Woodworker's Journal winter-2009, страница 15

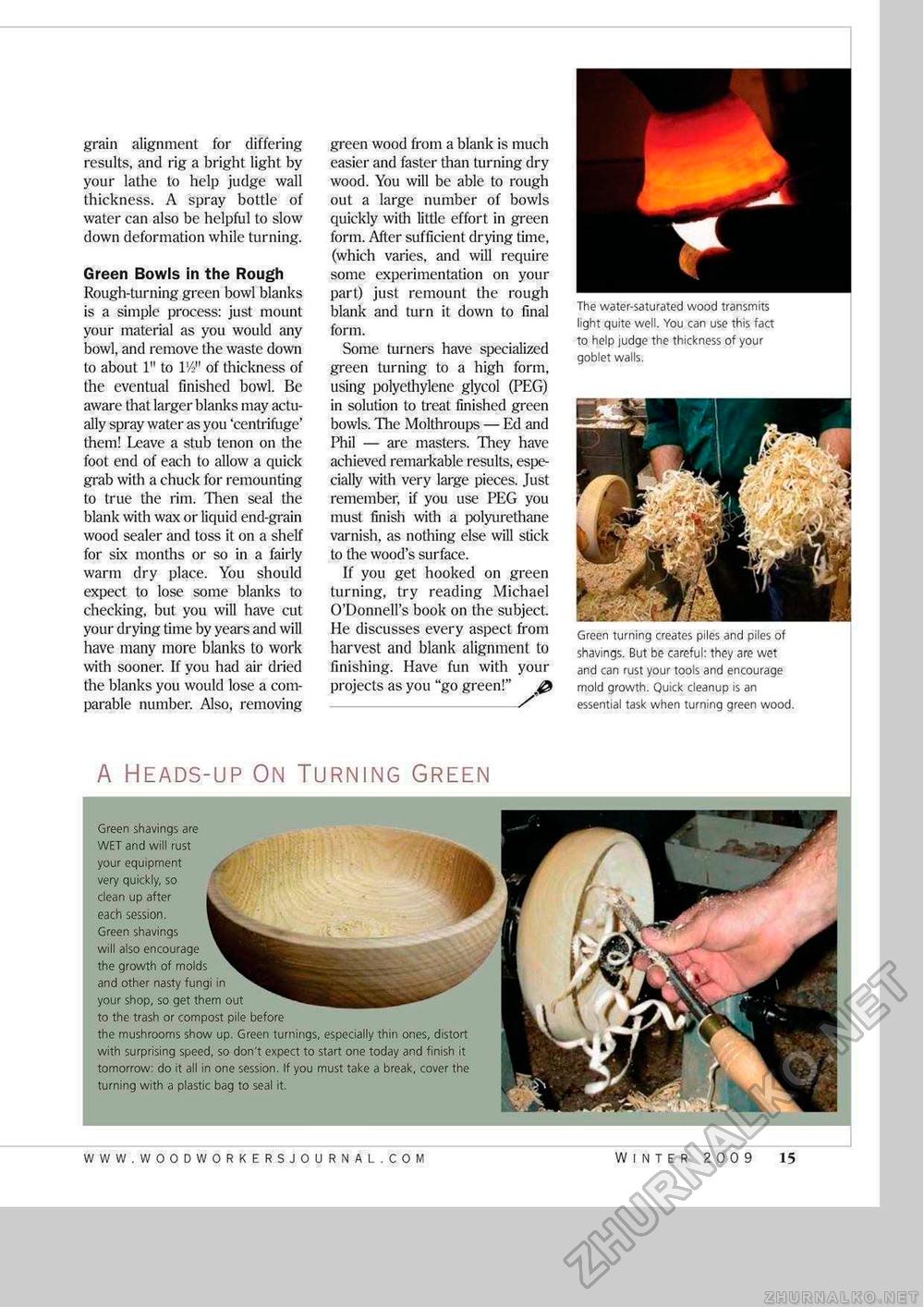

grain alignment for differing results, and rig a bright light by your lathe to help judge wall thickness. A spray bottle of water can also be helpful to slow down deformation while turning. Green Bowls in the Rough Rough-turning green bowl blanks is a simple process: just mount your material as you would any bowl, and remove the waste down to about 1" to V/J' of thickness of the eventual finished bowl. Be aware that larger blanks may actually spray water as you 'centrifuge' them! Leave a stub tenon on the foot end of each to allow a quick grab with a chuck for remounting to true the rim. Then seal the blank with wax or liquid end-grain wood sealer and toss it on a shelf for six months or so in a fairly warm dry place. You should expect to lose some blanks to checking, but you will have cut your drying time by years and will have many more blanks to work with sooner. If you had air dried the blanks you would lose a comparable number. Also, removing green wood from a blank is much easier and faster than turning dry wood. You will be able to rough out a large number of bowls quickly with little effort in green form. After sufficient drying time, (which varies, and will require some experimentation on your part) just remount the rough blank and turn it down to final form. Some turners have specialized green turning to a high form, using polyethylene glycol (PEG) in solution to treat finished green bowls. The Molthroups — Ed and Phil — are masters. They have achieved remarkable results, especially with very large pieces. Just remember, if you use PEG you must finish with a polyurethane varnish, as nothing else will stick to the wood's surface. If you get hooked on green turning, try reading Michael O'Donnell's book on the subject He discusses every aspect from harvest and blank alignment to finishing. Have fun with your projects as you "go green!" @ _ / The water-saturated wood transmits light quite well. You can use this fact to help judge the thickness of your goblet walls. Green turning creates piles and piles of shavings. But be careful: they are wet and can rust your tools and encourage mold growth. Quick cleanup is an essential task when turning green wood. A Heads-up On Turning Green Green shavings are WET and will rust your equipment very quickly, so clean up after each session. Green shavings will also encourage the growth of molds and other nasty fungi in your shop, so get them out to the trash or compost pile before the mushrooms show up. Green turnings, especially thin ones, distort with surprising speed, so don't expect to start one today and finish it tomorrow: do it all in one session. If you must take a break, cover the turning with a plastic bag to seal it. winter 2009 15 |