Woodworker's Journal 2006-30-5, страница 49

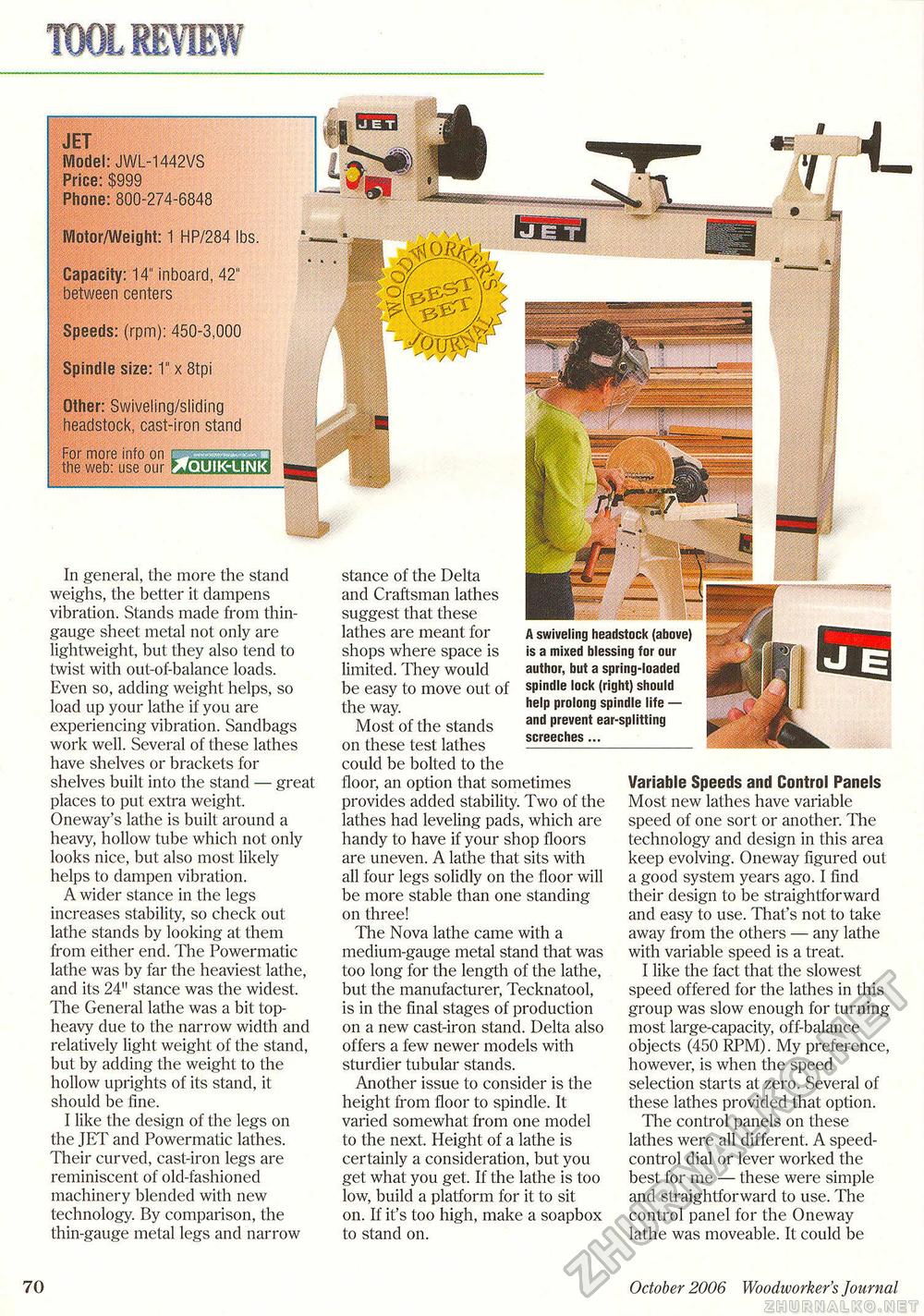

1 mmmttUUBffl JETModel: JWL-1442VS Price: $999 Phone: 800-274-6848 Motor/Weight: 1 HP/284 lbs. Capacity: 14" inboard, 42" between centers Speeds: (rpm): 450-3,000 Spindle size: 1" x 8tpi Other: Swiveling/sliding headstock, cast-iron stand For more info on rp the web: use our zA In general, the more the stand weighs, the better it dampens vibration. Stands made from thin-gauge sheet metal not only are lightweight, but they also tend to twist with out-of-balance loads. Even so, adding weight helps, so load up your lathe if you are experiencing vibration. Sandbags work well. Several of these lathes have shelves or brackets for shelves built into the stand — great places to put extra weight. Oneway's lathe is built around a heavy, hollow tube which not only looks nice, but also most likely helps to dampen vibration. A wider stance in the legs increases stability, so check out lathe stands by looking at them from either end. The Powermatic lathe was by far the heaviest lathe, and its 24" stance was the widest. The General lathe was a bit top-heavy due to the narrow width and relatively light weight of the stand, but by adding the weight to the hollow uprights of its stand, it should be fine. I like the design of the legs on the JET and Powermatic lathes. Their curved, cast-iron legs are reminiscent of old-fashioned machinery blended with new technology. By comparison, the thin-gauge metal legs and narrow stance of the Delta and Craftsman lathes suggest that these lathes are meant for shops where space is limited. They would be easy to move out of the way. Most of the stands on these test lathes could be bolted to the floor, an option that sometimes provides added stability. Two of the lathes had leveling pads, which are handy to have if your shop floors are uneven. A lathe that sits with all four legs solidly on the floor will be more stable than one standing on three! The Nova lathe came with a medium-gauge metal stand that was too long for the length of the lathe, but the manufacturer, Tecknatool, is in the final stages of production on a new cast-iron stand. Delta also offers a few newer models with sturdier tubular stands. Another issue to consider is the height from floor to spindle. It varied somewhat from one model to the next. Height of a lathe is certainly a consideration, but you get what, you get. If the lathe is too low, build a platform for it to sit on. If it's too high, make a soapbox to stand on. A swiveling headstock (above) is a mixed blessing for our author, but a spring-loaded spindle lock (right) should help prolong spindle life — and prevent ear-splitting screeches... Variable Speeds and Control Panels Most new lathes have variable speed of one sort or another. The technology and design in this area keep evolving. Oneway figured out a good system years ago. I find their design to be straightforward and easy to use. That's not to take away from the others — any lathe with variable speed is a treat. I like the fact that the slowest speed offered for the lathes in this group was slow enough for turning most large-capacity, off-balance objects (450 RPM). My preference, however, is when the speed selection starts at zero. Several of these lathes provided that option. The control panels on these lathes were all different. A speed-control dial or lever worked the best for me — these were simple and straightforward to use. The control panel for the Oneway lathe was moveable. It could be 70 October 2006 Woodworker's Journal |