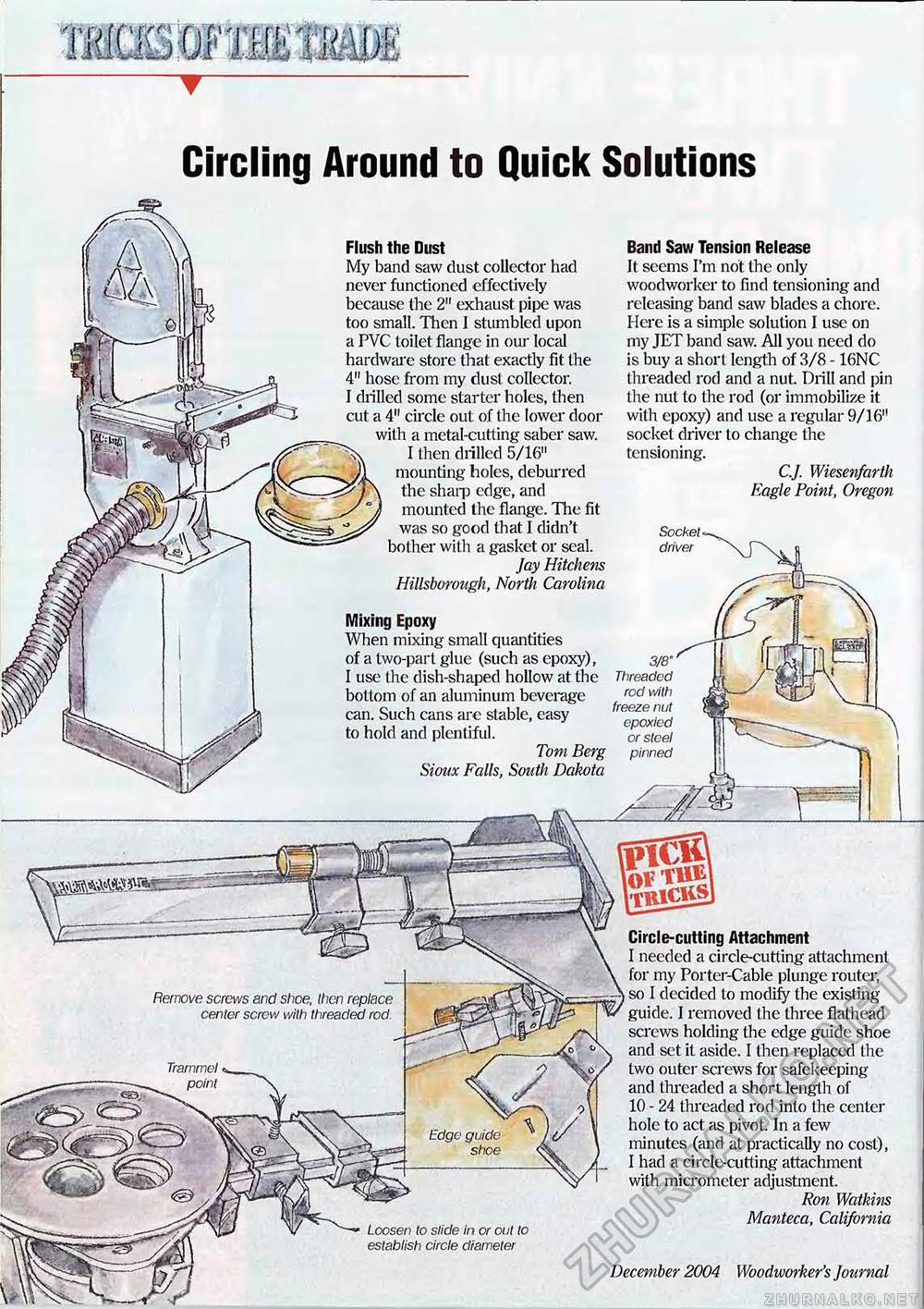

iMMmM&mm ▼ Circling Around to Quick Solutions Circle-cutting Attachment I needed a circle-cutting attachment for my Porter-Cable plunge router, so I decided to modify the existing guide. I removed the three flathead screws holding the edge guide shoe and set it aside. I then replaced the two outer screws for safekeeping and threaded a short length of 10 - 24 threaded rod into the center hole to act as pivot. In a few minutes (and at practically no cost), I had a circle-cutting attachment willi micrometer adjustment Ron Watkins Manteca, California 8 December 2004 Woodworker's Journal Trammel Edge guide shoe Loosen to slide in or out to establish circle diameter Flush the Dust My band saw dust collector had never functioned effectively because the 2" exhaust pipe was too small. Then I stumbled upon a PVC toilet flange in our local hardware store that exactly fit the 4" hose from my dust collector. I drilled some starter holes, then cut a 4" circle out of the lower door with a metal-cutting saber saw. I then drilled 5/16" mounting holes, deburred the shaip edge, and mounted the flange. The fit was so good that I didn't bother with a gasket or seal. Jay Hitchens Hillsborough, North Carolina Mixing Epoxy When mixing small quantities of a two-part glue (such as epoxy), I use the dish-shaped hollow at the bottom of an aluminum beverage can. Such cans are stable, easy to hold and plentiful. Tom Berg Sioux Falls, South Dakota 3/8" Threaded rod with freeze nut epoxied or steel pinned Remove screws and shoe, then replace center screw with threaded rod Band Saw Tension Release It seems Pm not the only woodworker to find tensioning and releasing band saw blades a chore. Here is a simple solution I use on my JET band saw. All you need do is buy a short length of 3/8 - 16NC threaded rod and a nut. Drill and pin the nut to the rod (or immobilize it with epoxy) and use a regular 9/16" socket driver to change the tensioning. C.J. Wiesenfarth Eagle Point, Oregon driver |