Woodworker's Journal 2010-34-2, страница 42

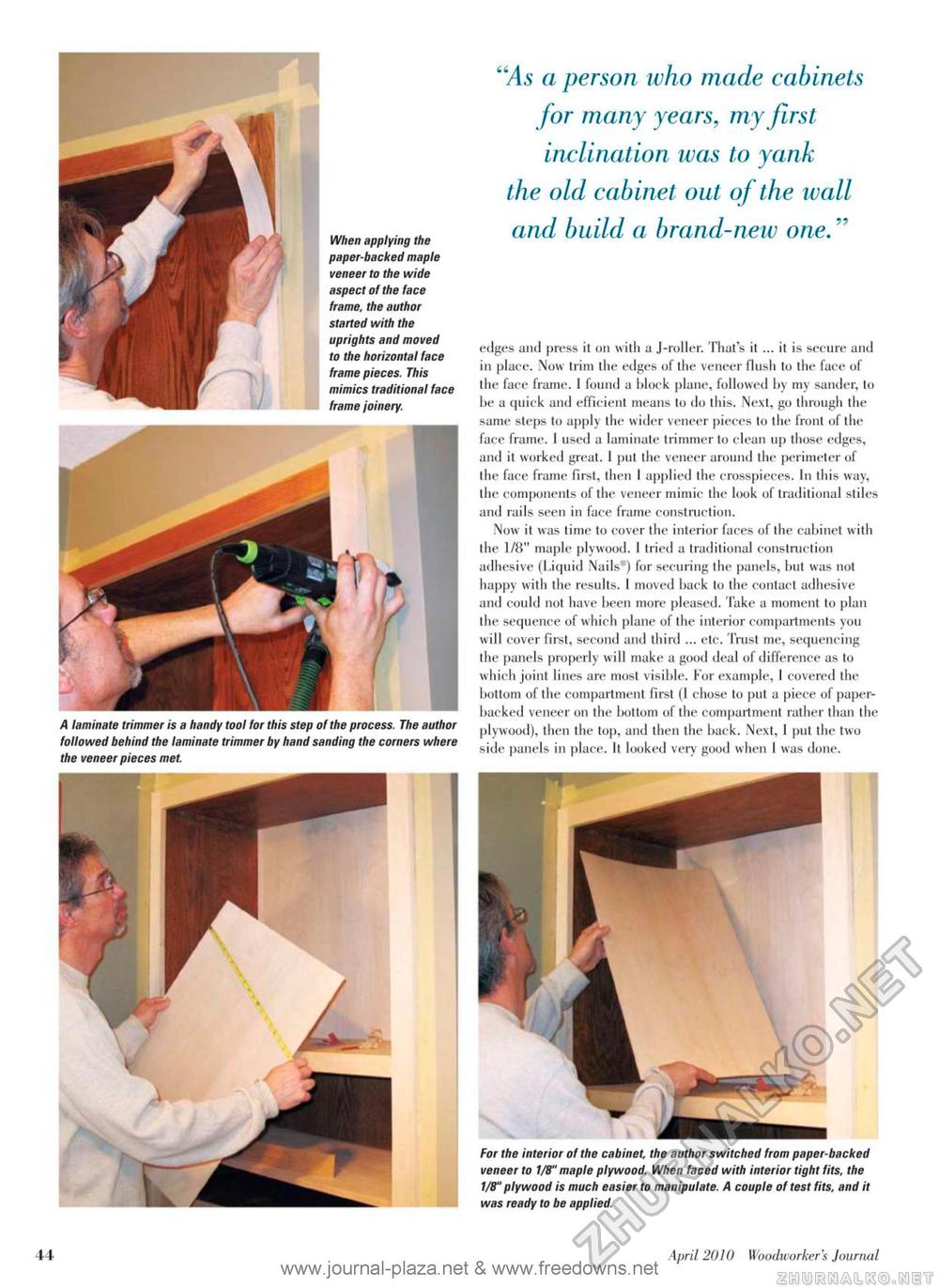

"As a person who made cabinets for many years, my first inclination was to yank the old cabinet out of the wall and build a brand-new one." edges and press it 011 with a J-roller. That's it ... it is secure and in place. Now trim the edges of the veneer flush to the face of the face frame. 1 found a block plane, followed by my sander, to be a quick and efficient means to do this. Next, go through the same steps to apply the wider veneer pieces to the front of the face frame. I used a laminate trimmer to clean up those edges, and it worked great. I put the veneer around the perimeter of the face frame first, then I applied the crosspieces. In this way, the components of the veneer mimic the look of traditional stiles and rails seen in face frame construction. Now it was time to cover the interior faces of the cabinet with the 1/8" maple plywood. I tried a traditional construction adhesive (Liquid Nails®) for securing the panels, but was not happy with the results. 1 moved back to the contact adhesive and could not have been more pleased. Take a moment to plan the sequence of which plane of the interior compartments you will cover first, second and third ... etc. Trust me, sequencing the panels properly will make a good deal of difference as to which joint lines are most visible. For example, I covered the bottom of the compartment first (I chose lo put a piece of paperbacked veneer on the bottom of the compartment rather than the plywood), then the top, and then the back. Next, I put the two side panels in place. It looked very good when 1 was done. When applying the paper-backed maple veneer to the wide aspect of the face frame, the author started with the uprights and moved to the horizontal face frame pieces. This mimics traditional face A laminate trimmer is a handy tool for this step of the process. The author followed behind the laminate trimmer by hand sanding the corners where the veneer pieces met. 42 April 2010 Woodworkers Jourruil www.journal-plaza.net & www.freedowns.net For the interior of the cabinet, the author switched from paper-backed veneer to 1/8" maple plywood. When faced with interior tight fits, the 1/8" plywood is much easier to manipulate. A couple of test fits, and it was ready to be applied. |