Woodworker's Journal summer-2009, страница 23

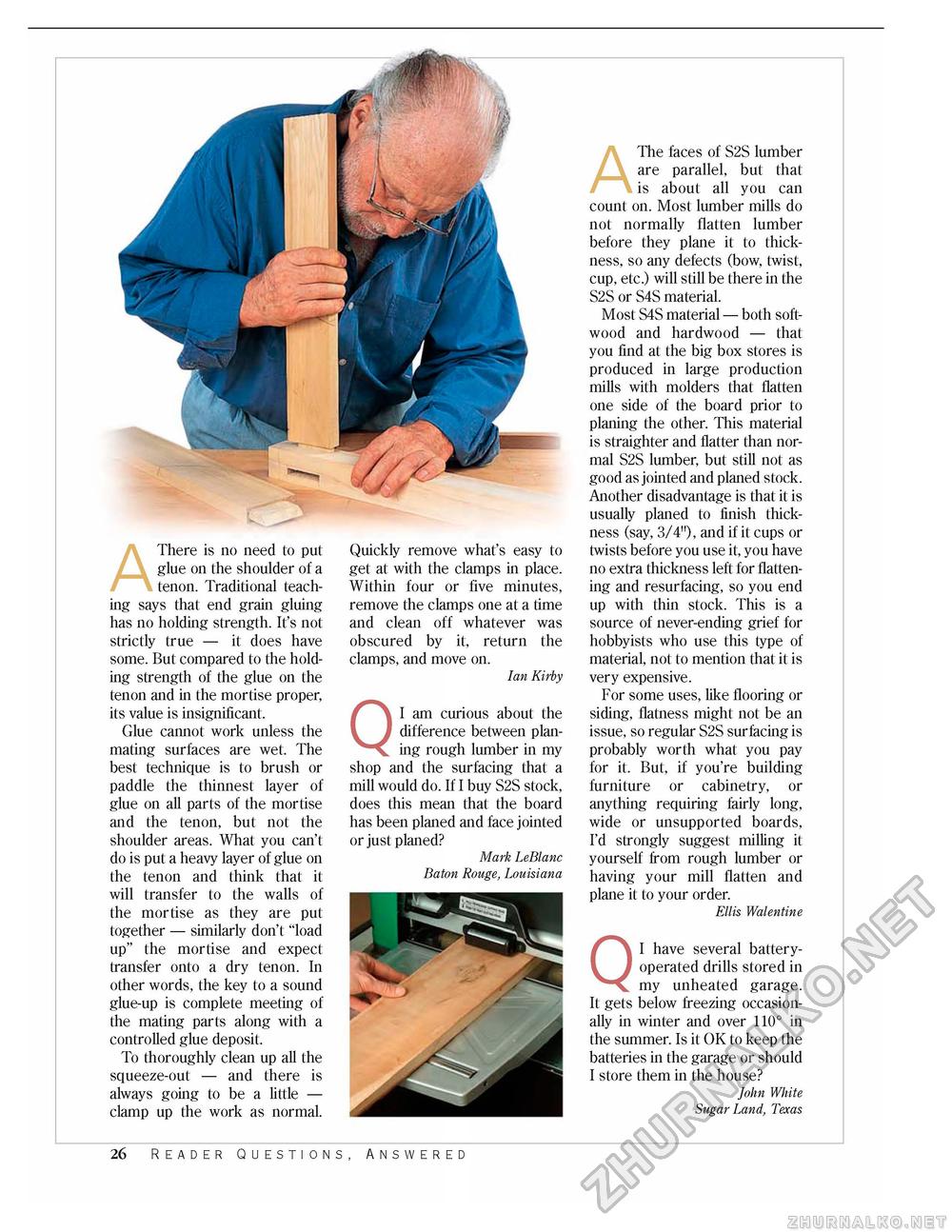

A There is no need to put glue on the shoulder of a tenon. Traditional teaching says that end grain gluing has no holding strength. Its not strictly true — it does have some. But compared to the holding strength of the glue on the tenon and in the mortise proper, its value is insignificant. Glue cannot work unless the mating surfaces are wet. The best technique is to brush or paddle the thinnest layer of glue on all parts of the mortise and the tenon, but not the shoulder areas. What you can't do is put a heavy layer of glue on the tenon and think that it will transfer to the walls of the mortise as they are put together — similarly don't "load up" the mortise and expect transfer onto a dry tenon. In other words, the key to a sound glue-up is complete meeting of the mating parts along with a controlled glue deposit. To thoroughly clean up all the squeeze-out — and there is always going to be a little — clamp up the work as normal. Quickly remove what's easy to get at with the clamps in place. Within four or five minutes, remove the clamps one at a time and clean off whatever was obscured by it, return the clamps, and move on. Ian Kirby QI am curious about the difference between planing rough lumber in my shop and the surfacing that a mill would do. If I buy S2S stock, does this mean that the board has been planed and face jointed or just planed? Mark LeBlanc Baton Rouge, Louisiana A The faces of S2S lumber are parallel, but that is about all you can count on. Most lumber mills do not normally flatten lumber before they plane it to thickness, so any defects (bow, twist, cup, etc.) will still be there in the S2S or S4S material. Most S4S material — both softwood and hardwood — that you find at the big box stores is produced in large production mills with molders that flatten one side of the board prior to planing the other. 'Hiis material is straighter and flatter than normal S2S lumber, but still not as good as jointed and planed stock. Another disadvantage is that it is usually planed to finish thickness (say, 3/4"), and if it cups or twists before you use it, you have no extra thickness left for flattening and resurfacing, so you end up with thin stock. This is a source of never-ending grief for hobbyists who use this type of material, not to mention that it is very expensive. For some uses, like flooring or siding, flatness might not be an issue, so regular S2S surfacing is probably worth what you pay for it. But, if you're building furniture or cabinetry, or anything requiring fairly long, wide or unsupported boards, I'd strongly suggest milling it yourself from rough lumber or having your mill flatten and plane it to your order. Ellis Walentine QI have several battery-operated drills stored in my unheated garage. It gets below freezing occasionally in winter and over 110° in the summer. Is it OK to keep the batteries in the garage or should I store them in the house? John White Sugar Land, Texas 26 reader questions, answered |