Woodworker's Journal 2008-32-5, страница 58

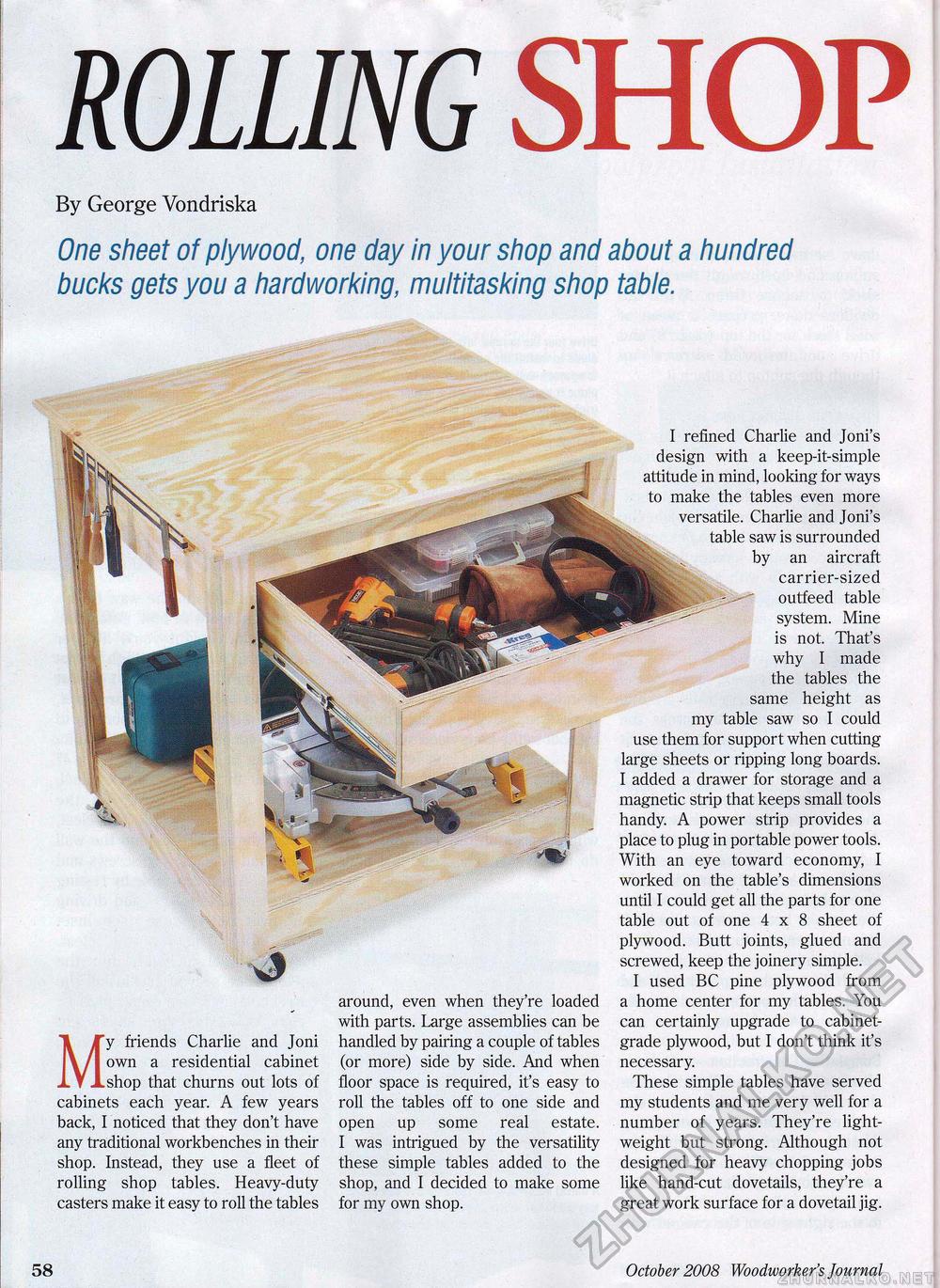

ROLLING SHOPBy George Vondriska One sheet of plywood, one day in your shop and about a hundred bucks gets you a hardworking, multitasking shop table. Ml y friends Charlie and Joni own a residential cabinet .shop that churns out lots of cabinets each year. A few years back, I noticed that they don't have any traditional workbenches in their shop. Instead, they use a fleet of rolling shop tables. Heavy-duty casters make it easy to roll the tables around, even when they're loaded with parts. Large assemblies can be handled by pairing a couple of tables (or more) side by side. And when floor space is required, it's easy to roll the tables off to one side and open up some real estate. I was intrigued by the versatility these simple tables added to the shop, and I decided to make some for my own shop. I refined Charlie and Joni's design with a keep-it-simple attitude in mind, looking for ways to make the tables even more versatile. Charlie and Joni's table saw is surrounded by an aircraft carrier-sized - out feed table system. Mine is not. That's why I made the tables the same height as my table saw so I could use them for support when cutting large sheets or ripping long boards. I added a drawer for storage and a magnetic strip that keeps small tools handy. A power strip provides a place to plug in portable power tools. With an eye toward economy, I worked on the table's dimensions until I could get all the parts for one table out of one 4x8 sheet of plywood. Butt joints, glued and screwed, keep the joinery simple. I used BC pine plywood from a home center for my tables. You can certainly upgrade to cabinet-grade plywood, but I don't think it's necessary. These simple tables have served my students and me very well for a number of years. They're lightweight but strong. Although not designed for heavy chopping jobs like hand-cut dovetails, they're a great work surface for a dovetail jig. 58 October 2008 Woodworker's Journal |