Woodworker's Journal 2006-30-5, страница 47

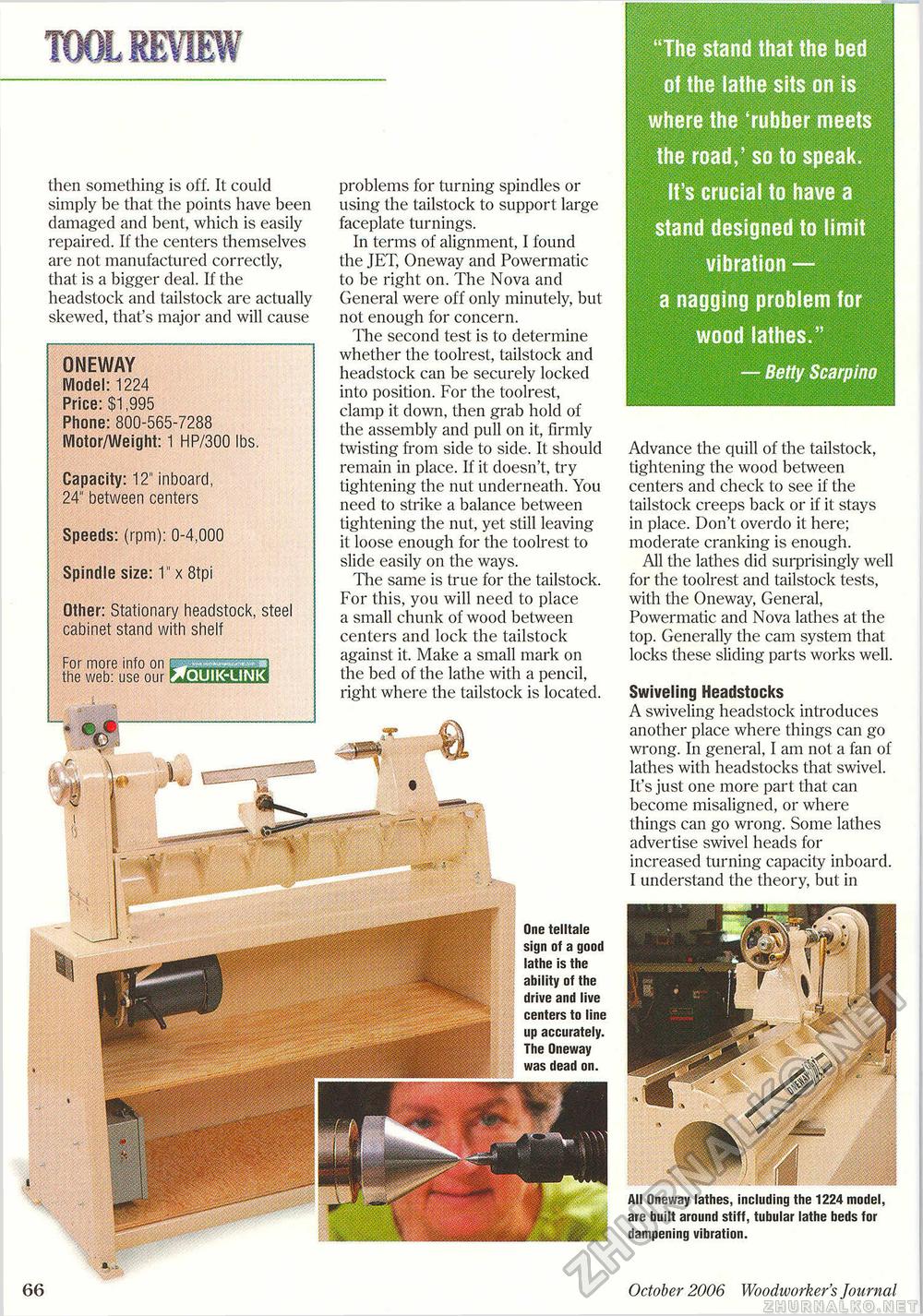

"The stand that the bed of the lathe sits on is where the 'rubber meets the road,' so to speak. It's crucial to have a stand designed to limit vibration — a nagging problem for wood lathes." — Betty Scarpino Advance the quill of the tailstock, tightening the wood between centers and check to see if the tailstock creeps back or if it stays in place. Don't overdo it here; moderate cranking is enough. All the lathes did surprisingly well for the toolrest and tailstock tests, with the Oneway, General, Powermatic and Nova lathes at the top. Generally the cam system that locks these sliding parts works well. Swiveling Headstocks A swiveling headstock introduces another place where things can go wrong. In general, I am not a fan of lathes with headstocks that swivel. It's just one more part that can become misaligned, or where things can go wrong. Some lathes advertise swivel heads for increased turning capacity inboard. I understand the theory, but in All Oneway lathes, including the 1224 model, are built around stiff, tubular lathe beds for dampening vibration. 47 October 2006 Woodivorker's Journal One telltale sign of a good lathe is the ability of the drive and live centers to line up accurately. The Oneway was dead on. problems for turning spindles or using the tailstock to support large faceplate turnings. In terms of alignment, I found the JET, Oneway and Powermatic to be right on. The Nova and General were off only minutely, but not enough for concern. The second test is to determine whether the toolrest, tailstock and headstock can be securely locked into position. For the toolrest, clamp it down, then grab hold of the assembly and pull on it, firmly twisting from side to side. It should remain in place. If it doesn't, try tightening the nut underneath. You need to strike a balance between tightening the nut, yet still leaving it loose enough for the toolrest to slide easily on the ways. The same is true for the tailstock. For this, you will need to place a small chunk of wood between centers and lock the tailstock against it. Make a small mark on the bed of the lathe with a pencil, right where the tailstock is located. then something is off. It could simply be that the points have been damaged and bent, which is easily repaired. If the centers themselves are not manufactured correctly, that is a bigger deal. If the headstock and tailstock are actually skewed, that's major and will cause ONEWAY Model: 1224 Price: $1,995 Phone: 800-565-7288 Motor/Weight: 1 HP/300 lbs. Capacity: 12" inboard, 24" between centers Speeds: (rpm): 0-4,000 Spindle size: 1" x 8tpi Other: Stationary headstock, steel cabinet stand with shelf |