Woodworker's Journal 2004-Winter, страница 14

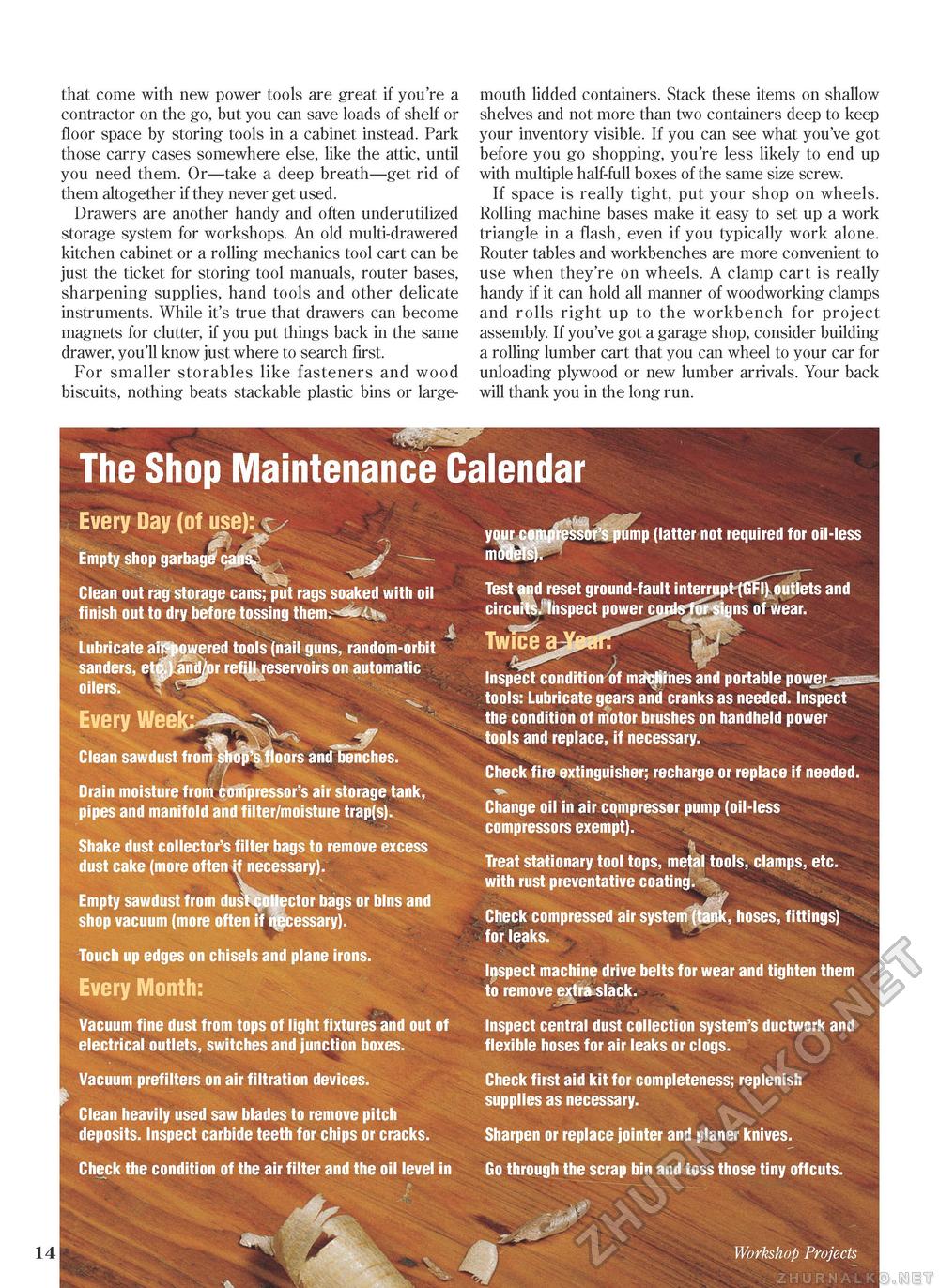

that come with new power tools are great if you're a contractor on the go, but you can save loads of shelf or floor space by storing tools in a cabinet instead. Park those carry cases somewhere else, like the attic, until you need them. Or—take a deep breath—get rid of them altogether if they never get used. Drawers are another handy and often underutilized storage system for workshops. An old multi-drawered kitchen cabinet or a rolling mechanics tool cart can be just the ticket for storing tool manuals, router bases, sharpening supplies, hand tools and other delicate instruments. While it's true that drawers can become magnets for clutter, if you put things back in the same drawer, you'll know just where to search first. For smaller storables like fasteners and wood biscuits, nothing beats stackable plastic bins or large- mouth lidded containers. Stack these items on shallow shelves and not more than two containers deep to keep your inventory visible. If you can see what you've got before you go shopping, you're less likely to end up with multiple half-full boxes of the same size screw. If space is really tight, put your shop on wheels. Rolling machine bases make it easy to set up a work triangle in a flash, even if you typically work alone. Router tables and workbenches are more convenient to use when they're on wheels. A clamp cart is really handy if it can hold all manner of woodworking clamps and rolls right up to the workbench for project assembly. If you've got a garage shop, consider building a rolling lumber cart that you can wheel to your car for unloading plywood or new lumber arrivals. Your back will thank you in the long run. The Shop Maintenance Calendar Every Day (of use): c Empty shop garbage cans. ; Clean out rag storage cans; put rags soaked with oil finish out to dry before tossing them. Lubricate air-powered tools (nail guns, random-orbit sanders, etc.) . and/or refill reservoirs on automatic oilers. ^ Every Weefc-r>-x, v Clean sawdust from shop's floors and benches. Drain moisture from compressor's air storage tank, pipes and manifold and filter/moisture trap(s). Shake dust collector's filter bags to remove excess dust cake (more often if necessary). Empty sawdust from dust collector bags or bins and shop vacuum (more often if necessary). Touch up edges on chisels and plane irons. Every Month: Vacuum fine dust from tops of light fixtures and out of electrical outlets, switches and junction boxes. Vacuum prefilters on air filtration devices. Clean heavily used saw blades to remove pitch deposits. Inspect carbide teeth for chips or cracks. ssor's pump (latter not required for oil-less Test and reset ground-fault interrupt (GFI) outlets and circuits. Inspect power cords for signs of wear. TwiceaJeaT Inspect condition of machines and portable power tools: Lubricate gears and cranks as needed. Inspect the condition of motor brushes on handheld power tools and replace, if necessary. Check fire extinguisher; recharge or replace if needed. Change oil in air compressor pump (oil-less compressors exempt). |k Treat stationary tool tops, metal tools, clamps, etc. with rust preventative coating. Check compressed air system for leaks. , hoses, fittings) Inspect machine drive belts for wear and tighten them to remove extra slack. -J® Inspect central dust collection system's ductwork and flexible hoses for air leaks or clogs. Check first aid kit for completeness; replenish supplies as necessary. Sharpen or replace jointer and planer knives. Check the condition of the air filter and the oil level in Go through the scrap bin and toss those tiny offcuts. 14 * Workshop Projects |