Creative Woodworks & crafts 2002-04, страница 22

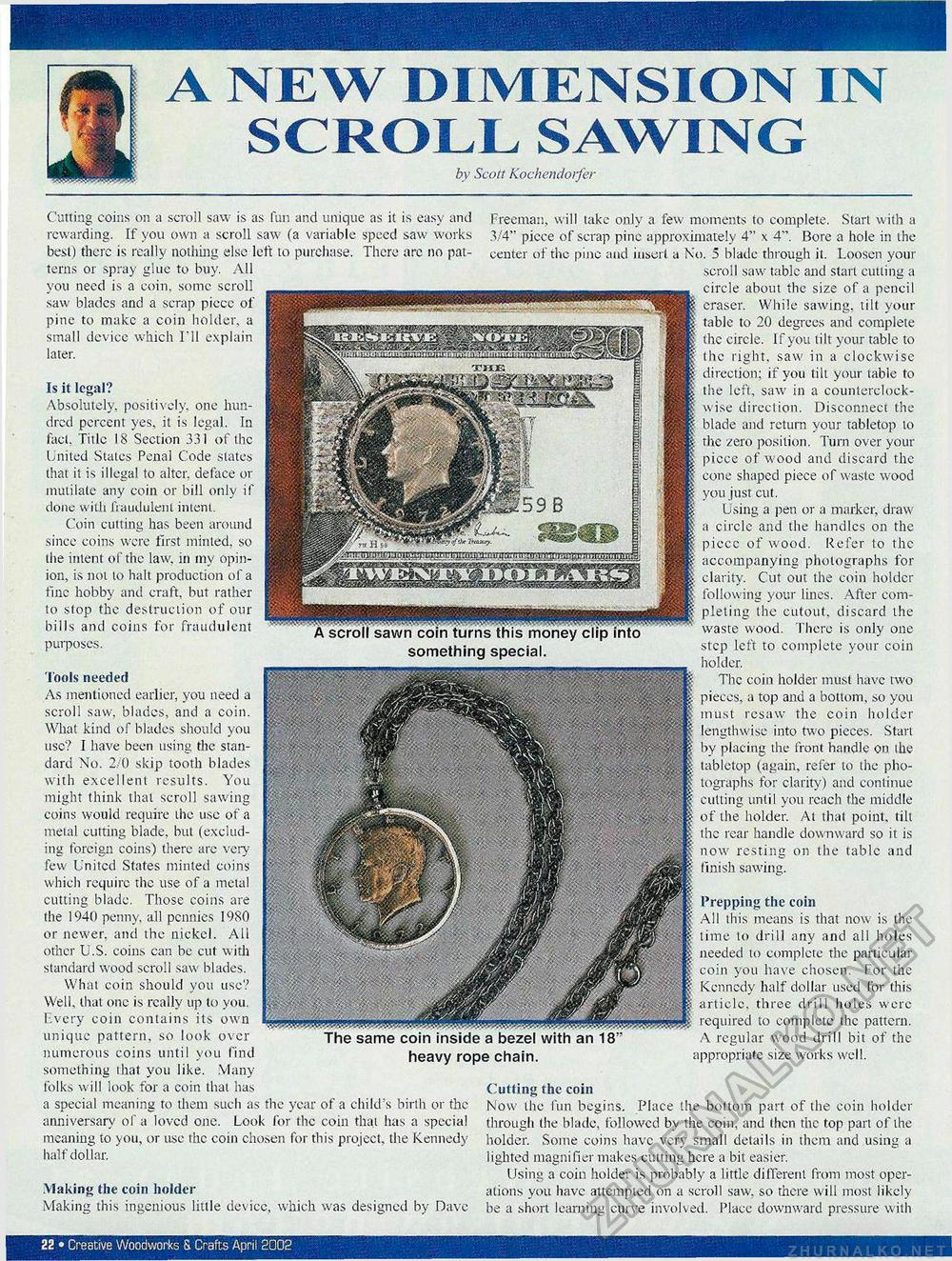

A NEW DIMENSION IN SCROLL SAWING by Scott Kochendorfer Cutting coins on a scroll saw is as fun and unique as it is easy and rewarding. If you own a scroll saw (a variable speed saw works best) there is really nothing else left to purchase. There are no patterns or spray glue to buy. All you need is a coin, some scroll saw blades and a scrap piecc of pine to make a coin holder, a small device which I'll explain later. Is it legal? Absolutely, positively, one hundred percent yes, it is legal. In fact. Title 18 Section 33 f of the United Stales Penal Code slates that it is illegal to alter, deface or mutilate any coin or bill only if done with fraudulent intent. Coin cutting has been around since coins were first minted, so the intent of the law, in my opinion, is not to halt production of a tine hobby and craft, but rather to stop the destruction of our bills and coins for fraudulent purposes. something special. Tools needed As mentioned earlier, you need a scroll saw, blades, and a coin. What kind of blades should you use? I have been using the standard No. 2/0 skip tooth blades with excellent results. You might think that scroll sawing coins would require the use of a metal cutting blade, but (excluding foreign coins) there arc very few United States minted coins which require the use of a metal cutting blade. Those coins are the 1940 penny, all pennies 1080 or newer, and the nickel. All other U.S. coin?* can be cut with standard wood scroll saw blades. What coin should you use? Well, that one is really up to you. l-very coin contains its own unique pattern, so look over numerous coins until you find something that you like. Many folks will look for a coin thai has a special meaning to them such as the year of a child's birth or the anniversary of a loved one. Look for the coin that has a special meaning to you, or use the coin chosen for this project, the Kennedy half dollar. Making the coin holder Making this ingenious little device, which was designed by Dave heavy rope chain. Freeman, will take only a few moments to complete. Start with a 3/4" piece of scrap pine approximately 4" x 4". Bore a hole in the center of the pine and insert a No. 5 blade through it. Loosen your scroll saw table and start cutting a circle about the size of a pencil eraser. While sawing, tilt your table to 20 degrees and complete the circle. If you lilt your table to the right, saw in a clockwise direction; if you tilt your table to the left, saw in a counterclockwise direction. Disconnect the blade and return your tabletop to the zero position. Turn over your piece of wood and discard the cone shaped piece of waste wood you just cut. Using a pen or a marker, draw a circle and the handles on the piecc of wood. Refer to the accompanying photographs for clarity. Cut out the coin holder following your lines. After completing the cutout, discard the waste wood. There is only one step left to complete your coin holder. The coin holder must have two pieces, a top and a bottom, so you must resavv the coin holder lengthwise into two pieces. Start by placing the front handle on the tabletop (again, refer to the photographs for clarity) and continue cutting until you reach the middle of the holder. At that point, tilt the rear handle downward so it is now resting on the table and finish sawing. l'repping the coin All this means is that now is the time to drill any and all holes needed to complete the particular coin you have chosen. For the Kennedy half dollar used for this article, three drill holes were required to complete the pattern. A regular wood drill bit of the appropriate size works well. Cutting the coin Now the fun begins. Place the bottom part of the coin holder through the blade, followed by the coin, and then the top part of the holder. Some coins have very small details in them and using a lighted magnifier makes cutting here a bit easier. Using a coin holder is probably a little different from most operations you have attempted on a scroll saw, so there will most likely be a short learning curve involved. Place downward pressure with 22 • Creative Woodworks & Crafts April 2002 |