Creative Woodworks & crafts 2003-01, страница 46

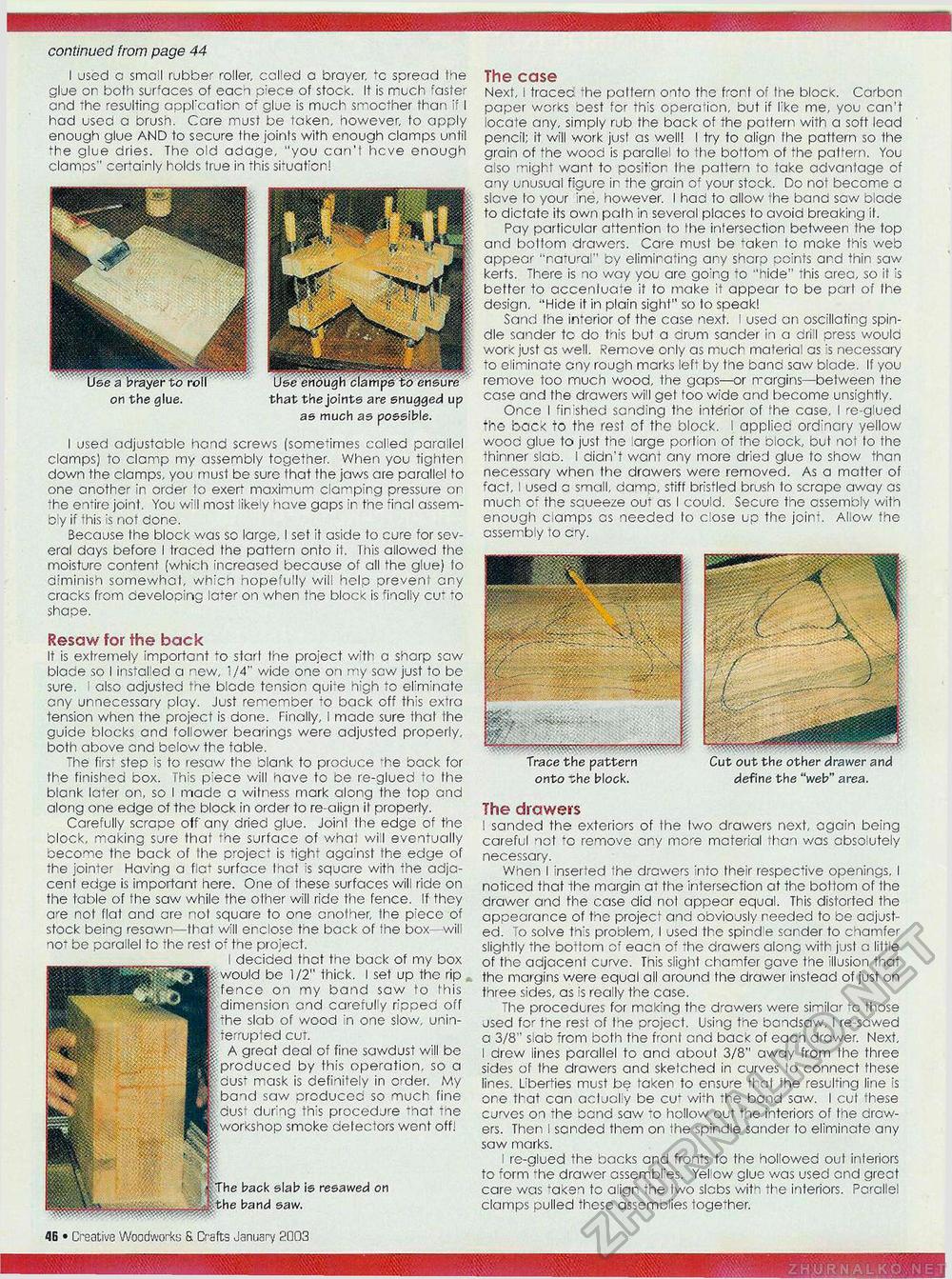

v - continued from page 44 I used o small rubber roller, called a brayer, tc spread the glue or both surfaces of eacn p:ece of stock. It is much "'aster and The resulting appl'catior of glue is much smoother than if I had used a brush. Care must be taken, however, to apply enough glue AND to secure the joints with enough clamps until the glue dries. The old adage, "you can't heve enough clamos" certa'rly holds true in this siruat:cr! on the glue. that the joints are snugged up as much as possible. I used adjustable hand screws (sometimes called parallel clamps) to clamp my assembly together. When you tighten down the clamps, you must be sure that the jaws are parallel to one another in order to exert maximum clamping pressure on the entire joint. You will most likely have gaps in tne final assembly if this is not done. Because the block was so large, I set it aside to cure for several days before I traced the pattern onto it. I his allowed the moisture content (which increased because of all the glue) to diminish somewhat, wh'ch hopefully will help prevent any cracks from developing late"- on when the block is finally cu" to shape. The case Next, i tracec 'he pattern onto the frort of Ihe blocK. Carbcn paper works best for this operation, but if like me, you can't locate any, simply rub the back of the pattern with a soft lead pencil; it will work just as well! I try to align the pattern so the grain of the wood is parallel to the bottom of the pattern. You also might wart to position Ihe pattern to take advantage of any unusual figure in the grain of your stock. Do not become a slave lo your ine, however. I had to allow the band saw blade to dictate its own palh in several places to avoid breaking it. Pay particular attention to the intersection between the top and bottom drawers. Care must be taken to make this web appear "natural" by elimirating any sharp ooints ard thin saw kerfs. There is no way you are going "o "hide" This area, so it Is better to accenluate it to make it appear to be part of the design. "Hide if in plain sight" so lo speak! Sand the interior of the case next. I used on oscillating spindle sander to do this but a drum sander in a drill press would wor< just as well. Remove only as much material as's necessary to eliminate any rough marks left by the band saw blade. If you remove too much wood, the gaps—or margins—between the case and the drawers will gel too wide and become unsightly. Once I fin;shed sanding the interior of the case. I re-glued the bac< to the rest cf the block. I applied ord'nary yellow wood glue to just tne arge portion of the oiock, but not lo the thinner slab. I didn't want any more dried glue to show than necessary when the drawers were removed. As a matter of fact, I used a small, damp, stiff bristled brush to scrape away as much of the saueeze out as I could. Secure the assembly with enough c amps cs needed lo close up the joir*. Al ow the assembly to cry. Cut out the other drawer and define the "web" area. The drawers I sanded the exteriors of the two drawers