Woodworker's Journal 2006-30-2, страница 16

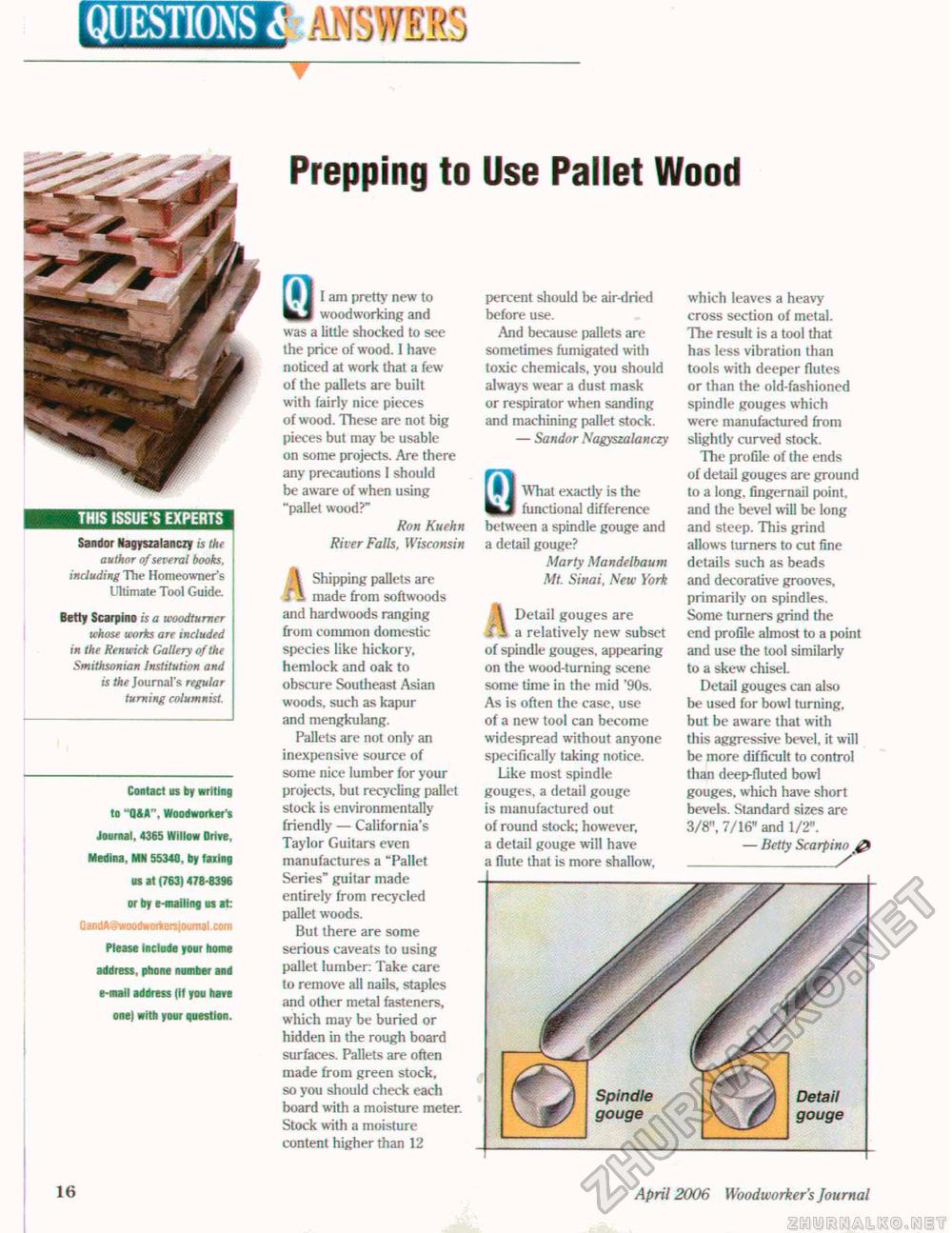

QUESTIONS £ ci im?nc r? r' Kvvj Prepping to Use Pallet Wood THIS ISSUE'S EXPERTS Sandor Hagysialanczy is ike author of several books, including The Homeowner's Ultimate Tool Guide. Betty Scarpino is a woodturner whose works are included in the Ren wick Gallery of the Smithsonian Institution and is the Journal's regular turning columnist Contact us by writing to UM", Woodworker's Journal, 4365 Willow Drive, Medina, MK 55340, by fating us at (763) 478-8396 or by e-mailing us at: QandA^woodwnrlierajounial.coni Please Include your home address, phone number and e-mail address (if you have one) with your question. HI am pretty new to woodworking and was a little shocked to see the price of wood. I have noticed at work that a few of the pallets are built with fairly nice pieces of wood. These are not big pieces but may be usable on some projects. Are there any precautions I should be aware of when using "pallet wood?" Ron Kuehn River Falls, Wisconsin \ Shipping pallets are J i made from softwoods and hardwoods ranging from common domestic species like hickory, hemlock and oak to obscure Southeast Asian woods, such as kapur and mengkulang. Pallets are not only an inexpensive source of some nice lumber for your projects, but recycling pallet stock is environmentally friendly — California's Taylor Guitars even manufactures a "Pallet Series" guitar made entirely from recycled pallet woods. But there are some serious caveats to using pallet lumber: Take care to remove all nails, staples and other metal fasteners, which may be buried or hidden in the rough board surfaces. Pallets are often made from green stock, so you should check each board with a moisture meter. Stock with a moisture content higher than 12 percent should be air-dried before use. And because pallets are sometimes fumigated with toxic chemicals, you should always wear a dust mask or respirator when sanding and machining pallet stock. — Sandor Nagyszalanczy a What exactly is the functional difference between a spindle gouge and a detail gouge? Marty Mandelbaum Mt. Sinai, New York i\ Detail gouges are li a relatively new subset of spindle gouges, appearing on the wood-turning scene some time in the mid '90s. As is often the case, use of a new tool can become widespread without anyone specifically taking notice, Like most spindle gouges, a detail gouge is manufactured out of round stock; however, a detail gouge will have a flute that is more shallow. which leaves a heavy cross section of metal. The result is a tool that has less vibration than tools with deeper flutes or than the old-fashioned spindle gouges which were manufactured from slightly curved stock. The profile of the ends of detail gouges are ground to a long, fingernail point, and the bevel will be long and steep. This grind allows turners to cut fine details such as beads and decorative grooves, primarily on spindles. Some turners grind the end profile almost to a point and use the tool similarly to a skew chisel. Detail gouges can also be used for bowl turning, but be aware that with this aggressive bevel, it will be more difficult to control than deep-fluted bowl gouges, which have short bevels. Standard sizes are 3/8", 7/16" and 1/2". — Betty Scarpino 16 April 2006 Woodworker's Journal |