Woodworker's Journal fall-2008, страница 62

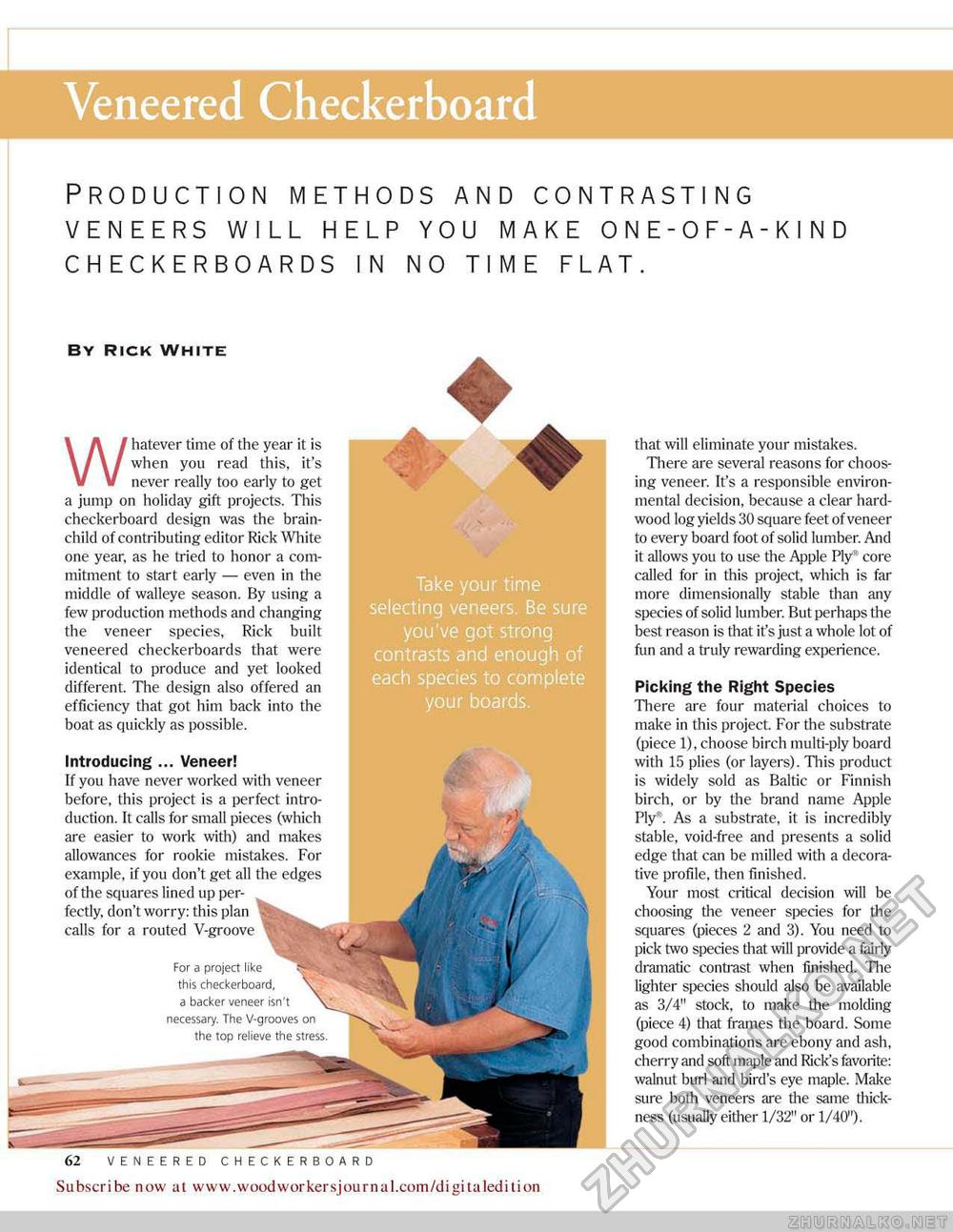

Veneered Checkerboard PRODUCTION METHODS AND CONTRASTING VENEERS WILL HELP YOU MAKE ONE-OF-A-KIND CHECKERBOARDS IN NO TIME FLAT. Take your time selecting veneers. Be sure you've got strong contrasts and enough of each species to complete your boards. By Rick White Whatever time of the year it is when you read this, it's never really too early to get a jump on holiday gift projects. This checkerboard design was the brainchild of contributing editor Rick White one year, as he tried to honor a commitment to start early — even in the middle of walleye season. By using a few production methods and changing the veneer species, Rick built veneered checkerboards that were identical to produce and yet looked different. The design also offered an efficiency that got him back into the boat as quickly as possible. 62 ARtS & CrAFtS STYLE SiDE TABLE Subscribe now at www.woodworkersjournal.com/digitaledition that will eliminate your mistakes. There are several reasons for choosing veneer. It's a responsible environmental decision, because a clear hardwood log yields 30 square feet of veneer to every board foot of solid lumber. And it allows you to use the Apple Ply* core called for in this project, which is far more dimensionally stable than any species of solid lumber. Rut perhaps the best reason is that it's just a whole lot of fun and a truly rewarding experience. Picking the Right Species There are four materia! choices to make in this project. For the substrate (piece 1), choose birch multi-ply board with 15 plies (or layers). This product is widely sold as Baltic or Finnish birch, or by the brand name Apple Ply". As a substrate, it is incredibly stable, void-free and presents a solid edge that can be milled with a decorative profile, then finished. Your most critical decision will be choosing the veneer species for the squares (pieces 2 and 3). You need to pick two species that will provide a fairly dramatic contrast when finished. The lighter species should also be available as 3/4" stock, to make the molding (piece 4) that frames the board. Some good combinations are ebony and ash, cherry and soft maple and Rick's favorite: walnut burl and bird's eye maple. Make sure both veneers are the same thickness (usually either 1/32" or 1/40"). Introducing ... Veneer! If you have never worked with veneer before, this project is a perfect introduction. It calls for small pieces (which are easier to work with) and makes allowances for rookie mistakes. For example, if you don't get all the edges of the squares lined up perfectly, don't worry: this plan calls for a routed V-groove For a project like this checkerboard, a backer veneer isn't necessary. The V-grooves on the top relieve the stress |