Woodworker's Journal Summer-2008, страница 46

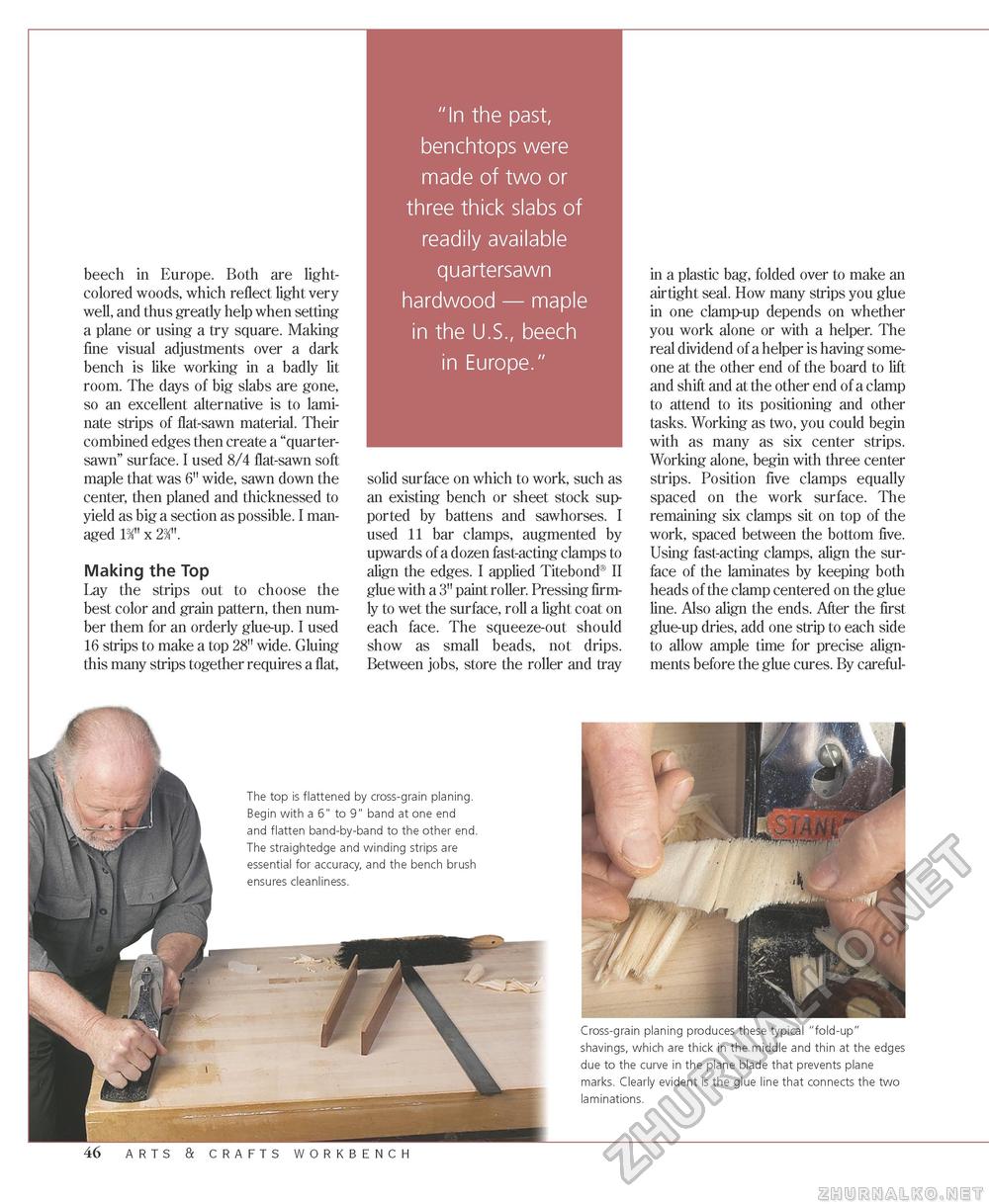

beech in Europe. Both are light-colored woods, which reflect light very well, and thus greatly help when setting a plane or using a try square. Making fine visual adjustments over a dark bench is like working in a badly lit room. The days of big slabs are gone, so an excellent alternative is to laminate strips of flat-sawn material. Their combined edges then create a "quarter- in a plastic bag, folded over to make an airtight seal. How many strips you glue in one clamp-up depends on whether you work alone or with a helper. The real dividend of a helper is having someone at the other end of the board to lift and shift and at the other end of a clamp to attend to its positioning and other tasks. Working as two, you could begin with as many as six center strips. sawn" surface. I used 8/4 flat-sawn soft maple that was 6" wide, sawn down the center, then planed and thicknessed to yield as big a section as possible. I managed 134" x 234". Making the Top Lay the strips out to choose the best color and grain pattern, then number them for an orderly glue-up. I used 16 strips to make a top 28" wide. Gluing this many strips together requires a flat, "In the past, benchtops were made of two or three thick slabs of readily available quartersawn hardwood — maple in the U.S., beech in Europe." solid surface on which to work, such as an existing bench or sheet stock supported by battens and sawhorses. I used 11 bar clamps, augmented by upwards of a dozen fast-acting clamps to align the edges. I applied Titebond® II glue with a 3" paint roller. Pressing firmly to wet the surface, roll a light coat on each face. The squeeze-out should show as small beads, not drips. Between jobs, store the roller and tray Working alone, begin with three center strips. Position five clamps equally spaced on the work surface. The remaining six clamps sit on top of the work, spaced between the bottom five. Using fast-acting clamps, align the surface of the laminates by keeping both heads of the clamp centered on the glue line. Also align the ends. After the first glue-up dries, add one strip to each side to allow ample time for precise alignments before the glue cures. By careful- The top is flattened by cross-grain planing. Begin with a 6" to 9" band at one end and flatten band-by-band to the other end. The straightedge and winding strips are essential for accuracy, and the bench brush ensures cleanliness. Cross-grain planing produces these typical "fold-up" shavings, which are thick in the middle and thin at the edges due to the curve in the plane blade that prevents plane marks. Clearly evident is the glue line that connects the two laminations. 46 arts & crafts workbench |