Woodworker's Journal summer-2009, страница 31

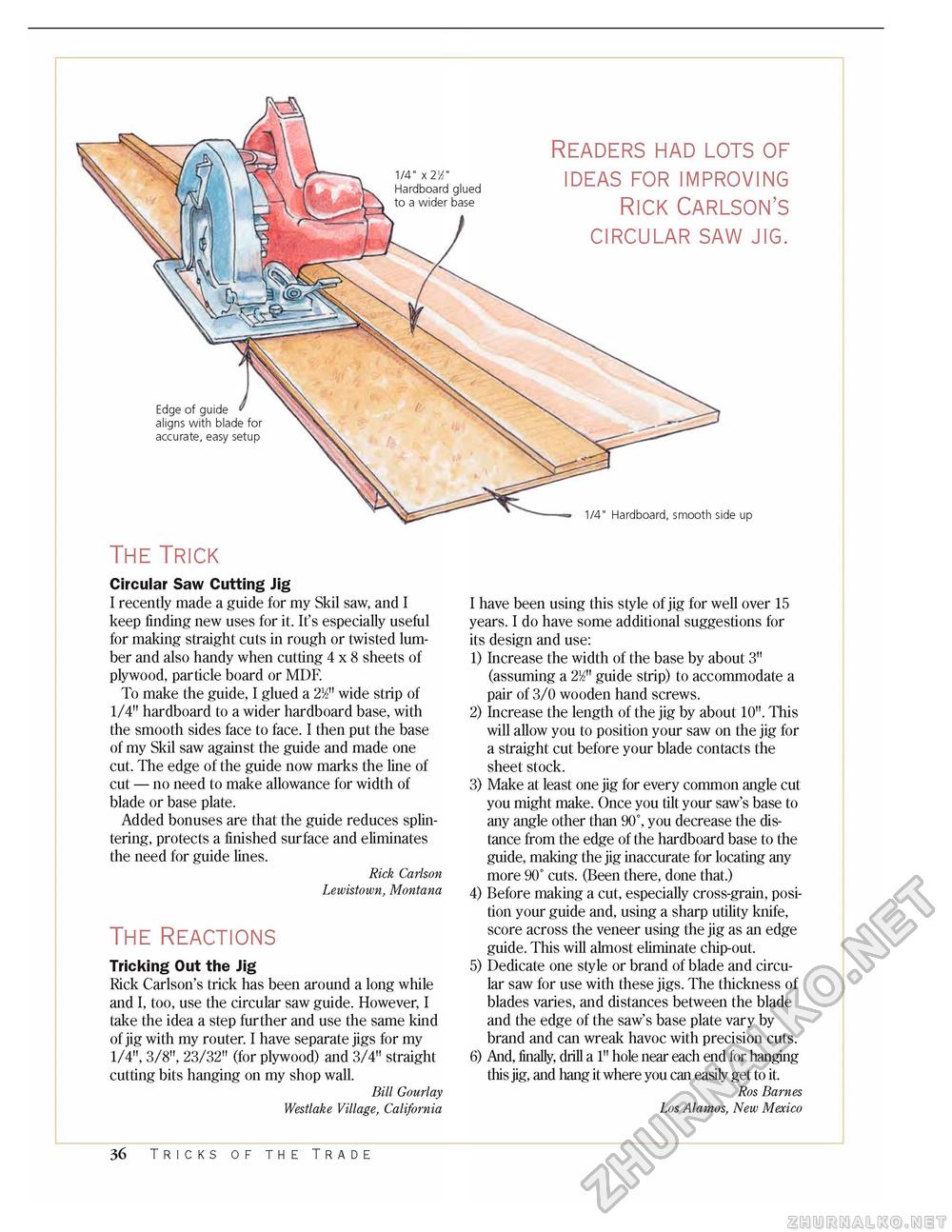

Edge of guide aligns with blade for accurate, easy setup 1/4" Hardboard, smooth side up Readers had lots of circular saw jig. 1/4" x 2~r Hardboard glued to a wider base ideas for improving rick carlson's The Trick Circular Saw Cutting JigI recently made a guide for my Skil saw, and I keep finding new uses for it. It's especially useful for making straight cuts in rough or twisted lumber and also handy when cutting 4x8 sheets of plywood, particle board or MDF. To make the guide, I glued a 2',i" wide strip of 1/4" hardboard to a wider hardboard base, with the smooth sides face to face. I then put the base of my Skil saw against the guide and made one cut. The edge of the guide now marks the line of cut — no need to make allowance for width of blade or base plate. Added bonuses are that the guide reduces splintering, protects a finished surface and eliminates the need for guide lines. Rick Carlson Lewistown, Montana The Reactions Tricking Out the JigRick Carlson's trick has been around a long while and I, too, use the circular saw guide. However, I take the idea a step further and use the same kind of jig with my router. I have separate jigs for my 1/4", 3/8", 23/32" (for plywood) and 3/4" straight cutting bits hanging on my shop wall. Bill Gourlay Westlake Village, California I have been using this style of jig for well over 15 years. I do have some additional suggestions for its design and use: 1) Increase the width of the base by about 3" (assuming a guide strip) to accommodate a pair of 3/0 wooden hand screws. 2) Increase the length of the jig by about 10". This will allow you to position your saw on the jig for a straight cut before your blade contacts the sheet stock. 3) Make at least one jig for every common angle cut you might make. Once you tilt your saw's base to any angle other than 90°, you decrease the distance from the edge of the hardboard base to the guide, making the jig inaccurate for locating any more 90° cuts. (Been there, done that.) 4) Before making a cut, especially cross-grain, position your guide and, using a sharp utility knife, score across the veneer using the jig as an edge guide. This will almost eliminate chip-out. 5) Dedicate one style or brand of blade and circular saw for use with these jigs. The thickness of blades varies, and distances between the blade and the edge of the saw's base plate vary by brand and can wreak havoc with precision cuts. 6) And, finally, drill a 1" hole near each end for hanging this jig, and hang it where you can easily get to it. Ros Barnes Los Alamos, New Mexico 36 Tricks of the Trade |