Woodworker's Journal winter-2009, страница 67

can be lengthened, although some modifications are easier than others. Turning the Posts and Rungs Long, thin spindles tend to flex away from the tool as you turn. I'd like to suggest three techniques to counter this tendency. First, choose a mid-range lathe speed. I use 1,350 rpm. Too fast, and the spindle will vibrate in a very unsettling manner. Too slow, and the spindle's tendency to flex away from your tool is enhanced. Second, use your off hand as a steady rest. (I sometimes wrap several turns of masking tape around the palm of my right hand — I'm left-handed — and, with that protected palm, I support the back side of the turning directly opposite the lathe tool.) Be sure you keep your fingers dangling down so they can't be drawn up into the gap between the work and the rest. Third, be very careful about the way you move your tool into the work. Don't push it forward. Instead, with the handle well down, lay the heel of the bevel

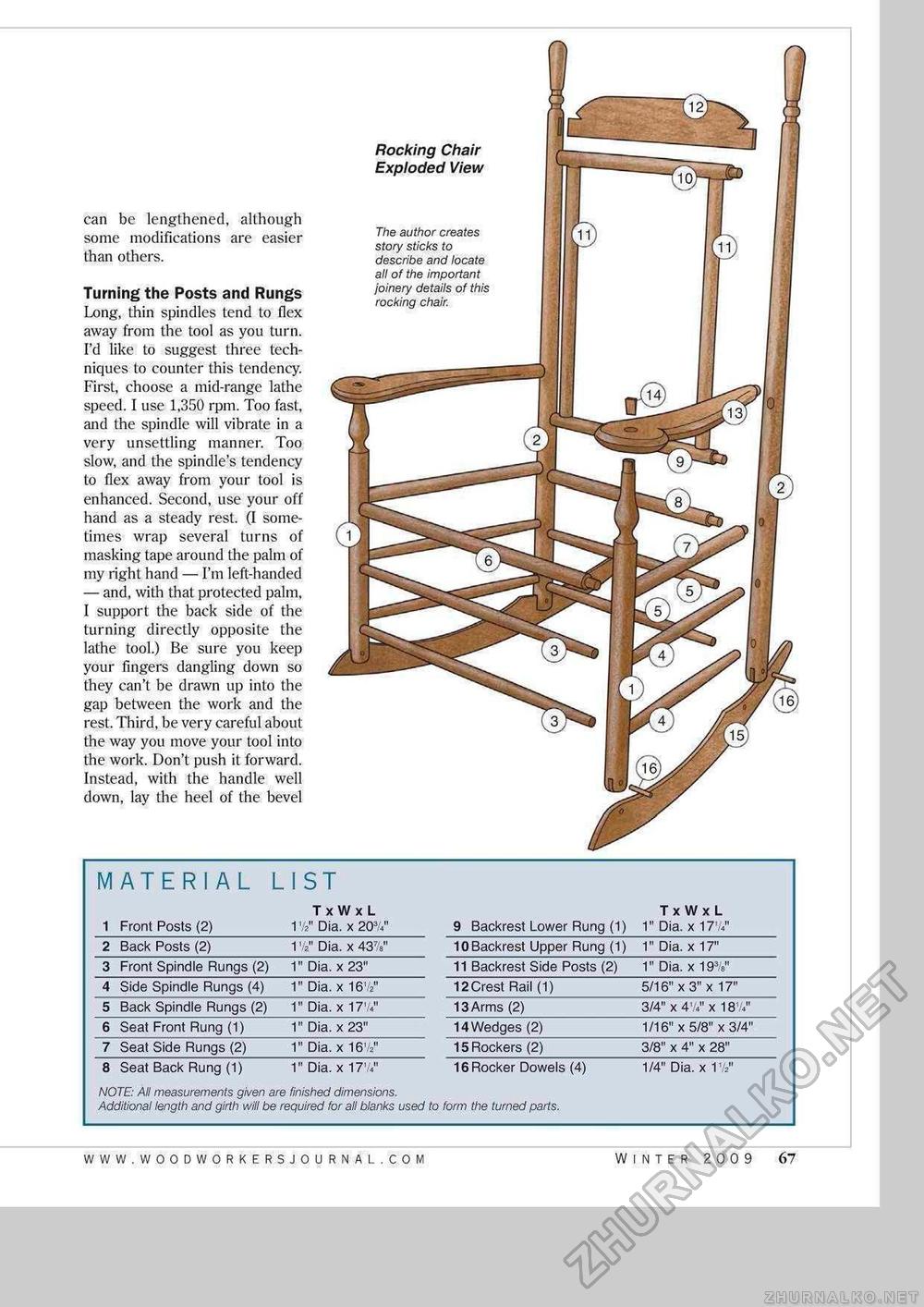

Rocking Chair Exploded View The author creates story sticks to describe and locate all of the important joinery details of this rocking chair. winter 2009 67 |

||||||||||||||||||||||||||||||||||||||||