next, again being careful not -o remove any more material than was absolutely necessary. When I inserted the drawers into their respective openings, I noticed that the margin at the intersection at the bottom of the drawer and the case did nol appear equal. This distorted the apoearance of the project and obviously needed to be adjusted. o solve tn's proolem, I used the spind e sender to chamfer slightly the bottom of eacn of "he drawers along with just o little of the adjacent curve. This slight chamfer gave the illusion that the margins were equal ail around the drawer instead ot just on three sides, as is really the case. The procedures for mak'ng the d'awers were similar to those used for tne rest of Ine project. Using the bandsaw, I re-sowed a 3/8" slab from both the front and back of each drawer. Next, I drew lines parallel to and about 3/8" away from the three sides of the drawers and sketched in curves lo connect these lines, liberties must be taken to ensure thai the resulting line is one that can acljally be cu* whh the band saw. I cut these curves on "he oand saw -o hollow out the interiors of Ine drawers. Then I sanded them on the spindle sander to eliminate any saw marks. I re-glued the backs and fronts to the hollowed out interiors to ;orm *he drawer cssembl:es. Yelow glue was used and great care was "a<sn to align the two slcbs with the interiors. Parallel clamps pulled these assemblies together. 4B • Creative Woodworks & Crafts January 2003 Resaw for the back It is extremely important to start Ihe project with a sharp saw blade so I instal ed a new, 1/4" wide one on my saw just to be sure, also adjusted Tne blade tension qui'e high to el'mlnate any unnecessary play. Just remember -o back off this extra tension when the project is done. Finally, 1 made sure that the guide blocks and follower bearings were adjusted properly, both above ond below the fable. "he firs" step ;5 to resaw the blank to produce "he back for the finished box. This p'ece will have to be re-glued to the blank later on, so I made a witness mark along the top and along one edge ot the block in order to re-align il properly. Carefully scrape off any dried glue. Joinl Ihe edge of the block, making sure that The surface of whal will eventually become the back of the project is tight aga'nst the edge of the jointer Having a flat surface that is square with the adjacent edge is important here. One of these surfaces will ride on the table of the saw while the other will ride the fence. If they are nol flat and are nol square to one another, the pleco of stock being resawn—that will enclose tne back of the box wil not be parallel to ihe rest of tne project. I decided that the back of my box would be 1/2" thick. I set up the rip fence on my band saw to this dimension and carefuiy ripped off the slab of wood n one slow, uninterrupted cut. A great deal of fine sawdust will be produced by this operation, so a dust mask is definitely in order. My band saw prcduccc so much fine dusi during this procedure rnat tne workshop smoke deleciors went offl The back slab is resawed on the band saw. ■S'-SV-V Trace the pattern onto 'he block. |