Woodworker's Journal 2008-32-6, страница 59

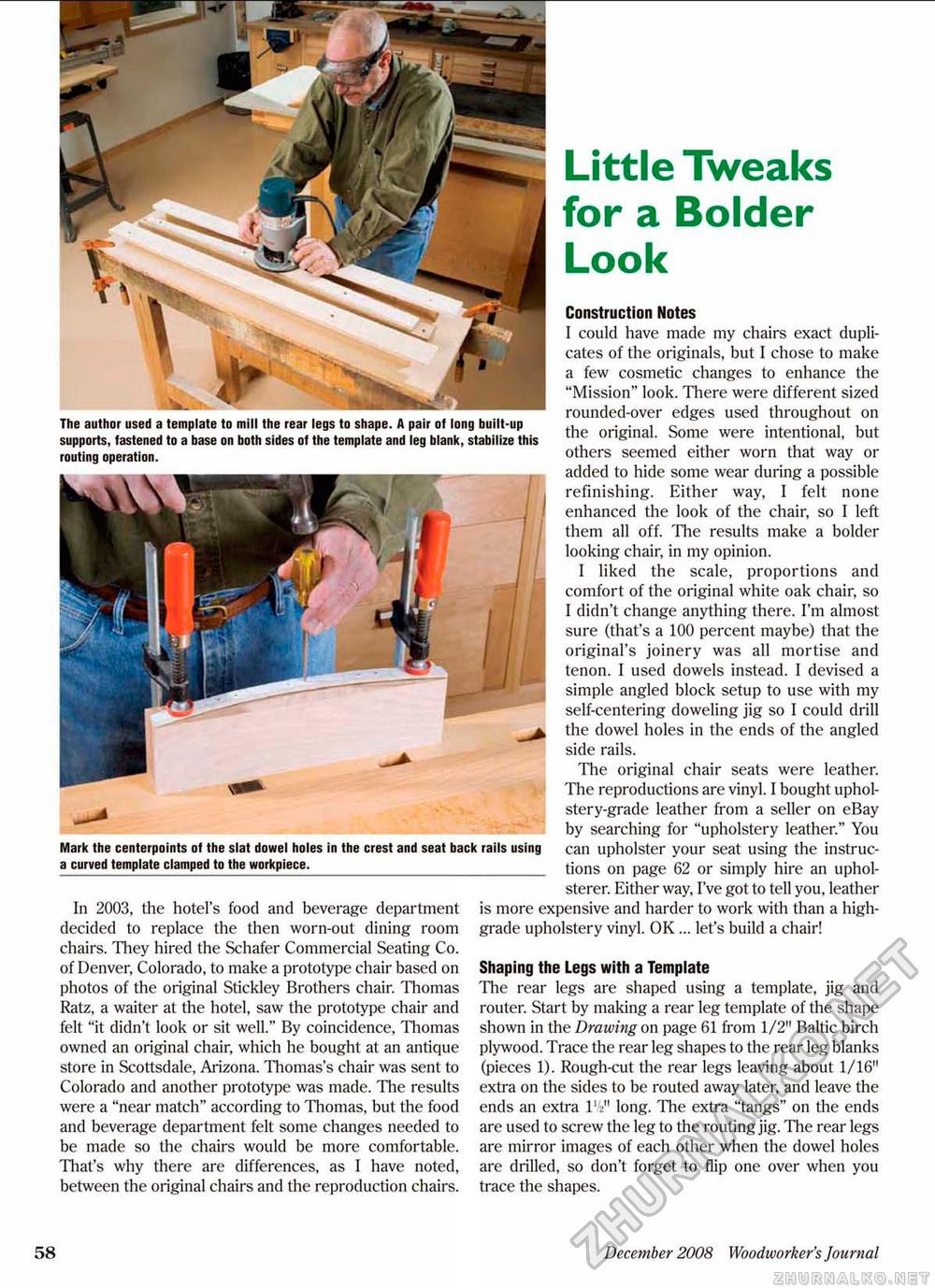

The author used a template to mill the rear legs to shape. A pair ot long built-up supports, fastened to a base on both sides of the template and leg blank, stabilize this routing operation. Little Tweaks for a Bolder Look Construction Notes I coukl have made my chairs exact duplicates of the originals, but I chose to make a few cosmetic changes to enhance the "Mission" look. There were different sized rounded-over edges used throughout on the original. Some were intentional, but others seemed either worn that way or ------ added to hide some wear during a possible refinishing. Either way, I felt none enhanced the look of the chair, so I left them all off. The results make a bolder looking chair, in my opinion. I liked the scale, proportions and comfort of the original white oak chair, so I didn't change anything there. I'm almost sure (that's a 100 percent maybe) that the original's joinery was all mortise and tenon. I used dowels instead. I devised a simple angled block setup to use with my self-centering doweling jig so I could drill the dowel holes in the ends of the angled side rails. The original chair seats were leather. The reproductions are vinyl. I bought upholstery-grade leather from a seller on eBay by searching for "upholstery leather." You Mark the oenterpoints of the slat dowel boles in the crest and seat back rails using can upholster your seat using the instruc-a curved template clamped to the workplace._ tions on page Q2 or simply hire an upholsterer. Either way, I've got to tell you, leather In 2003, the hotel's food and beverage department is more expensive and harder to work with than a higli-decided to replace the then worn-out dining room grade upholstery vinyl. OK... let's build a chair! chairs. They hired the Schafer Commercial Seating Co. of Denver, Colorado, to make a prototype chair based on Shaping the Legs with a Template photos of the original Stickley Brothers chair. Thomas The rear legs are shaped using a template, jig and Ratz, a waiter at the hotel, saw the prototype chair and router. Start by making a rear leg template of the shape felt "it didn't look or sit well." By coincidence, Thomas shown in the Drawing on page 61 from 1/2" Baltic birch owned an original chair, which he bought at an antique plywood. Trace the rear leg shapes to the rear leg blanks store in Scottsdale, Arizona. Thomas's chair was sent to (pieces 1). Rough-cut the rear legs leaving about 1/16" Colorado and another prototype was made. The results extra on the sides to be routed away later, and leave the were a "near match" according to Thomas, but the food ends an extra 1' 2" long. The extra "tangs" on the ends and beverage department felt some changes needed to are used to screw the leg to the routing jig. The rear legs be made so the chairs would be more comfortable, are mirror images of each other when the dowel holes That's why there are differences, as I have noted, are drilled, so don't forget to flip one over when you between the original chairs and the reproduction chairs, trace the shapes. 58 December 2008 Woodworker's Journal |