Woodworker's Journal 2004-28-6, страница 10

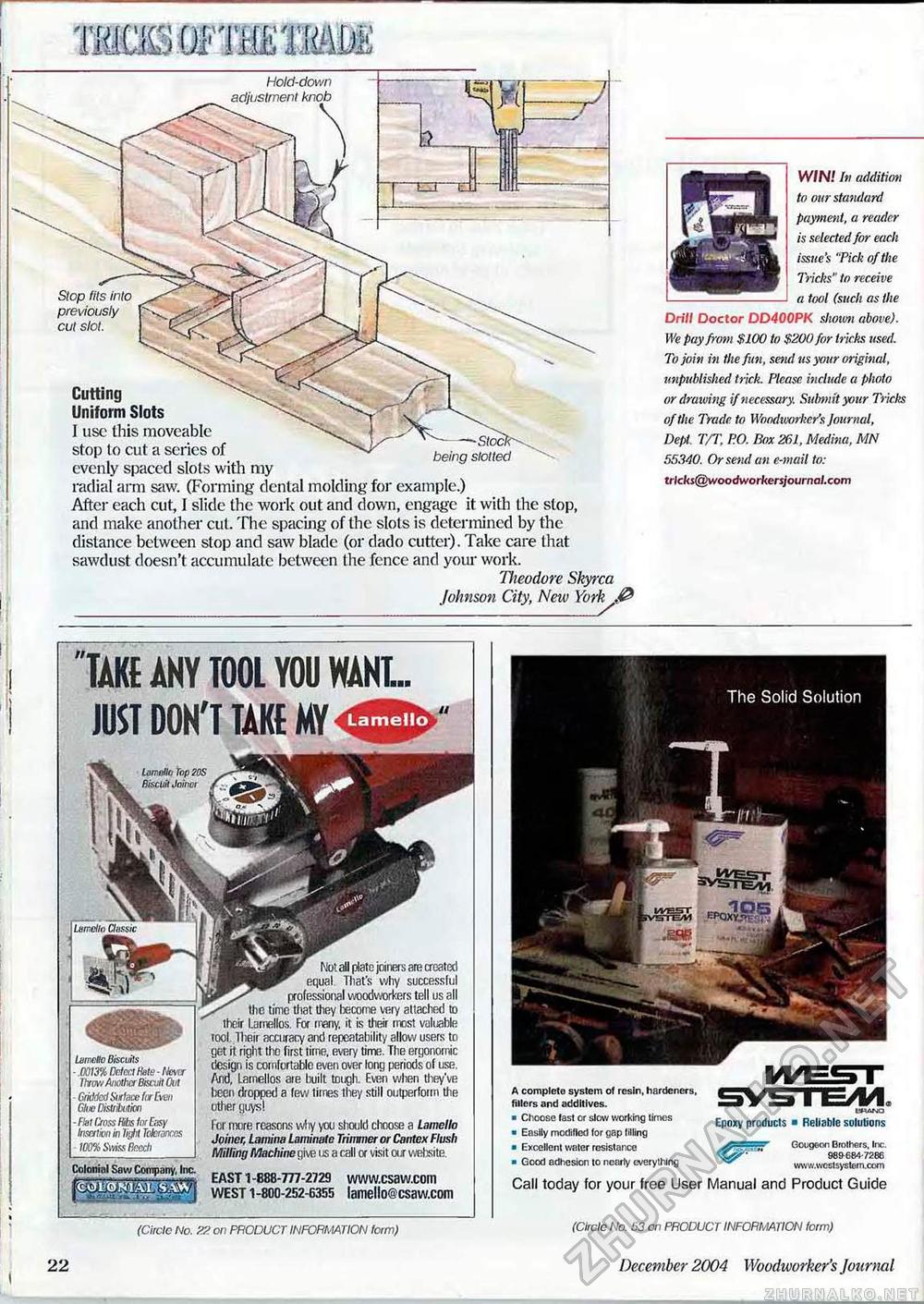

nmmrn'mm Lamitllo Top 20S Biscuit Joiner Lamello Classic Colonial Saw Company, Inc. TAKE ANY TOOL YOU WANT. JUST DON'T TAKE MY Lamello Lsmetto Biscuits -.0013% Detect Hate-Never Throw AnotherBiscuit Chit Gridded Surface for Even Glue Distribution - Flat Cross Hibs tor Easy Insertion in Tight Tolcrances 100% Swiss Beech Not all plate joiners are created equal That's why successful professional woodworkers tell us all the time that they become very attached to iheir l.amellos. Fa many, it is their most valuable rool llieir accuracy and repeatability allow users to get it right the first time, every time. The economic design is comfortable even over long periods of use. And. Lamellos are built tough. Even when they've teen dropped a few times they still outperform the other guys! For more reasons why you should choose a Lamello Joiner, Lamina Laminate Trimmer or Cantex Flush Milling Machine give us a call or visit air website. EAST 1 -888-777-2729 www.csaw.com WEST 1-800-252-6355 lamello@csaw.com (Circle No. 22 on PRODUCT INFORMATION form) (Circle No. 53 on PRODUCT INFORMATION form) Hold-down WIN! In addition to our standard payment, a reader is selected for each issue's "Pick of the Tricks" to receive a tool (such as the Drill Doctor DD400PK showi above). We pay from $100 to $200for tricks used. To join hi the fun, send us your original, unpublished trick. Please include a photo or drawing if necessary. Sutmiit your Tricks of the Trade to Woodworker's Journal, Dept. T/T, P.O. Box 261, Medina, MN 55340. Or send an e-mail to: trtcks@woodworkersjournal.com A complete system of resin, hardeners, fillers and additives. ■ Choose fast or slow working times ■ Easily modified for gap filling ■ Excellent water resistance ■ Good adhesion to nearly everything Call today for your free User BMANQ Epoxy products ■ Reliable solutions Gougeon Brothers, Inc. 989-684-7286 www.wcstsystem.com Manual and Product Guide nauGM un Slop fits into previously cut slot. Cutting Uniform Slots I use this moveable stop to cut a series of evenly spaced slots with my """ ~ radial arm saw. (Forming dental molding for example.) After each cut, I slide the work out and down, engage it with the stop, and make another cut. The spacing of the slots is determined by the distance between stop and saw blade (or dado cutter). Take care that sawdust doesn't accumulate between the fence and your work. Theodore Skyrca _Johnson City, New York 22 I December 2004 Woodworker's Journal |