Popular Woodworking 2000-10 № 117, страница 38

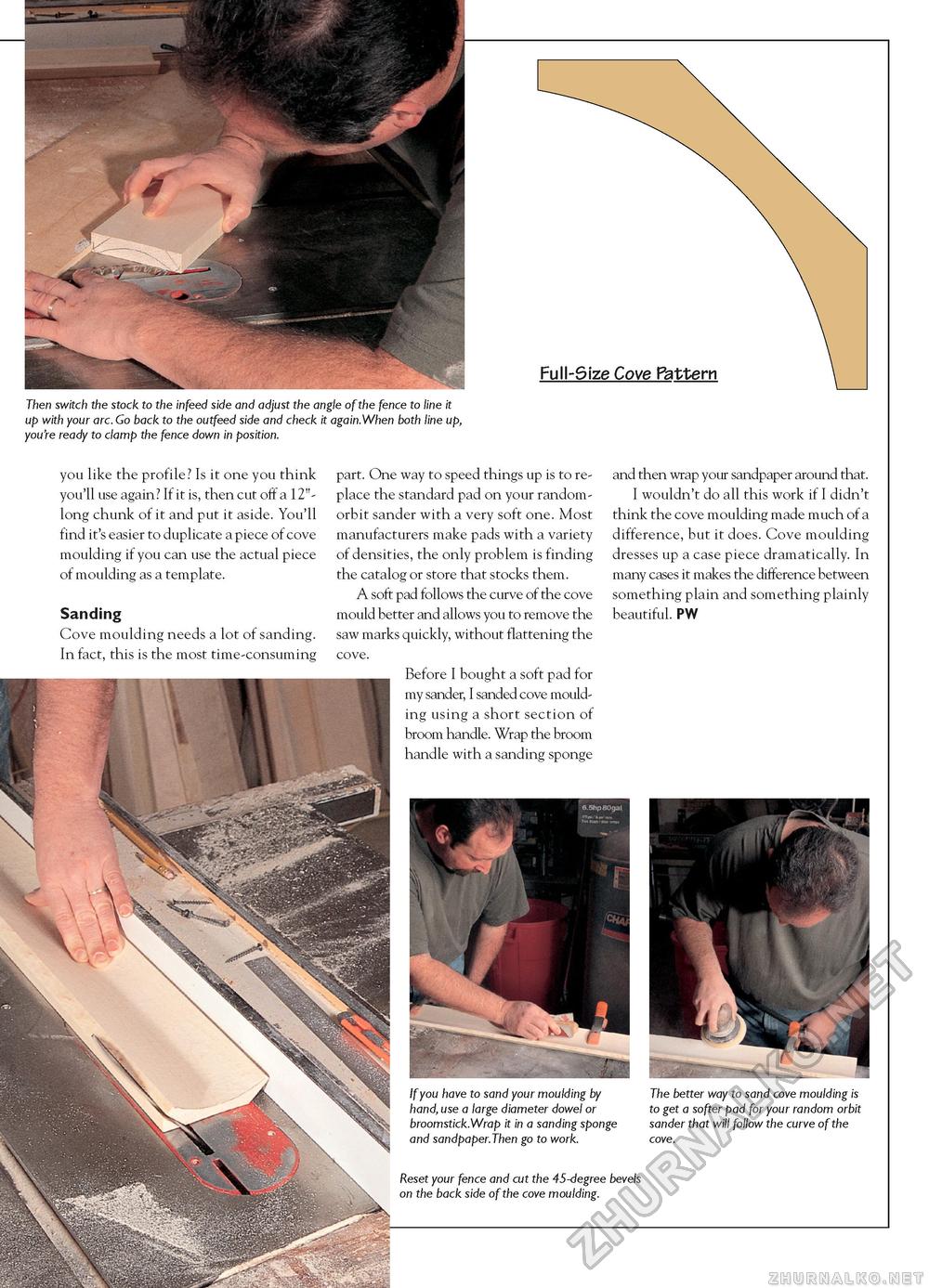

you like the profile? Is it one you think you'll use again? If it is, then cut off a 12"-long chunk of it and put it aside. You'll find it's easier to duplicate a piece of cove moulding if you can use the actual piece of moulding as a template. Sanding Cove moulding needs a lot of sanding. In fact, this is the most time-consuming part. One way to speed things up is to replace the standard pad on your random-orbit sander with a very soft one. Most manufacturers make pads with a variety of densities, the only problem is finding the catalog or store that stocks them. A soft pad follows the curve of the cove mould better and allows you to remove the saw marks quickly, without flattening the Before I bought a soft pad for my sander, I sanded cove moulding using a short section of broom handle. Wrap the broom handle with a sanding sponge and then wrap your sandpaper around that. I wouldn't do all this work if I didn't think the cove moulding made much of a difference, but it does. Cove moulding dresses up a case piece dramatically. In many cases it makes the difference between something plain and something plainly beautiful. PW If you have to sand your moulding by hand, use a large diameter dowel or broomstick.Wrap it in a sanding sponge and sandpaper.Then go to work. Reset your fence and cut the 45-degree bevels on the back side of the cove moulding. The better way to sand cove moulding is to get a softer pad for your random orbit sander that will follow the curve of the cove. |