Woodworker's Journal 2006-30-Winter, страница 60

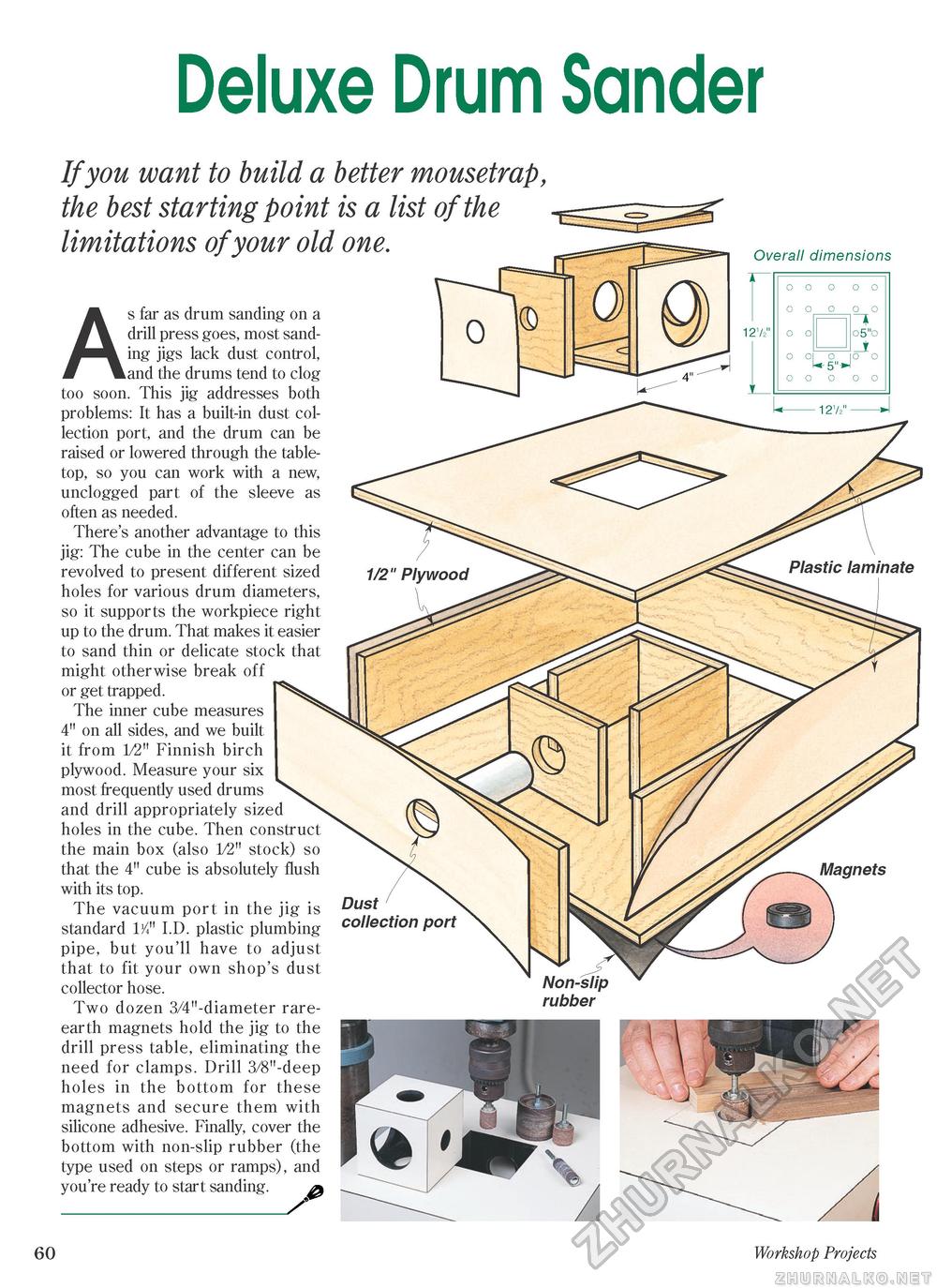

Deluxe Drum SanderIf you want to build a better mousetrap, the best starting point is a list of the limitations of your old one. Overall dimensions As far as drum sanding on a drill press goes, most sanding jigs lack dust control, and the drums tend to clog too soon. This jig addresses both problems: It has a built-in dust collection port, and the drum can be raised or lowered through the table-top, so you can work with a new, unclogged part of the sleeve as often as needed. There's another advantage to this jig: The cube in the center can be revolved to present different sized holes for various drum diameters, so it supports the workpiece right up to the drum. That makes it easier to sand thin or delicate stock that might otherwise break off or get trapped. The inner cube measures 4" on all sides, and we built it from 1/2" Finnish birch plywood. Measure your six most frequentiy used drums and drill appropriately sized holes in the cube. Then construct the main box (also 1/2" stock) so that the 4" cube is absolutely flush with its top. The vacuum port in the jig is standard IK" I.D. plastic plumbing pipe, but you'll have to adjust that to fit your own shop's dust collector hose. Two dozen 3/4"-diameter rare-earth magnets hold the jig to the drill press table, eliminating the need for clamps. Drill 3/8"-deep holes in the bottom for these magnets and secure them with silicone adhesive. Finally, cover the bottom with non-slip rubber (the type used on steps or ramps), and you're ready to start sanding. ^ _/ Dust collection port Non-slip rubber 60 Workshop Projects |