Woodworker's Journal winter-2009, страница 70

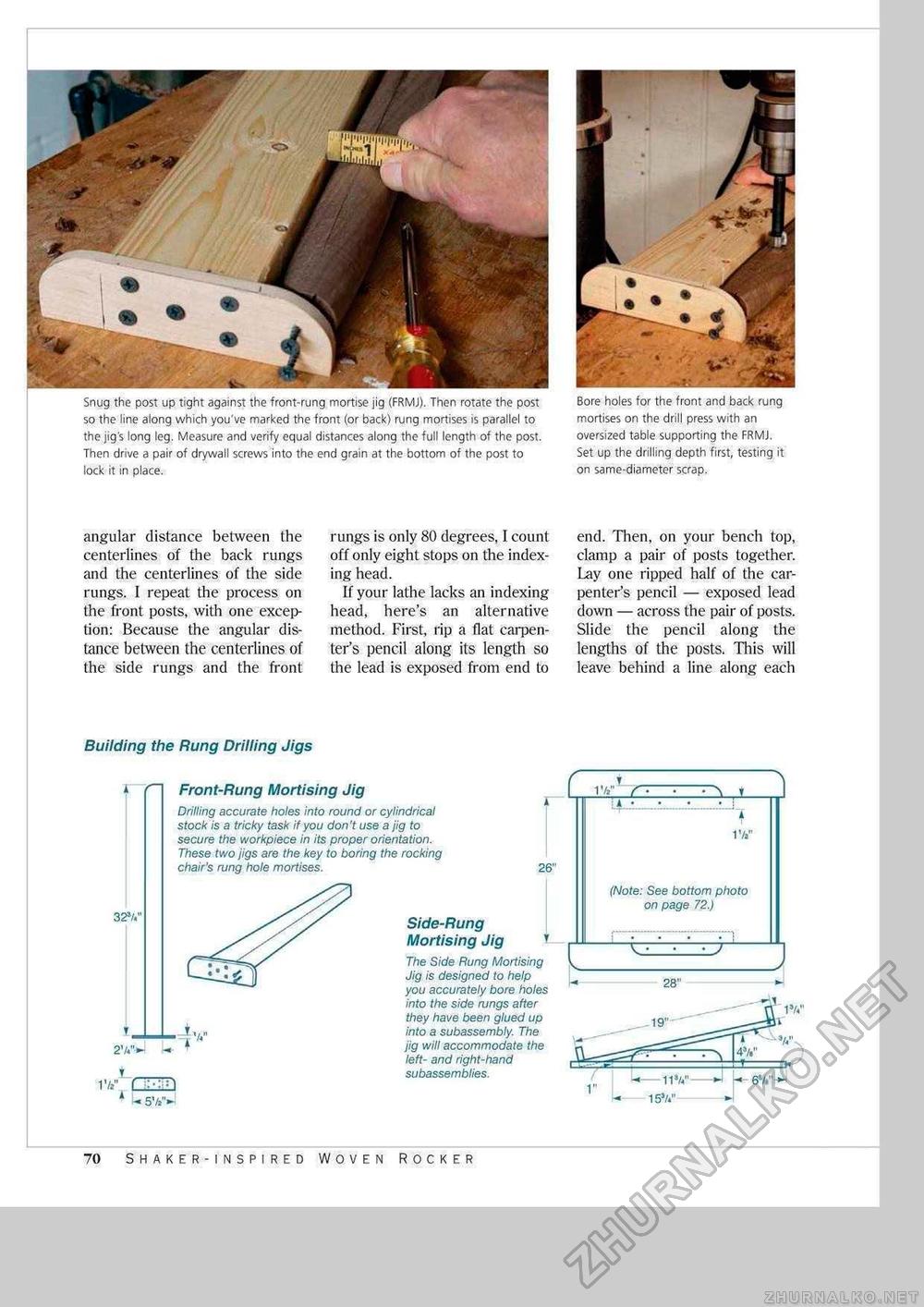

Snug the post up tight against the front-rung mortise jig (FRMJ). Then rotate the post so the line along which you've marked the front (or back) rung mortises is parallel to the jig's long leg. Measure and verify equal distances along the full length of the post. Then drive a pair of drywall screws into the end grain at the bottom of the post to lock it in place. Bore holes for the front and back rung mortises on the drill press with an oversized table supporting the FRMJ. Set up the drilling depth first, testing it on same-diameter scrap. angular distance between the centerlines of the back rungs and the centerlines of the side rungs. I repeat the process on the front posts, with one exception: Because the angular distance between the centerlines of the side rungs and the front rungs is only 80 degrees, I count off only eight stops on the indexing head. If your lathe lacks an indexing head, here's an alternative method. First, rip a flat carpenter's pencil along its length so the lead is exposed from end to end. Then, on your bench top, clamp a pair of posts together. Lay one ripped half of the carpenter's pencil — exposed lead down — across the pair of posts. Slide the pencil along the lengths of the posts, This will leave behind a line along each Building the Rung Drilling Jigs 327." Y_ 27." > Front-Rung Mortising Jig Drilling accurate holes into round or cylindrical stock is a tricky task if you don't use a jig to secure the workpiece in its proper orientation. These two jigs are the key to boring the rocking chair's rung hole mortises. iv rwi Side-Rung Mortising Jig The Side Rung Mortising Jig is designed to help you accurately bore holes into the side rungs after they have been glued up into a subassembly. The jig will accommodate the left- and right-hand subassemblies. 26" iv." r A 17." (Note: See bottom photo on page 72.)

70 Shaker-inspired woven Rocker |