Woodworker's Journal 2009-33-5, страница 26

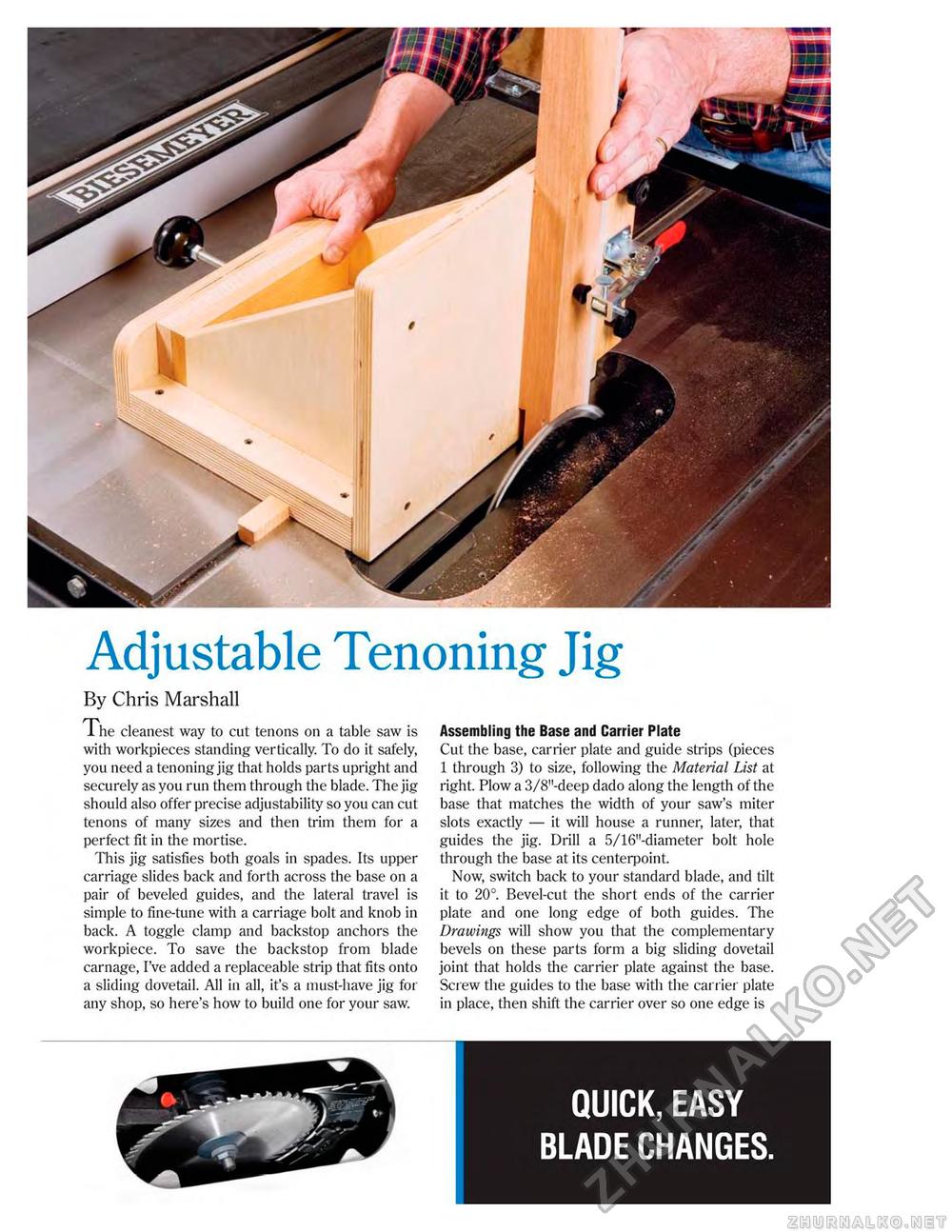

Adjustable Tenoning Jig By Chris Marshall The cleanest way to cut tenons on a table saw is with workpieces standing vertically. To do it safely, you need a tenoning jig that holds parts upright and securely as you run them through the blade. The jig should also offer precise adjustability so you can cut tenons of many sizes and then trim them for a perfect fit in the mortise. This jig satisfies both goals in spades. Its upper carriage slides back and forth across the base on a pair of beveled guides, and the lateral travel is simple to fine-tune with a carriage bolt and knob in back. A toggle clamp and backstop anchors the workpiece. To save the backstop from blade carnage, I've added a replaceable strip that fits onto a sliding dovetail. All in all, it's a must-have jig for any shop, so here's how to build one for your saw. Assembling the Base and Carrier Plate Cut the base, carrier plate and guide strips (pieces 1 through 3) to size, following the Material List at right. Plow a 3/8"-deep dado along the length of the base that matches the width of your saw's miter slots exactly — it will house a runner, later, that guides the jig. Drill a 5/16"-diameter bolt hole through the base at its centerpoint. Now, switch back to your standard blade, and tilt it to 20°. Bevel-cut the short ends of the carrier plate and one long edge of both guides. The Drawings will show you that the complementary bevels on these parts form a big sliding dovetail joint that holds the carrier plate against the base. Screw the guides to the base with the carrier plate in place, then shift the carrier over so one edge is QUICK, EASY BLADE CHANGES. |