Popular Woodworking 2001-02 № 120, страница 45

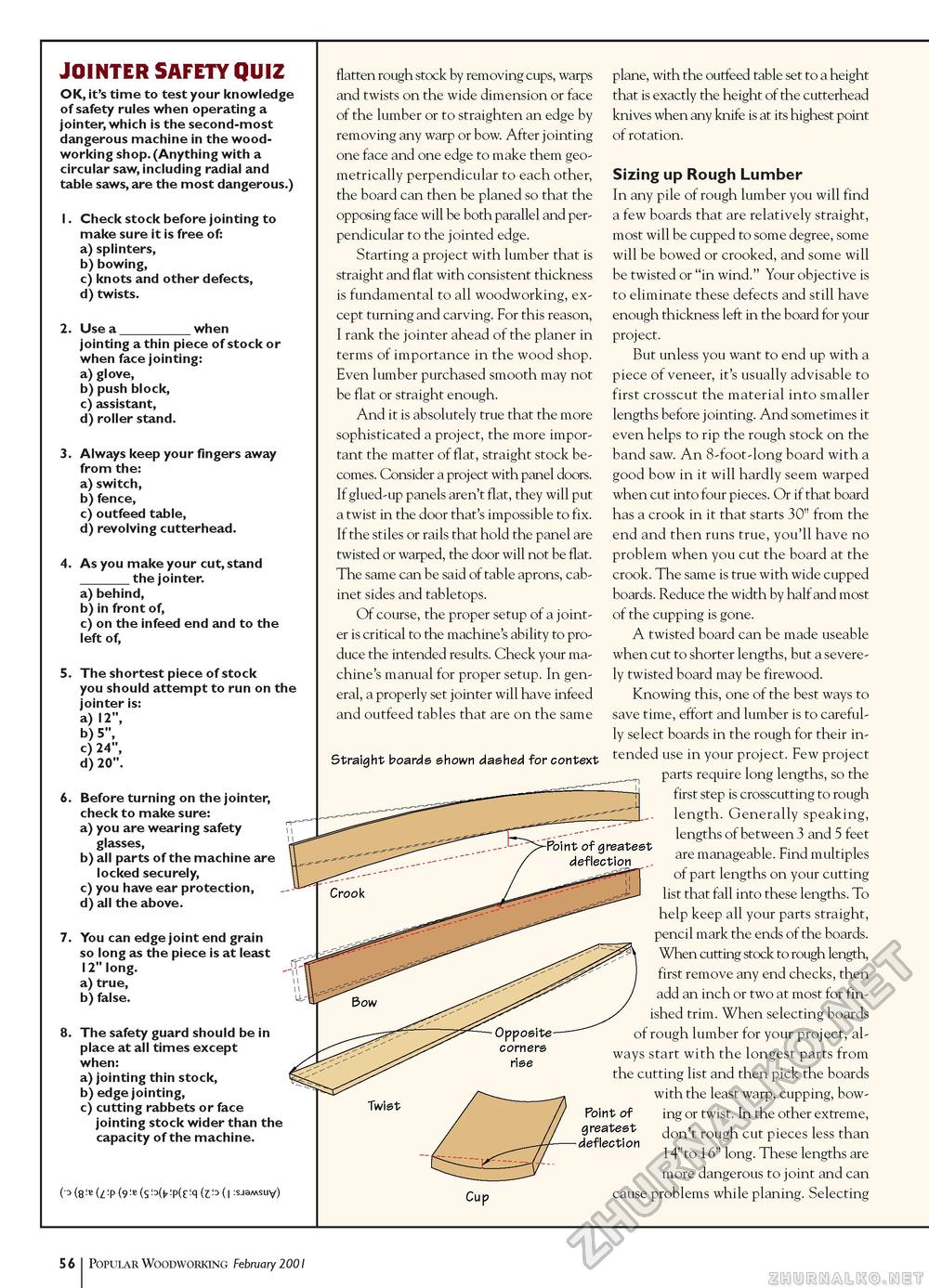

JOINTER SAFETY QUIZ OK, it's time to test your knowledge of safety rules when operating a jointer, which is the second-most dangerous machine in the woodworking shop. (Anything with a circular saw, including radial and table saws, are the most dangerous.) 1. Check stock before jointing to make sure it is free of: a) splinters, b) bowing, c) knots and other defects, d) twists. 2. Use a_when jointing a thin piece of stock or when face jointing: a) glove, b) push block, c) assistant, d) roller stand. 3. Always keep your fingers away from the: a) switch, b) fence, c) outfeed table, d) revolving cutterhead. 4. As you make your cut, stand _the jointer. a) behind, b) in front of, c) on the infeed end and to the left of, 5. The shortest piece of stock you should attempt to run on the jointer is: a) 12", b) 5", c) 24", d) 20". 6. Before turning on the jointer, check to make sure: a) you are wearing safety glasses, b) all parts of the machine are locked securely, c) you have ear protection, d) all the above. 7. You can edge joint end grain so long as the piece is at least 12" long. a) true, b) false. 8. The safety guard should be in place at all times except when: a) jointing thin stock, b) edge jointing, c) cutting rabbets or face jointing stock wider than the capacity of the machine. (•D (8 'S (z'p (9 * (s 'p(£ 'q (Z;3(l :SJ3MSUV) flatten rough stock by removing cups, warps and twists on the wide dimension or face of the lumber or to straighten an edge by removing any warp or bow. After jointing one face and one edge to make them geometrically perpendicular to each other, the board can then be planed so that the opposing face will be both parallel and perpendicular to the jointed edge. Starting a project with lumber that is straight and flat with consistent thickness is fundamental to all woodworking, except turning and carving. For this reason, I rank the jointer ahead of the planer in terms of importance in the wood shop. Even lumber purchased smooth may not be flat or straight enough. And it is absolutely true that the more sophisticated a project, the more important the matter of flat, straight stock becomes. Consider a project with panel doors. If glued-up panels aren't flat, they will put a twist in the door that's impossible to fix. If the stiles or rails that hold the panel are twisted or warped, the door will not be flat. The same can be