Woodworker's Journal 2006-30-5, страница 56

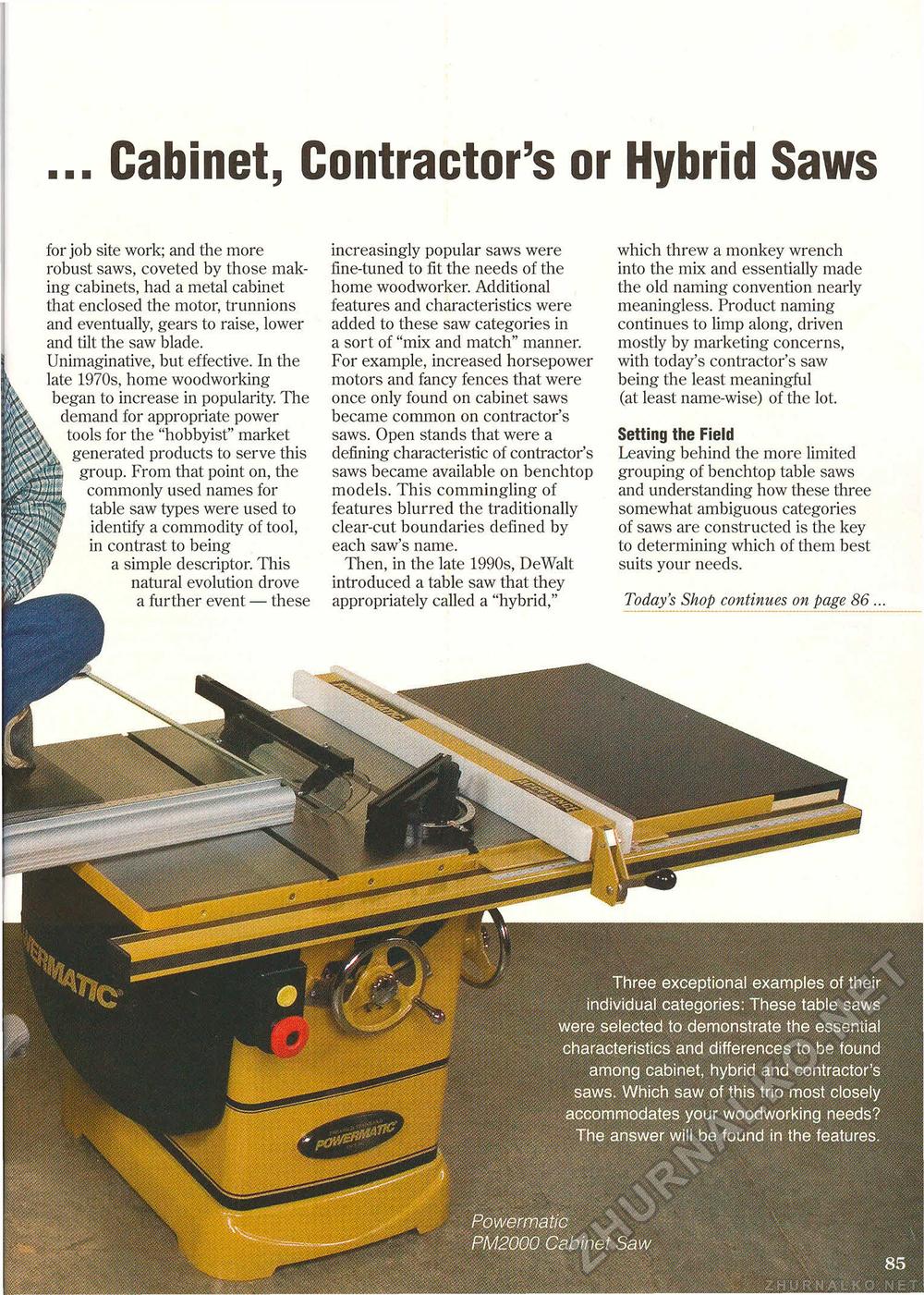

Cabinet, Contractor's or Hybrid Saws for job site work; and the more robust saws, coveted by those making cabinets, had a metal cabinet that enclosed the motor, trunnions and eventually, gears to raise, lower and tilt the saw blade. Unimaginative, but effective. In the late 1970s, home woodworking began to increase in popularity. The demand for appropriate power tools for the "hobbyist" market generated products to serve this group. From that point on, the commonly used names for table saw types were used to identify a commodity of tool, in contrast to being a simple descriptor. This natural evolution drove a further event — these increasingly popular saws were fine-tuned to fit the needs of the home woodworker. Additional features and characteristics were added to these saw categories in a sort of "mix and match" manner. For example, increased horsepower motors and fancy fences that were once only found on cabinet saws became common on contractor's saws. Open stands that were a defining characteristic of contractor's saws became available on benchtop models. This commingling of features blurred the traditionally clear-cut boundaries defined by each saw's name. Then, in the late 1990s, DeWalt introduced a table saw that they appropriately called a "hybrid," which threw a monkey wrench into the mix and essentially made the old naming convention nearly meaningless. Product naming continues to limp along, driven mostly by marketing concerns, with today's contractor's saw being the least meaningful (at least name-wise) of the lot. Setting the Field Leaving behind the more limited grouping of benchtop table saws and understanding how these three somewhat ambiguous categories of saws are constructed is the key to determining which of them best suits your needs. Today's Shop continues on page 86... |