Creative Woodworks & crafts 2001-06, страница 32

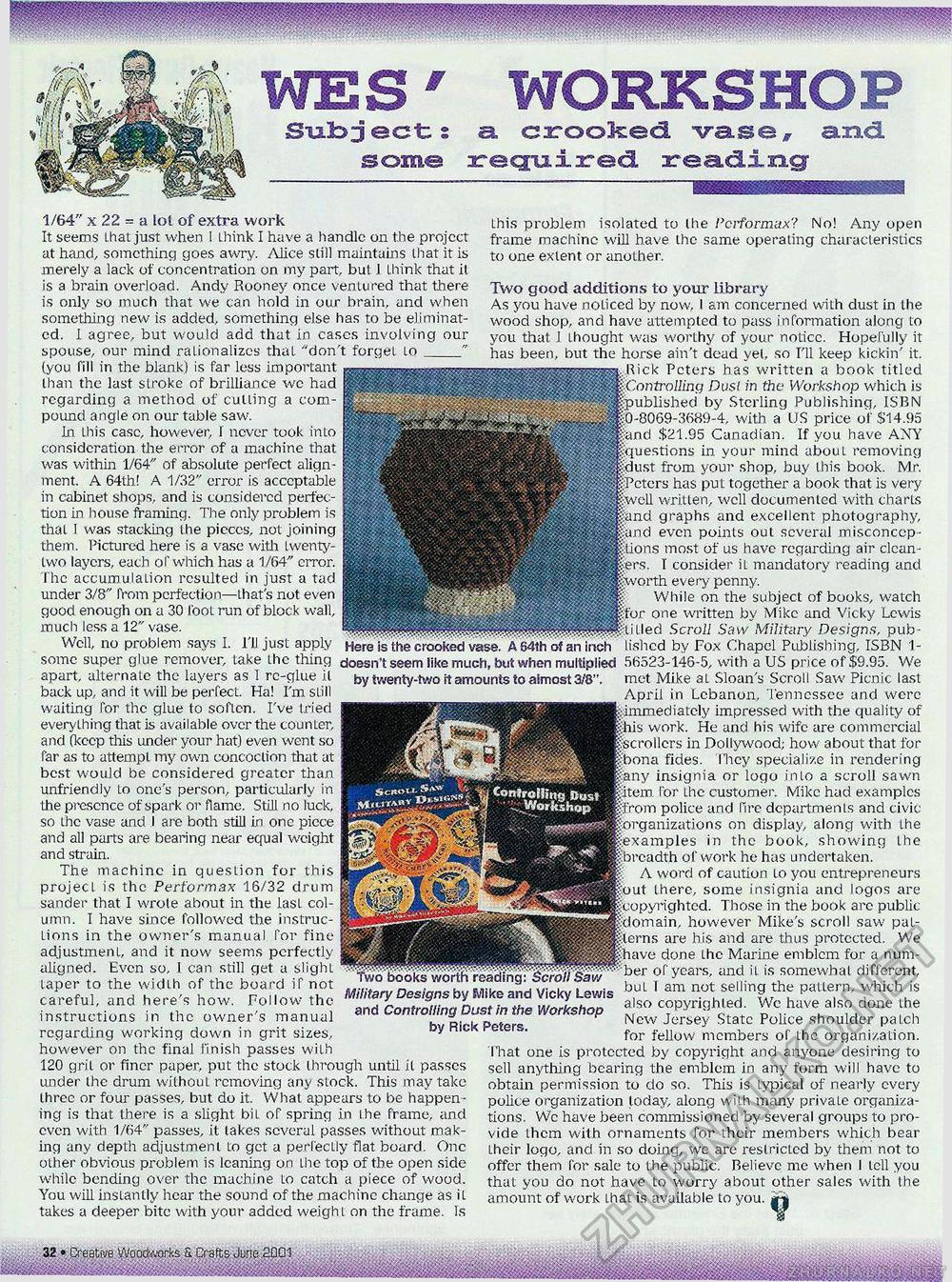

SMMwtSf V'/ * w'-i WES' WORKSHOP S"ui> j ecfc: a crooked ysssm and some required. rea.dxxicjr 32 « .Creative Woodworks S Crafts June 2QQ1 IS81S1 1/64" x 22 = a lot of extra work It seems that just when I think I have a handle on the projcct at hand, something goes awry. Alice still maintains that it is merely a lack of concentration on my part, but J think that it is a brain overload. Andy Ftooney once ventured that there is only so much that we can hold in our brain, and when something new is added, something else has to be eliminated. I agree, but would add that in eases involving our spouse, our mind rationalizes that "don't forget to_" (you fill in the blank) is far less important than the last stroke of brilliance wc had regarding a method of cutting a compound angle on our table saw. In this ease, however, 1 never took into consideration the error of a machine that was within 1/64" of absolute perfect alignment. A 64th! A 1/32" error is acccptable in cabinet shops, and is considered perfection in house framing. The only problem is that I was stacking the picces, not joining them. Pictured here is a vase with twenty-two layers, each of which has a 1/64" error. The accumulation resulted in just a tad under 3/8" from perfection—that's not even good enough on a 30 loot run of block wall, much less a 12" vase. Well, no problem says I. 1U just apply some super glue remover, take Lhc thing apart, alternate the layers as I rc-glue it back up, and it will be perfect. Ha! I'm still waiting Tor the glue to soften. I've Iried everything that is available over the counter, and (keep this tinder your hat) even went so Par as to attempt my own concoction that at best would be considered greater than unfriendly to one's person, particularly in the prcscnce of spark or flame. Still no luck, so lhc vase and I are both still in one picce and all parts are bearing near equal weight and strain. The machinc in question for this project is the Performax 16/32 drum sander that I wrote about in the last, column. I have since followed the instructions in the owner's manual for fine adjustment, and it now seems perfectly aligned. Even so, I can still get a slighL taper to the width of the board if not careful, and here's how. Follow the instructions in the owner's manual regarding working down in grit sizes, however on the final finish passes with Lhis problem isolated to the I'crformux? No! Any open frame machine will have the same operating characteristics to one extent or another. Here is the crooked vase, A 64th of an inch 120 grit or finer paper, put the stock through until it passes under the drum without removing any stock. This may take three or four passes, but do it. What appears to be happening is that there is a slight bit of spring in the frame, and even with 1/64" passes, it lakes several passes without making any depth adjustment to get a perfectly flat board. One other