Woodworker's Journal 2008-32-6, страница 60

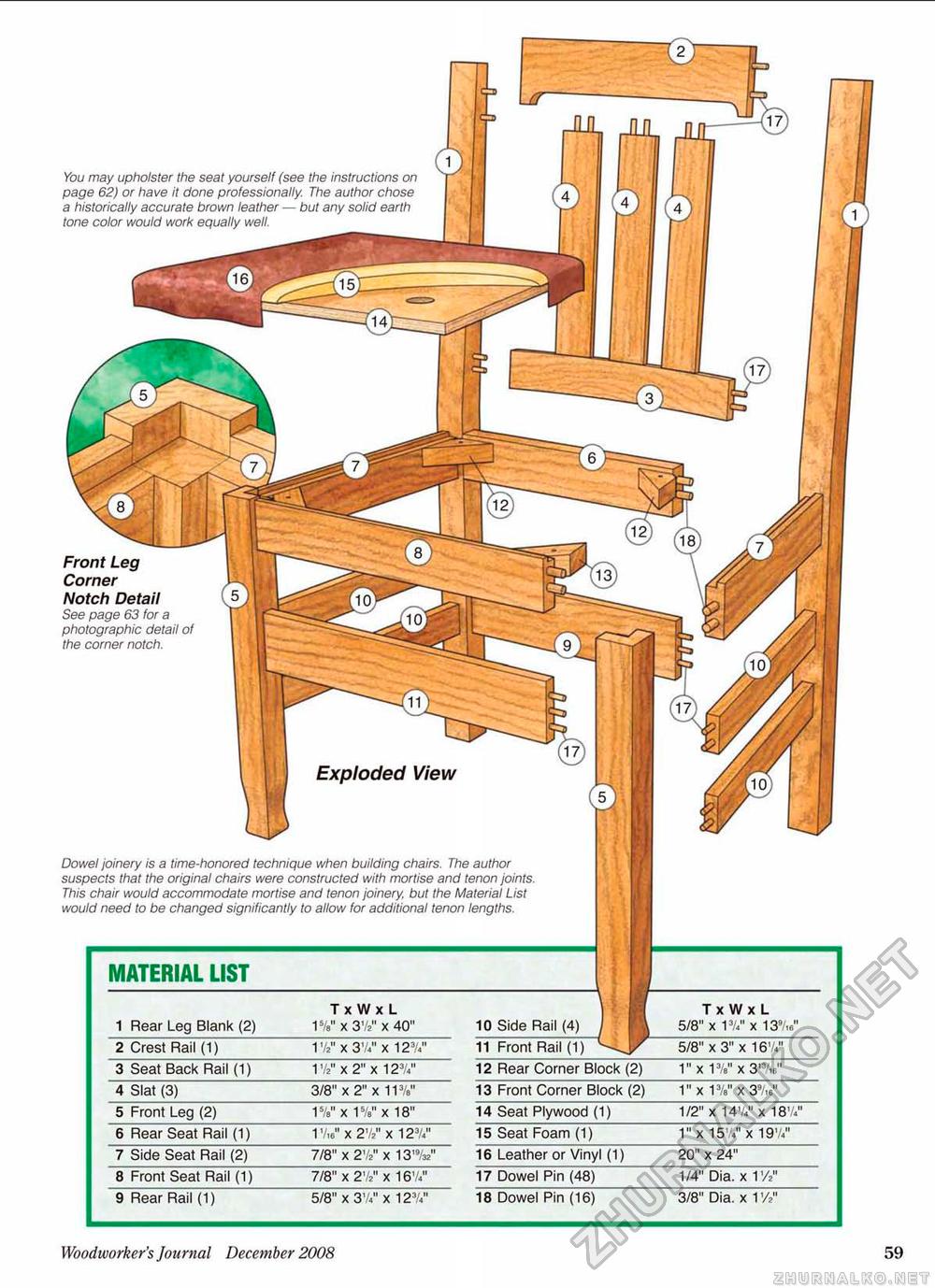

3 Seat Back Rail (1) 1V2" x 2" x 12%" 12 Rear Corner Block (2) 1" x 1%" x 3,3/.e" 4 Slat (3) 3/8" x 2" x 11%" 13 Front Corner Block (2) 1" x 1%" x 39/,< 5 Front Leg (2) 1%" x 1%" x 18" 14 Seat Plywood (1) 1/2" x 14'/." x 18V 6 Rear Seat Rail (1) 17,e" x 2V/ x 12%" 15 Seat Foam (1) 1" x 157.," x 197/ 7 Side Seat Rail (2) 7/8" x 2'/=" x 13,9/32" 16 Leather or Vinyl (1) 20" x 24" 8 Front Seat Rail (1} 7/8" x 2Vi" x 16'/;' 17 Dowel Pin (48) 1/4" Dia. x 1W 9 Rear Rai) (1) 5/8" x 3V x 12%" 18 Dowel Pin (16) 3/8" Dia. x V/" MATERIAL LIST Tx Wx L 1 Rear Leg Blank (2) 1%" x 3V x 40" 10 Side Rail (4) Tx W x L 5/8" x 1 %" x 13%s" 2 Crest Rail (1) 17V x 3V," x 12%" Front Leg Corner Notch Detail See page 63 for a photographic detail of the corner notch. 11 Front Rail (1) 5/8" x 3" x 1674" You may upholster the seat yourself (see the instructions on page 62) or have it done professionally. The author chose a historically accurate brown leather — but any solid earth tone color would work equally well. Dowel joinery is a time-honored technique when building chairs. The author suspects that the original chairs were constructed with mortise and tenon joints. This chair would accommodate mortise and tenon joinery, but the Material List would need to be changed significantly to allow for additional tenon lengths Woodworker's Journal December 2008 59 |