Woodworker's Journal summer-2009, страница 29

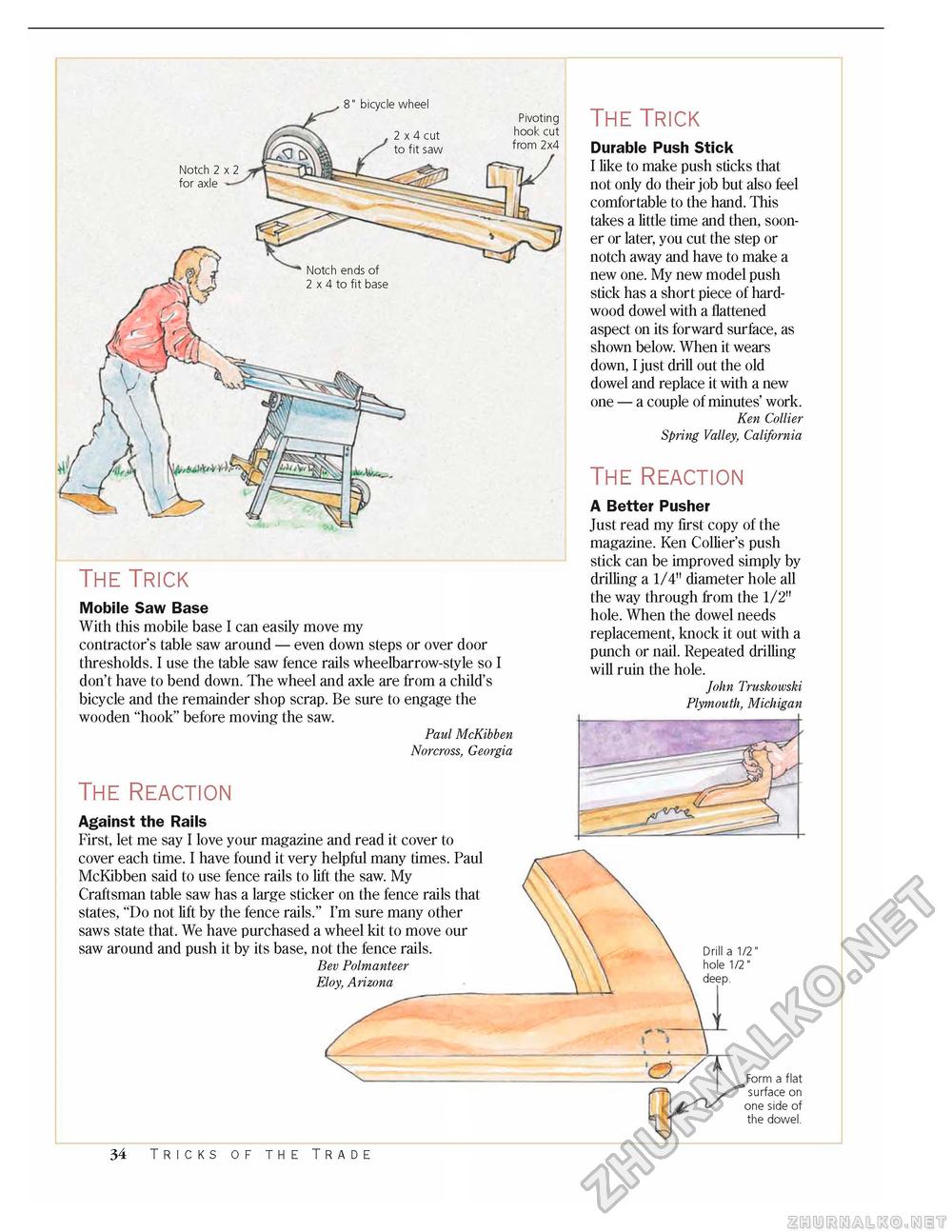

Form a flat surface on 3ne side of the dowel. The Reaction The Trick Durable Push StickI like to make push sticks that not only do their job but also feel comfortable to the hand. This takes a little time and then, sooner or later, you cut the step or notch away and have to make a new one. My new model push stick has a short piece of hardwood dowel with a flattened aspect on its forward surface, as shown below. When it wears down, I just drill out the old dowel and replace it with a new one — a couple of minutes' work. Ken Collier Spring Valley, California The Reaction A Better PusherJust read my first copy of the magazine. Ken Collier's push stick can be improved simply by drilling a 1/4" diameter hole all the way through from the 1/2" hole. When the dowel needs replacement, knock it out with a punch or nail. Repeated drilling will ruin the hole. John Truskowski Plymouth, Michigan Against the Rails First, let me say I love your magazine and read it cover to cover each time. I have found it very helpful many times. Paul McKibben said to use fence rails to lift the saw. My Craftsman table saw has a large sticker on the fence rails that states, "Do not lift by the fence rails." I'm sure many other saws state that. We have purchased a wheel kit to move our saw around and push it by its base, not the fence rails. Bev Polmanteer Eloy, Arizona Drill a 1/2" hole 1/2" The Trick Mobile Saw BaseWith this mobile base I can easily move my contractor's table saw around — even down steps or over door thresholds. I use the table saw fence rails wheelbarrow-style so I don't have to bend down. The wheel and axle are from a child's bicycle and the remainder shop scrap. Be sure to engage the wooden "hook" before moving the saw. Paul McKibben Norcross, Georgia Notch 2 x 2 for axle Notch ends of 2 x 4 to fit base 8" bicycle wheel 2 x 4 cut Pivoting hook cut from 2x4 34 Tricks of the Trade |