Woodworker's Journal 2004-Winter, страница 31

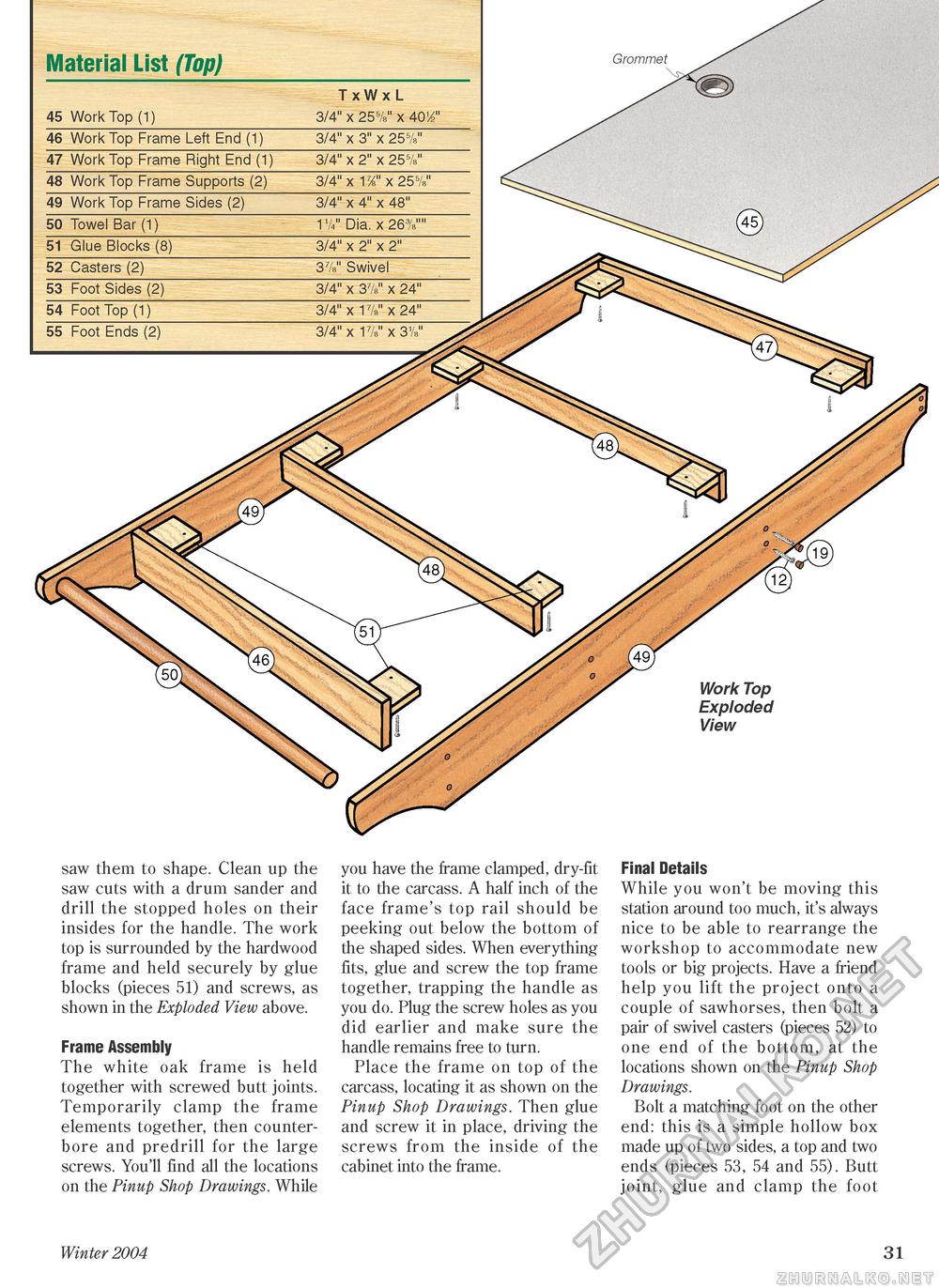

Material List (Top)

Grommet @ (47) (481 (49/ 148 50 146 (51 49 Work Top Exploded View saw them to shape. Clean up the saw cuts with a drum sander and drill the stopped holes on their insides for the handle. The work top is surrounded by the hardwood frame and held securely by glue blocks (pieces 51) and screws, as shown in the Exploded View above. Frame Assembly The white oak frame is held together with screwed butt joints. Temporarily clamp the frame elements together, then counter-bore and predrill for the large screws. You'll find all the locations on the Pinup Shop Drawings. While you have the frame clamped, dry-fit it to the carcass. A half inch of the face frame's top rail should be peeking out below the bottom of the shaped sides. When everything fits, glue and screw the top frame together, trapping the handle as you do. Plug the screw holes as you did earlier and make sure the handle remains free to turn. Place the frame on top of the carcass, locating it as shown on the Pinup Shop Drawings. Then glue and screw it in place, driving the screws from the inside of the cabinet into the frame. Final Details While you won't be moving this station around too much, it's always nice to be able to rearrange the workshop to accommodate new tools or big projects. Have a friend help you lift the project onto a couple of sawhorses, then bolt a pair of swivel casters (pieces 52) to one end of the bottom, at the locations shown on the Pinup Shop Drawings. Bolt a matching foot on the other end: this is a simple hollow box made up of two sides, a top and two ends (pieces 53, 54 and 55). Butt joint, glue and clamp the foot Winter 2004 31 |