Woodworker's Journal winter-2009, страница 66

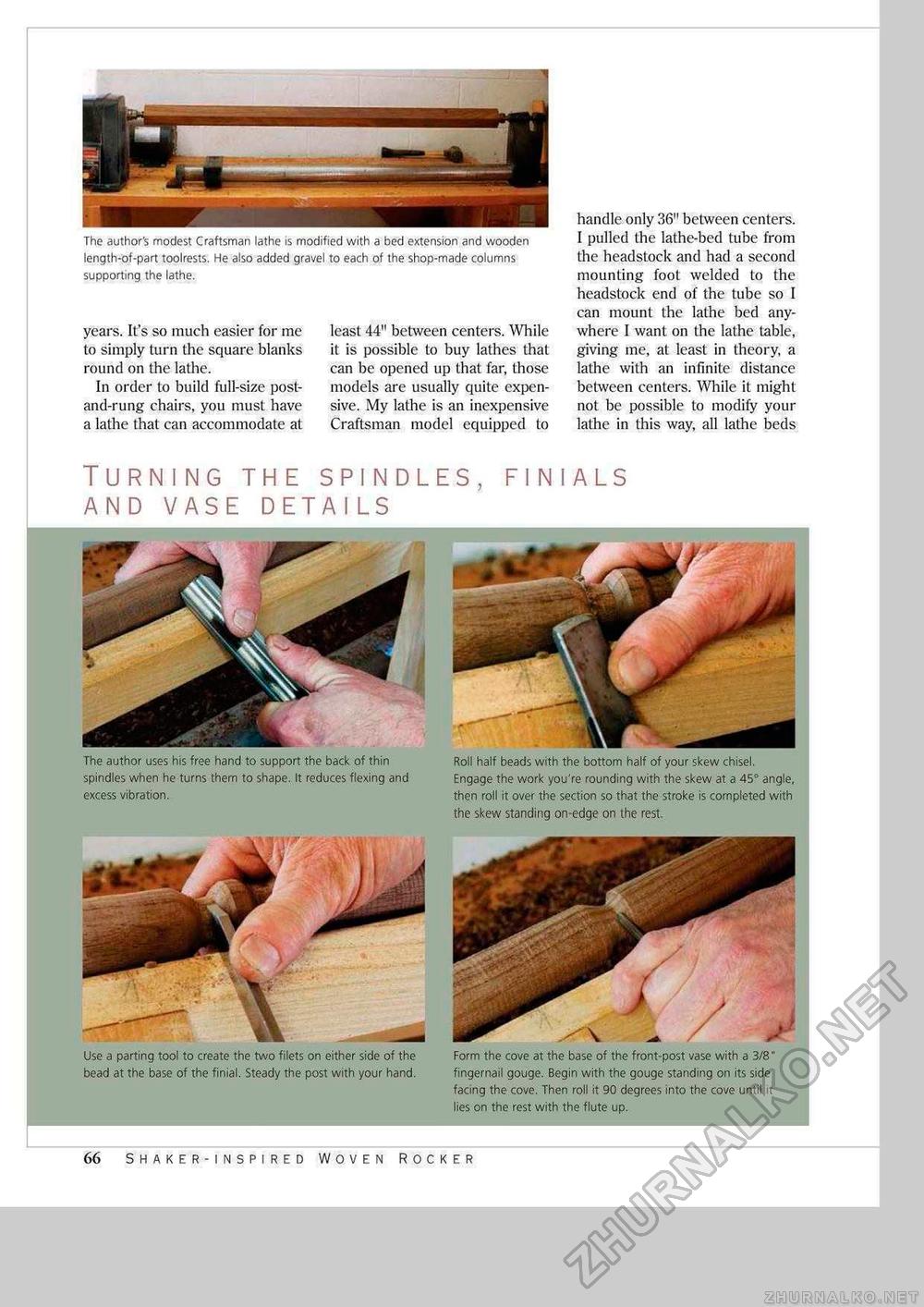

The author's modest Craftsman lathe is modified with a bed extension and wooden length-of-part toolrests. He also added gravel to each of the shop-made columns supporting the lathe. years. It's so much easier for me to simply turn the square blanks round on the lathe. In order to build full-size post-and-rung chairs, you must have a lathe that can accommodate at least 44" between centers. While it is possible to buy lathes that can be opened up that far, those models are usually quite expensive. My lathe is an inexpensive Craftsman model equipped to handle only 36" between centers. I pulled the lathe-bed tube from the headstock and had a second mounting foot welded to the headstock end of the tube so I can mount the lathe bed anywhere I want on the lathe table, giving me, at least in theory, a lathe with an infinite distance between centers. While it might not be possible to modify your lathe in this way, all lathe beds The author uses his free hand to support the back of thin spindles when he turns them to shape. It reduces flexing and excess vibration. Use a parting tool to create the two filets on either side of the bead at the base of the finial. Steady the post with your hand. Roll half beads with the bottom half of your skew chisel. Engage the work you're rounding with the skew at a 45° angle, then roll it over the section so that the stroke is completed with the skew standing on-edge on the rest. Form the cove at the base of the front-post vase with a 3/8" fingernail gouge. Begin with the gouge standing on its side facing the cove. Then roll it 90 degrees into the cove until it lies on the rest with the flute up. 66 Shaker-inspired woven Rocker |