Popular Woodworking 2000-10 № 117, страница 48

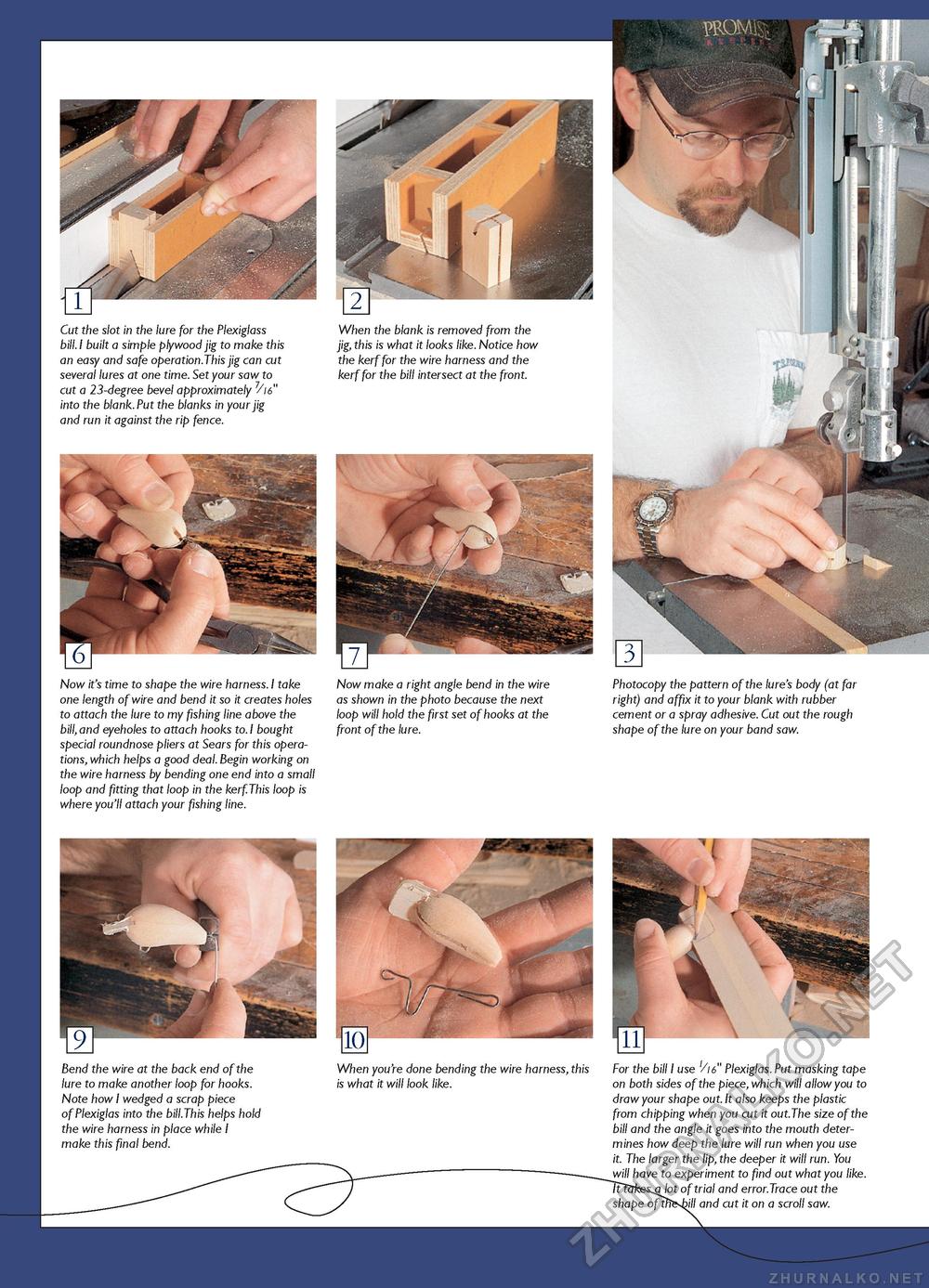

Cut the slot in the lure for the Plexiglass bill. I built a simple plywood jig to make this an easy and safe operation.This jig can cut several lures at one time. Set your saw to cut a 23-degree bevel approximately 7//6" into the blank. Put the blanks in your jig and run it against the rip fence. When the blank is removed from the jig, this is what it looks like. Notice how the kerf for the wire harness and the kerf for the bill intersect at the front. Now it's time to shape the wire harness. I take one length of wire and bend it so it creates holes to attach the lure to my fishing line above the bill, and eyeholes to attach hooks to. I bought special roundnose pliers at Sears for this operations, which helps a good deal. Begin working on the wire harness by bending one end into a small loop and fitting that loop in the kerf. This loop is where you'll attach your fishing line. Now make a right angle bend in the wire as shown in the photo because the next loop will hold the first set of hooks at the front of the lure. Photocopy the pattern of the lure's body (at far right) and affix it to your blank with rubber cement or a spray adhesive. Cut out the rough shape of the lure on your band saw. Bend the wire at the back end of the lure to make another loop for hooks. Note how I wedged a scrap piece of Plexiglas into the bill.This helps hold the wire harness in place while I make this final bend. When you're done bending the wire harness, this is what it will look like. For the bill I use Plexiglas. Put masking tape on both sides of the piece, which will allow you to draw your shape out. It also keeps the plastic from chipping when you cut it out.The size of the bill and the angle it goes into the mouth determines how deep the lure will run when you use it. The larger the lip, the deeper it will run. You will have to experiment to find out what you like. It takes a lot of trial and error.Trace out the shape of the bill and cut it on a scroll saw. |