obvious problem is leaning on the top of the open side while bending over the machine to catch a piece of wood. You will instantly hear the sound of the machinc change as it takes a deeper bite with your added weight on the frame. Is Two good additions to your library As you have noticed by now, I am concerned with dust in the wood shop, and have attempted to pass information along to you that. I thought was worthy of your noticc. Hopefully it has been, but the horse ain't dead yet, so I'll keep kickin' it. thick Peters has written a book titled |C on fro Ming Dusl in the Workshop which is ^published by Sterling Publishing, ISBN £0-8069-3689-4, with a US price of $14.95 |and $21.95 Canadian. If you have ANY ^questions in your mind abouL removing Kdust from your shop, buy this book. Mr. |fPcters has put together a book that is very gwell written, well documented with charts |and graphs and excellent photography, |and even points out several misconccp-j|tions most of us have regarding air clean-|'ers. I consider it mandatory reading and |worth every penny. While on the subject of books, watch |for one written by Mike and Vicky Lewis P§|i.il.led Scroll Saw Military Designs, published by Fox Chapel Publishing, ISBN 1-doesn't seem like much, but when multiplied 56523-146-5, with a US price of $9.95. We by twenty-two ft amounts to almost 3/8". met Mike at Sloan's Scroll Saw Picnic last April in Lebanon, Tennessee and were ^immediately impressed with the quality of |his work. He and his wife are commercial |scrollcrs in Hollywood; how about that for ibona fides. They specialize in rendering £any insignia or logo into a scroll sawn litem Cor the customer. Mike had examples |from police and lire departments and civic ^organizations on display, along with the ^examples in the book, showing the Ibrcadth of work he has undertaken. A word of caution Lo you entrepreneurs lout there, some insignia and logos are I'copyTightcd. Those in the book arc public Idomain, however Mike's scroll saw patterns are his and are thus protected. We jihave done the Marine emblem for a number of years, and it is somewhat different, buL I am not selling the pattern, which is also copyrighted. We have also done the New Jersey State Police shoulder patch for fellow members of Lhc organization, that one is protected by copyright and anyone desiring to sell anything bearing the emblem in any form will have to obtain permission to do so. This is Lypical of nearly every police organization today, along with many private organizations. Wc have been commissioned by several groups to provide them with ornaments for their members which bear Lhcir logo, anc.1 in so doing, wc are restricted by them not to offer them for sale to the public. Relieve me when I tell you that you do not have Lo worry about other sales with the amount of work that is available to you. jrj two books worth reading:' Scroti Saw Military Designs by Mike and Vicky Lewis and Controlling Dust in the Workshop by Rick Peters. |