Woodworker's Journal 2006-30-5, страница 59

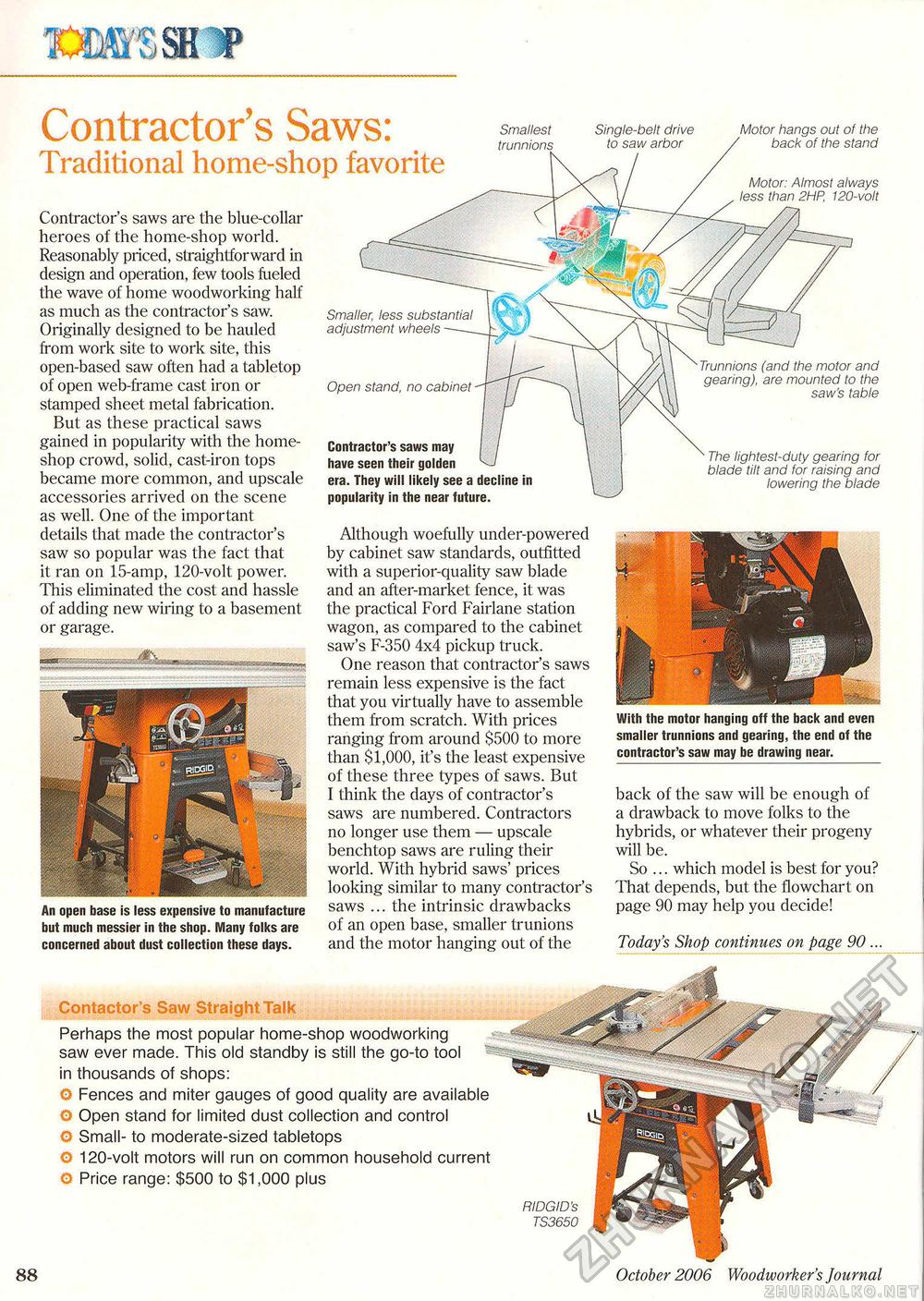

Contactor's Saw Straight Talk Perhaps the most popular home-shop woodworking saw ever made. This old standby is still the go-to tool in thousands of shops: 0 Fences and miter gauges of good quality are available 0 Open stand for limited dust collection and control O Small- to moderate-sized tabletops c 120-volt motors will run on common household current 0 Price range: $500 to $1,000 plus R IDG ID'S TS3650 59 October 2006 Woodivorker's Journal Contractor's Saws: Traditional home-shop favorite Smallest Motor: Almost always less than 2HP, 120-volt Contractor's saws are the blue-collar heroes of the home-shop world. Reasonably priced, straightforward in design and operation, few tools fueled the wave of home woodworking half as much as the contractor's saw. Originally designed to be hauled from work site to work site, this open-based saw often had a tabletop of open web-frame cast iron or stamped sheet metal fabrication. But as these practical saws gained in popularity with the home-shop crowd, solid, cast-iron tops became more common, and upscale accessories arrived on the scene as well. One of the important details that made the contractor's saw so popular was the fact that it ran on 15-amp, 120-volt power. This eliminated the cost and hassle of adding new wiring to a basement or garage. An open base is less expensive to manufacture but much messier in the shop. Many folks are concerned about dust collection these days. Smaller, less substantial adjustment wheels Open stand, no cabinet back of the saw will be enough of a drawback to move folks to the hybrids, or whatever their progeny will be. So ... which model is best for you? That depends, but the flowchart on page 90 may help you decide! Today's Shop continues on page 90 ... Single-belt drive Motor hangs out of the back of the stand Contractor's saws may have seen their golden era. They will likely see a decline in popularity in the near future. Although woefully under-powered by cabinet saw standards, outfitted with a superior-quality saw blade and an after-market fence, it was the practical Ford Fairlane station wagon, as compared to the cabinet saw's F-350 4x4 pickup truck. One reason that contractor's saws remain less expensive is the fact that you virtually have to assemble them from scratch. With prices ranging from around $500 to more than $1,000, it's the least expensive of these three types of saws. But I think the days of contractor's saws are numbered. Contractors no longer use them — upscale benchtop saws are ruling their world. With hybrid saws' prices looking similar to many contractor's saws ... the intrinsic drawbacks of an open base, smaller trunions and the motor hanging out of the With the motor hanging off the back and even smaller trunnions and gearing, the end of the contractor's saw may be drawing near. Trunnions (and the motor and gearing), are mounted to the saw's table The lightest-duty gearing for blade tilt and for raising and lowering the blade |