Creative Woodworks & crafts 2005-11, страница 55

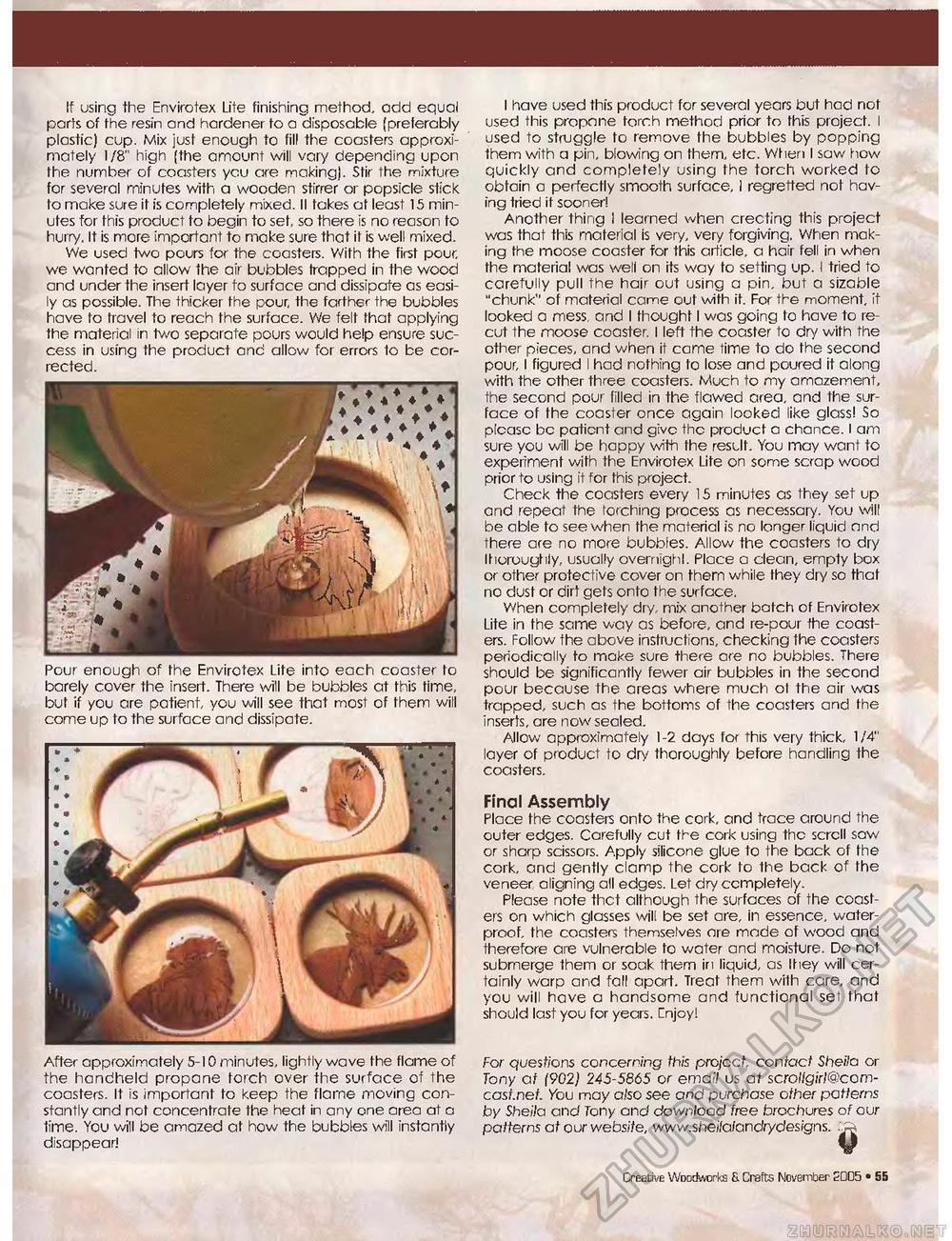

If using the Envirotex Lite finishing method, odd equal parts of the resin and hardener to a disposable (preferably plastic) cup. Mix just enough to fill the coasters approximately 1/8" high (the amount will vary depending upon the number of coasters you are making). Stir the mixture for several minutes with a wooden stirrer or popsicle stick to make sure if is completely mixed. II fakes at least 15 minutes for this product to begin to set, so there is no reason to hurry. It is more important to moke sure that it is well mixed. We used two pours for the coasters. With the first pour, we wanted to allow the air bubbles trapped in the wood and under the insert layer to surface and dissipate as easily as possible. The thicker the pour, the farther the bubbles have to travel to reach the surface. We felt that applying the material in two separate pours would help ensure success in using the product and allow for errors to be corrected. Pour enough of the Envirotex Lite into each coaster to barely cover the insert. There will be bubbles at this time, but if you are patient, you will see that most of them will come up to the surface and dissipate. After approximately 5-10 minutes, lightly wave the flame of the handheld propane torch over the surface of the coasters. It is important to keep the flame moving constantly and not concentrate the heat in any one area at a lime. You will be amazed at how the bubbles will instantly disappear! I have used this product for several years but had not used this propane torch method prior to this project. I used to struggle to remove the bubbles by popping them with a pin, blowing on them, etc. When I saw how quickly and completely using the torch worked to obtain a perfectly smooth surface, I regretted not having tried it sooner! Another thing I learned when crecting this project was that this material is very, very forgiving, When making the moose coaster for this article, a hair fell in when the material was well on its way to setting up. I tried to carefully pull the hair out using a pin, but a sizable "chunk" of material came out with it. For the moment, it looked a mess, and I thought I was going to have to re-cut the moose coaster. I left the coaster to dry with the other pieces, and when it carne time to do the second pour, I figured I had nothing to lose and poured it along with the other three coasters. Much to my amazement, the second pour filled in the flawed area, and the surface of the coaster once again looked like glass! So please bo patient and give the product a chance. I am sure you will be happy with the result. You may want to experiment with the Envirotex Lite on some scrap wood prior to using it for this project. Check the coasters every 15 minutes as they set up and repeat the torching process as necessary. You will be able to see when the material is no longer liquid and there are no more bubbtes. Allow the coasters to dry Ihoroughly, usually ovemighl. Place a clean, empty box or other protective cover on them while they dry so that no dust or dirt gets onto the surface. When completely dry, mix another batch of Envirotex Lite in the same way as before, and re-pour the coasters. Follow the above instructions, checking the coasters periodically to make sure there are no bubbles. There should be significantly fewer air bubbles in the second pour because the areas where much of the air was trapped, such as the bottoms of the coasters and the inserts, are now sealed. Allow approximately 1-2 days for this very thick, 1/4" layer of product to dry thoroughly before handling the coasters. Final Assembly Place the coasters onto the cork, and trace around the outer edges. Carefully cut the cork using the scroll saw or sharp scissors. Apply silicone glue to the back of the cork, and gently clamp the cork to the back of the veneer aligning all edges. Let dry completely. Please note thct although the surfaces of the coasters on which glasses will be set are, in essence, waterproof, the coasters themselves ore made of wood and therefore are vulnerable to water and moisture. Do not submerge them or soak them in liquid, as Ihey will certainly warp and fall apart. Treat them with care, and you will hove a handsome and functional set that should last you for years. Enjoy! For questions concerning this prcjcct, contact Sheila or Tony at (902) 245-5865 or email us af scrollgirl@com-cast.net You may also see and purchase other patterns by Sheila and Tony and download free brochures of our patterns at our website, www.sheilalandrydesigns. ^ Creative Woodworks 6. Crafts November 2005 « 5 |