Woodworker's Journal summer-2009, страница 33

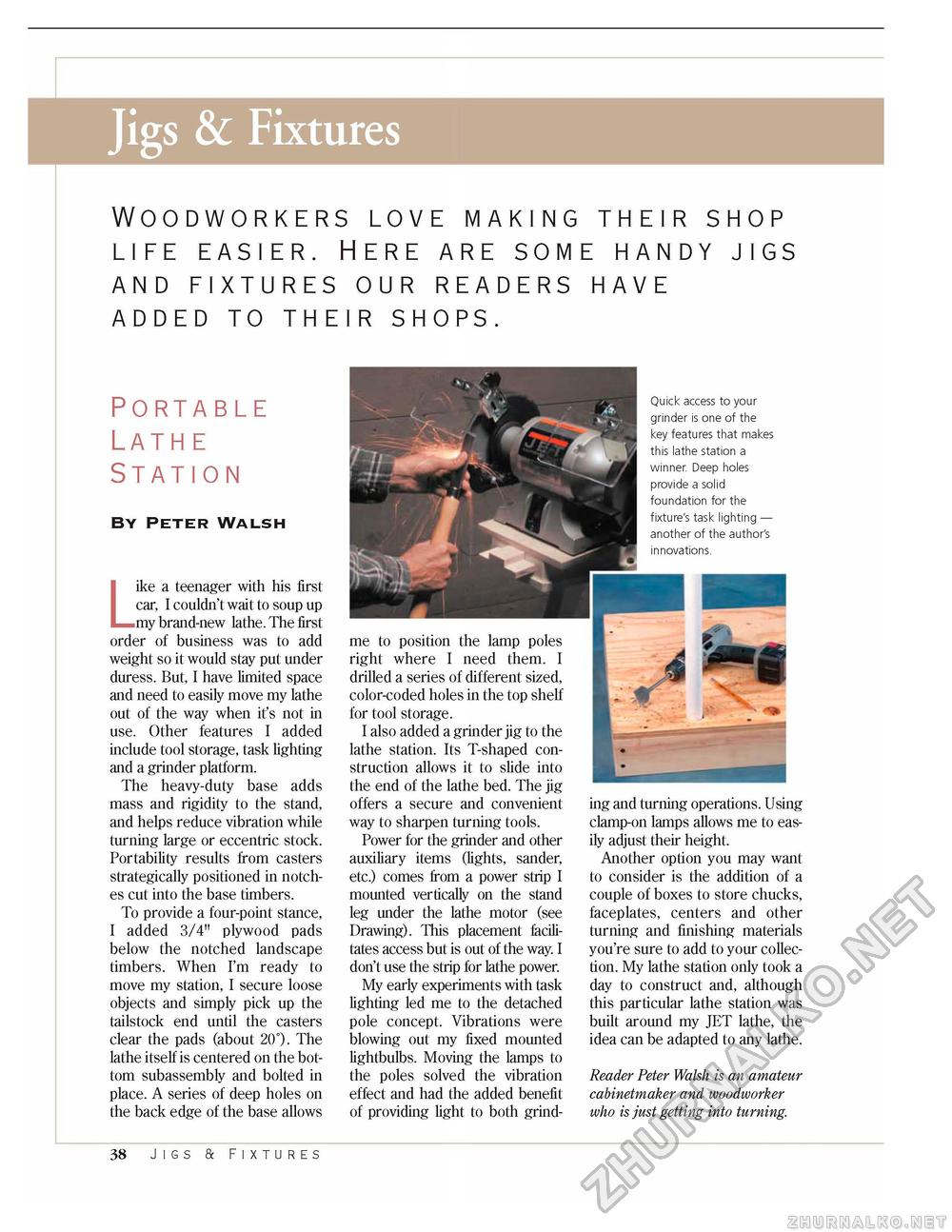

Jigs & FixturesWoodworkers love making their shoplife easier. here are some handy jigs and fixtures our readers have added to their shops.portableLathe StationBy Peter WalshLike a teenager with his first car, I couldn't wait to soup up my brand-new lathe. The first order of business was to add weight so it would stay put under duress. But, I have limited space and need to easily move my lathe out of the way when it's not in use. Other features I added include tool storage, task lighting and a grinder platform. The heavy-duty base adds mass and rigidity to the stand, and helps reduce vibration while turning large or eccentric stock. Portability results from casters strategically positioned in notches cut into the base timbers. To provide a four-point stance, I added 3/4" plywood pads below the notched landscape timbers. When I'm ready to move my station, I secure loose objects and simply pick up the tailstock end until the casters clear the pads (about 20°)- The lathe itself is centered on the bottom subassembly and bolted in place. A series of deep holes on the back edge of the base allows 38 Jigs a Fixtures Quick access to your grinder is one of the key features that makes this lathe station a winner Deep holes provide a solid foundation for the fixture's task lighting — another of the author's innovations. me to position the lamp poles right where I need them. I drilled a series of different sized, color-coded holes in the top shelf for tool storage. I also added a grinder jig to the lathe station. Its T-shaped construction allows it to slide into the end of the lathe bed. The jig offers a secure and convenient way to sharpen turning tools. Power for the grinder and other auxiliary items (lights, sander, etc.) comes from a power strip I mounted vertical^ on the stand leg under the lathe motor (see Drawing). This placement iacili-tates access but is out of the way. I don't use the strip for lathe power. My early experiments with task lighting led me to the detached pole concept. Vibrations were blowing out my fixed mounted lightbulbs. Moving the lamps to the poles solved the vibration effect and had the added benefit of providing light to both grind ing and turning operations. Using clamp-on lamps allows me to easily adjust their height. Another option you may want to consider is the addition of a couple of boxes to store chucks, faceplates, centers and other turning and finishing materials you're sure to add to your collection. My lathe station only took a day to construct and, although this particular lathe station was built around my JET lathe, the idea can be adapted to any lathe. Reader Peter Walsh is an amateur cabinetmaker and woodworker who is just getting into turning. |