Woodworker's Journal winter-2009, страница 18

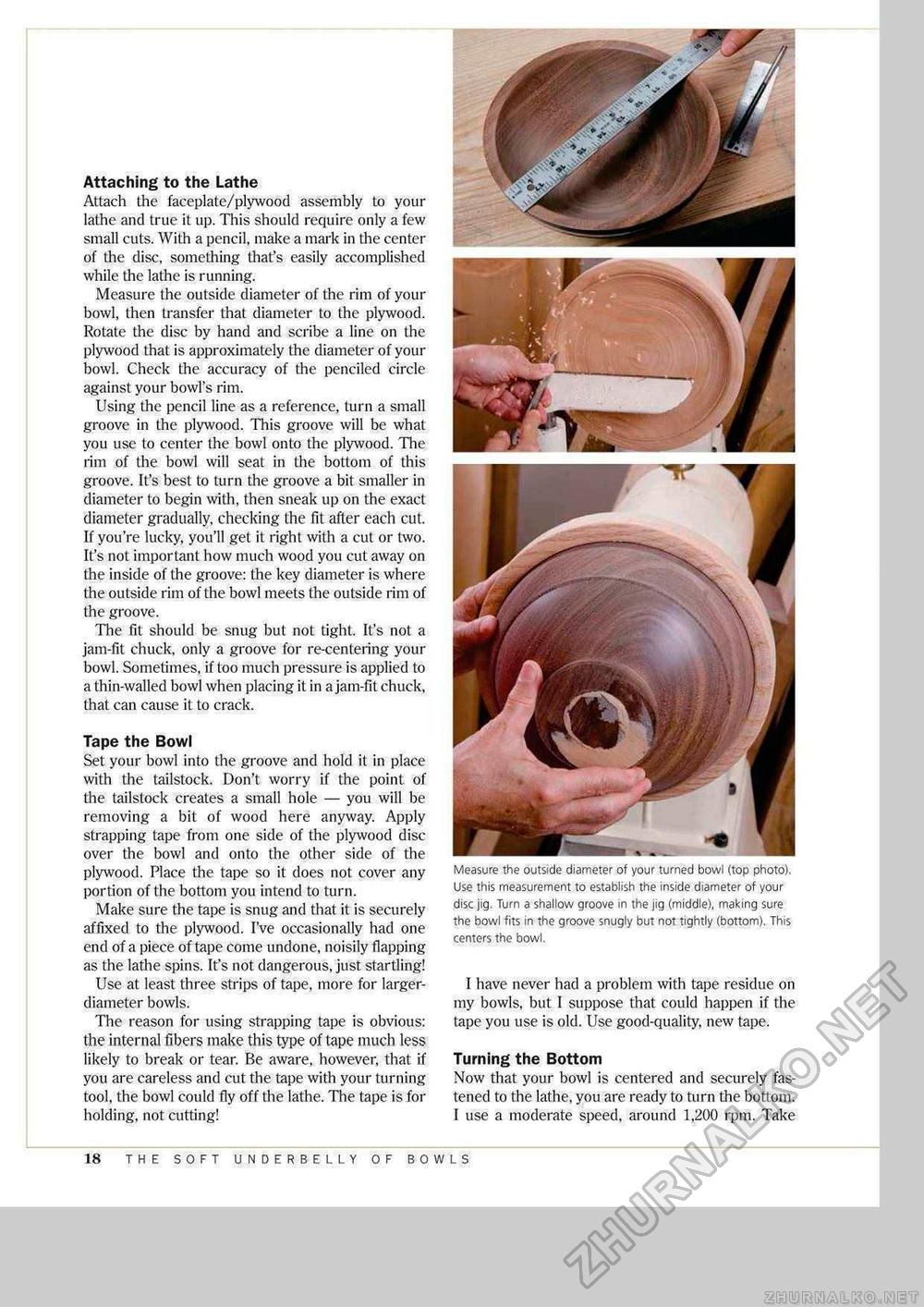

Attaching to the Lathe Attach the faceplate/plywood assembly to your lathe and true it up. This should require only a few small cuts. With a pencil, make a mark in the center of the disc, something that's easily accomplished while the lathe is running. Measure the outside diameter of the rim of your bowl, then transfer that diameter to the plywood. Rotate the disc by hand and scribe a line on the plywood that is approximately the diameter of your bowl. Check the accuracy of the penciled circle against your bowl's rim. Using the pencil line as a reference, turn a small groove in the plywood. This groove will be what you use to center the bowl onto the plywood. The rim of the bowl will seat in the bottom of this groove. It's best to turn the groove a bit smaller in diameter to begin with, then sneak up on the exact diameter gradually, checking the fit after each cut. If you're lucky, you'll get it right with a cut or two. It's not important how much wood you cut away on the inside of the groove: the key diameter is where the outside rim of the bowl meets the outside rim of the groove. The fit should be snug but not tight. It's not a jam-fit chuck, only a groove for re-centering your bowl. Sometimes, if too much pressure is applied to a thin-walled bowl when placing it in a jam-fit chuck, that can cause it to crack. Tape the Bowl Set your bowl into the groove and hold it in place with the tailstock. Don't worry if the point of the tailstock creates a small hole — you will be removing a bit of wood here anyway. Apply strapping tape from one side of the plywood discover the bowl and onto the other side of the plywood. Place the tape so it does not cover any portion of the bottom you intend to turn. Make sure the tape is snug and that it is securely affixed to the plywood. I've occasionally had one end of a piece of tape come undone, noisily flapping as the lathe spins. It's not dangerous, just startling! Use at least three strips of tape, more for larger-diameter bowls. The reason for using strapping tape is obvious: the internal fibers make this type of tape much less likely to break or tear. Be aware, however, that if you are careless and cut the tape with your turning tool, the bowl could fly off the lathe. The tape is for holding, not cutting! I have never had a problem with tape residue on my bowls, but I suppose that could happen if the tape you use is old. Use good-quality, new tape. Turning the Bottom Now that your bowl is centered and securely fastened to the lathe, you are ready to turn the bottom. I use a moderate speed, around 1,200 rpm. Take Measure the outside diameter of your turned bowl (top photo). Use this measurement to establish the inside diameter of your disc jig. Turn a shallow groove in the jig (middle), making sure the bowl fits in the groove snugly but not tightly (bottom). This centers the bowl. 18 the soft underbelly of bowls |