Woodworker's Journal summer-2009, страница 36

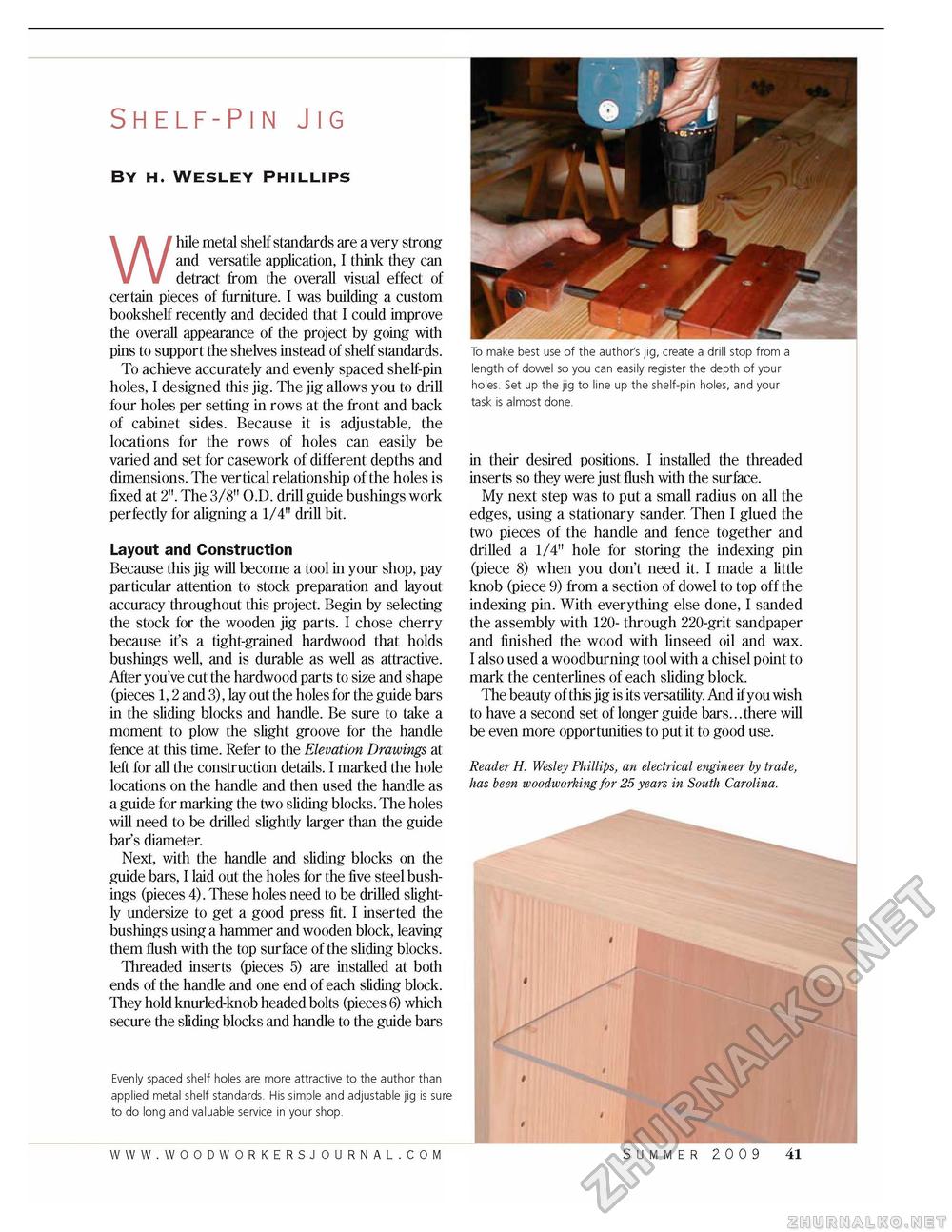

Shelf-Pin JigBy h. Wesley PhillipsWhile metal shelf standards are a very strong and versatile application, I think they can detract from the overall visual effect of certain pieces of furniture. I was building a custom bookshelf recentfy and decided that I could improve the overall appearance of the project by going with pins to support the shelves instead of shelf standards. To achieve accurately and evenly spaced shelf-pin holes, I designed this jig. The jig allows you to drill four holes per setting in rows at the front and back of cabinet sides. Because it is adjustable, the locations for the rows of holes can easily be varied and set for casework of different depths and dimensions. The vertical relationship of the holes is fixed at 2". The 3/8" O.D. drill guide bushings work perfectly for aligning a 1/4" drill bit. Layout and Construction Because this jig will become a tool in your shop, pay particular attention to stock preparation and layout accuracy throughout this project. Begin by selecting the stock for the wooden jig parts. I chose cherry because it's a tight-grained hardwood that holds bushings well, and is durable as well as attractive. After you've cut the hardwood parts to size and shape (pieces 1,2 and 3), lay out the holes for the guide bars in the sliding blocks and handle. Be sure to take a moment to plow the slight groove for the handle fence at this time. Refer to the Elevation Drawings at left for all the construction details. I marked the hole locations on the handle and then used the handle as a guide for marking the two sliding blocks. The holes will need to be drilled slightly larger than the guide bar's diameter. Next, with the handle and sliding blocks on the guide bars, I laid out the holes for the five steel bushings (pieces 4). These holes need to be drilled slightly undersize to get a good press fit. I inserted the bushings using a hammer and wooden block, leaving them flush with the top surface of the sliding blocks. Threaded inserts (pieces 5) are installed at both ends of the handle and one end of each sliding block. They hold knurled-knob headed bolts (pieces 6) which secure the sliding blocks and handle to the guide bars Evenly spaced shelf holes are more attractive to the author than applied metal shelf standards. His simple and adjustable jig is sure to do long and valuable service in your shop. To make best use of the author's jig, create a drill stop from a length of dowel so you can easily register the depth of your holes. Set up the jig to line up the shelf-pin holes, and your task is almost done. in their desired positions. I installed the threaded inserts so they were just flush with the surface. My next step was to put a small radius on all the edges, using a stationary sander. Then I glued the two pieces of the handle and fence together and drilled a 1/4" hole for storing the indexing pin (piece 8) when you don't need it. I made a little knob (piece 9) from a section of dowel to top off the indexing pin. With everything else done, I sanded the assembly with 120- through 220-grit sandpaper and finished the wood with linseed oil and wax. I also used a woodburning tool with a chisel point to mark the centerlines of each sliding block. The beauty of this jig is its versatility. And if you wish to have a second set of longer guide bars.. .there will be even more opportunities to put it to good use. Reader H. Wesley Phillips, an electrical engineer by trade, has been woodworking for 25 years in South Carolina. summer 2009 41 |