Woodworker's Journal fall-2008, страница 71

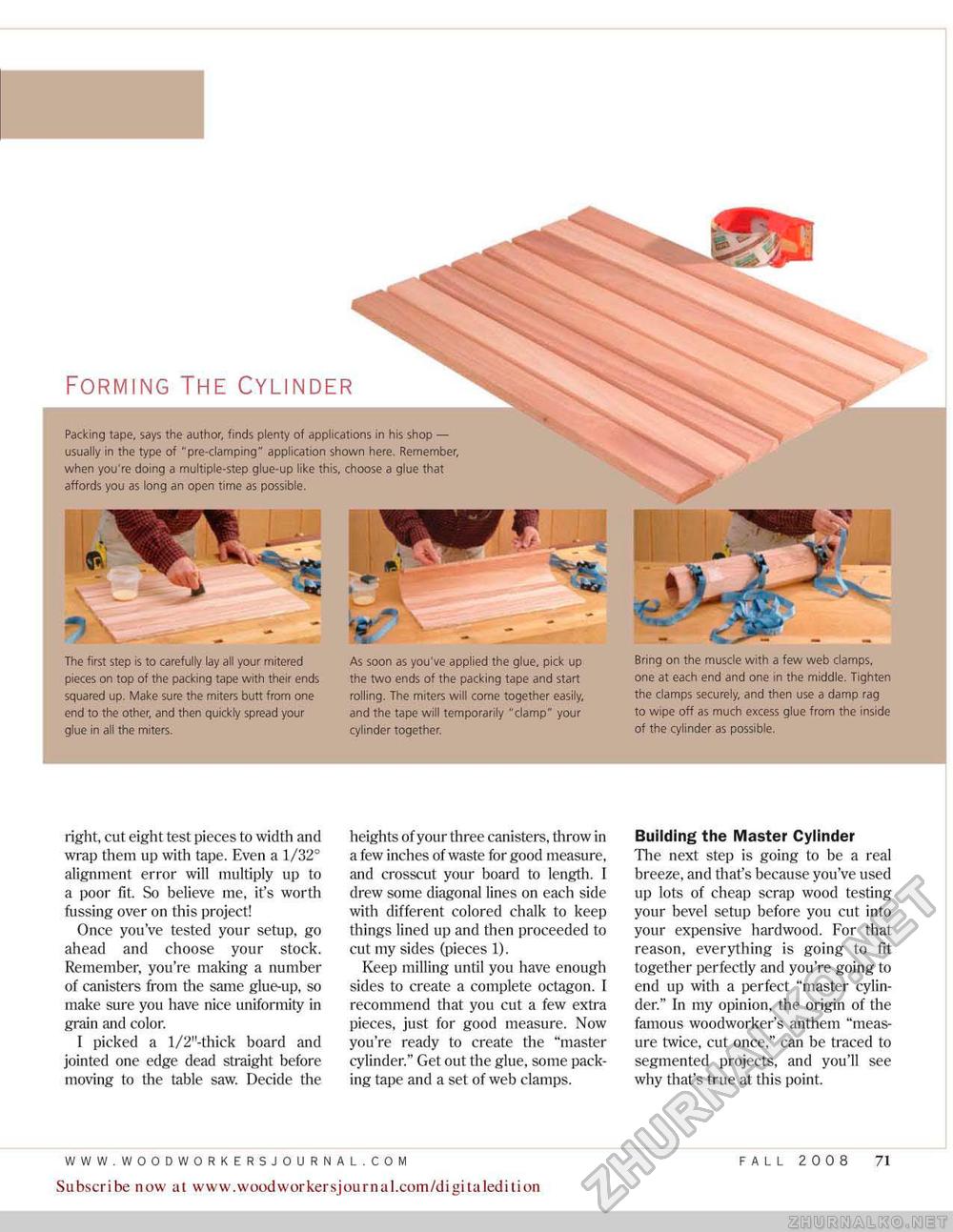

Forming The Cylinder Packing tape, says the author, finds plenty of applications in his shop — usually in the type of "pre-clamping" application shown here. Remember, when you're doing a multiple-step glue-up like this, choose a glue that affords you as long an open time as possible. Bring on the muscle with a few web clamps, one at each end and one in the middle. Tighten the clamps securely, and then use a damp rag to wipe off as much excess glue from the inside of the cylinder as possible. The first step is to carefully lay all your mitered pieces on top of the packing tape with their ends squared up. Make sure the miters butt from one end to the other, and then quickly spread your glue in all the miters. As soon as you've applied the glue, pick up the two ends of the packing tape and start rolling. The miters will come together easily, and the tape wiil temporarily "clamp" your cylinder together. right, cut eight test pieces to width and wrap them up with tape. Even a 1/32° alignment error will multiply up to a poor fit. So believe me, it's worth fussing over on this project! Once you've tested your setup, go ahead and choose your stock. Remember, you're making a number of canisters from the same glue-up, so make sure you have nice uniformity in grain and color. I picked a l/2"-thick board and jointed one edge dead straight before moving to the table saw. Decide the heights of your three canisters, throw in a few inches of waste for good measure, and crosscut your board to length. I drew some diagonal lines on each side with different colored chalk to keep things lined up and then proceeded to cut my sides {pieces 1). Keep milling until you have enough sides to create a complete octagon. I recommend that you cut a few extra pieces, just for good measure. Now you're ready to create the "master cylinder." Get out the glue, some packing tape and a set of web clamps. Building the Master Cylinder The next step is going to be a real breeze, and that's because you've used up lots of cheap scrap wood testing your bevel setup before you cut into your expensive hardwood. For that reason, everything is going to fit together perfectly and you're going to end up with a perfect "master cylinder." In my opinion, the origin of the famous woodworker's anthem "measure twice, cut once," can be traced to segmented projects, and you'll see why that's true at this point. Subscribe now at www.woodwoirkersjournal.com/digitaledition FALL 2008 71 |