Woodworker's Journal 2006-30-5, страница 44

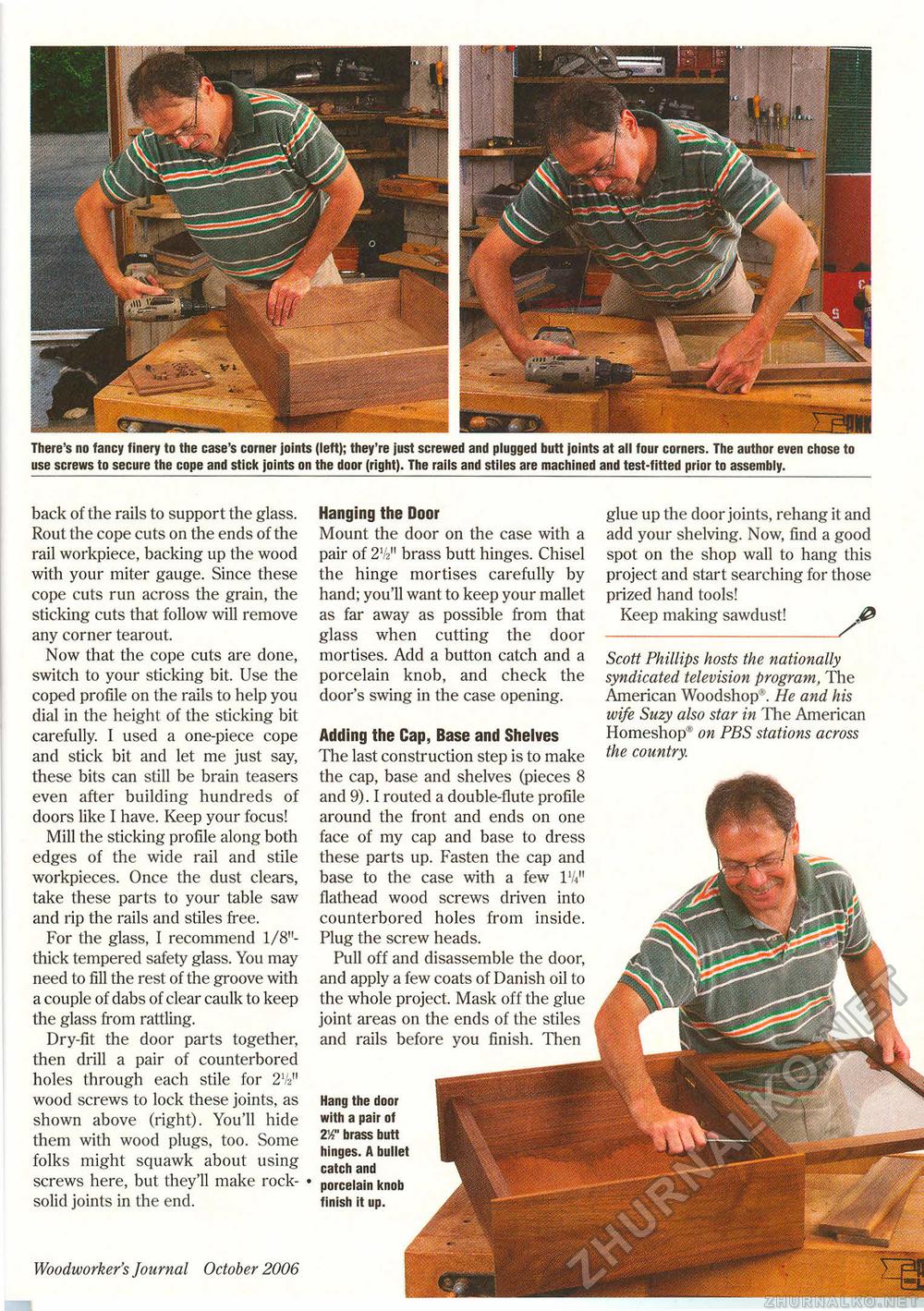

There's no fancy finery to the case's corner joints (left); they're just screwed and plugged butt joints at all four corners. The author even chose to use screws to secure the cope and stick joints on the door (right). The rails and stiles are machined and test-fitted prior to assembly. back of the rails to support the glass. Rout the cope cuts on the ends of the rail workpiece, backing up the wood with your miter gauge. Since these cope cuts run across the grain, the sticking cuts that follow will remove any corner tearout. Now that the cope cuts are done, switch to your sticking bit. Use the coped profile on the rails to help you dial in the height of the sticking bit carefully. I used a one-piece cope and stick bit and let me just say, these bits can still be brain teasers even after building hundreds of doors like I have. Keep your focus! Mill the sticking profile along both edges of the wide rail and stile workpieces. Once the dust clears, take these parts to your table saw and rip the rails and stiles free. For the glass, I recommend 1/8"-thick tempered safety glass. You may need to fill the rest of the groove with a couple of dabs of clear caulk to keep the glass from rattling. Dry-fit the door parts together, then drill a pair of counterbored holes through each stile for 2V2" wood screws to lock these joints, as shown above (right). You'll hide them with wood plugs, too. Some folks might squawk about using screws here, but they'll make rock- • solid joints in the end. Woodworker's Journal October 2006 44 Hang the door with a pair of 2W brass butt hinges. A bullet catch and porcelain knob finish it up. Hanging the Door Mount the door on the case with a pair of 2lkn brass butt hinges. Chisel the hinge mortises carefully by hand; you'll want to keep your mallet as far away as possible from that glass when cutting the door mortises. Add a button catch and a porcelain knob, and check the door's swing in the case opening. Adding the Cap, Base and Shelves The last construction step is to make the cap, base and shelves (pieces 8 and 9). I routed a double-flute profile around the front and ends on one face of my cap and base to dress these parts up. Fasten the cap and base to the case with a few PA" flathead wood screws driven into counterbored holes from inside. Plug the screw heads. Pull off and disassemble the door, and apply a few coats of Danish oil to the whole project. Mask off the glue joint areas on the ends of the stiles and rails before you finish. Then glue up the door joints, rehang it and add your shelving. Now, find a good spot on the shop wall to hang this project and start searching for those prized hand tools! Keep making sawdust! Scott Phillips hosts the nationally syndicated television program, The American Woodshop". He and his wife Suzy also star in The American Homeshop® on PBS stations across the country. |