said of table aprons, cabinet sides and tabletops. Of course, the proper setup of a jointer is critical to the machine's ability to produce the intended results. Check your machine's manual for proper setup. In general, a properly set jointer will have infeed and outfeed tables that are on the same Straight boards shown dashed for context plane, with the outfeed table set to a height that is exactly the height of the cutterhead knives when any knife is at its highest point of rotation. Sizing up Rough Lumber In any pile of rough lumber you will find a few boards that are relatively straight, most will be cupped to some degree, some will be bowed or crooked, and some will be twisted or "in wind." Your objective is to eliminate these defects and still have enough thickness left in the board for your project. But unless you want to end up with a piece of veneer, it's usually advisable to first crosscut the material into smaller lengths before jointing. And sometimes it even helps to rip the rough stock on the band saw. An 8-foot-long board with a good bow in it will hardly seem warped when cut into four pieces. Or if that board has a crook in it that starts 30" from the end and then runs true, you'll have no problem when you cut the board at the crook. The same is true with wide cupped boards. Reduce the width by half and most of the cupping is gone. A twisted board can be made useable when cut to shorter lengths, but a severely twisted board may be firewood. Knowing this, one of the best ways to save time, effort and lumber is to carefully select boards in the rough for their intended use in your project. Few project parts require long lengths, so the first step is crosscutting to rough length. Generally speaking, lengths of between 3 and 5 feet are manageable. Find multiples of part lengths on your cutting list that fall into these lengths. To help keep all your parts straight, pencil mark the ends of the boards. When cutting stock to rough length, first remove any end checks, then add an inch or two at most for finished trim. When selecting boards of rough lumber for your project, always start with the longest parts from the cutting list and then pick the boards with the least warp, cupping, bowing or twist. In the other extreme, don't rough cut pieces less than 14"to 16" long. These lengths are more dangerous to joint and can cause problems while planing. Selecting Point of greatest deflection 56 Popular Woodworking February 2001 |