Popular Woodworking 2002-04 № 127, страница 24

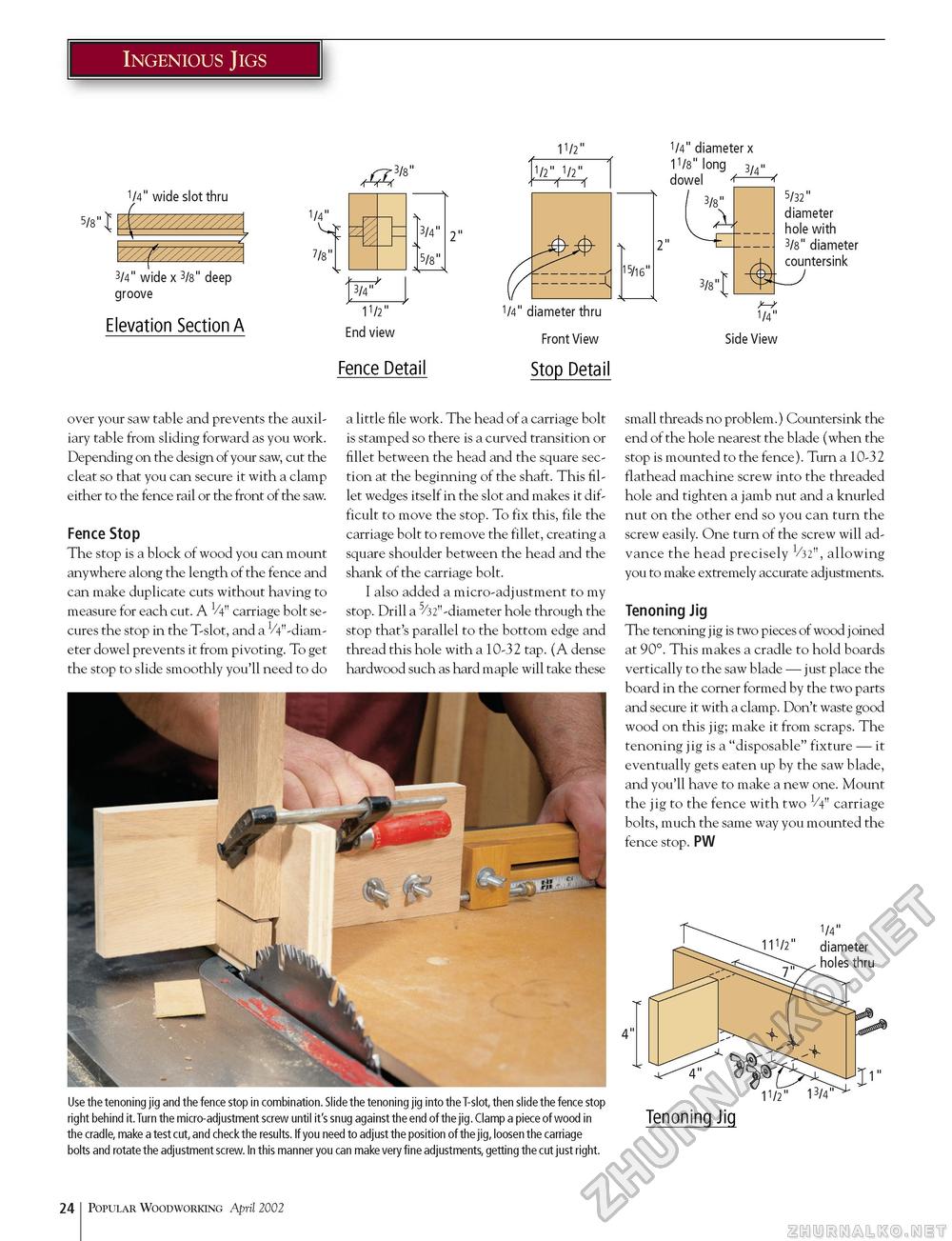

Ingenious Jigs 5/8" ^ 1/4" wide slot thru 3/4" wide x 3/8" deep groove Elevation Section A r73/8" 1/4" 7/8" 3/4" 5/8" 2" 3/4" 11/2" End view Fence Detail 11/2" 1/4" diameter x 11/8" long 3/4" dowel 1/4" diameter thru Front View Stop Detail 5/32 " diameter hole with 3/8" diameter countersink 1/4" Side View over your saw table and prevents the auxiliary table from sliding forward as you work. Depending on the design of your saw, cut the cleat so that you can secure it with a clamp either to the fence rail or the front of the saw. Fence Stop The stop is a block of wood you can mount anywhere along the length of the fence and can make duplicate cuts without having to measure for each cut. A V4" carriage bolt secures the stop in the T-slot, and a ^''-diam-eter dowel prevents it from pivoting. To get the stop to slide smoothly you'll need to do a little file work. The head of a carriage bolt is stamped so there is a curved transition or fillet between the head and the square section at the beginning of the shaft. This fillet wedges itself in the slot and makes it difficult to move the stop. To fix this, file the carriage bolt to remove the fillet, creating a square shoulder between the head and the shank of the carriage bolt. I also added a micro-adjustment to my stop. Drill a 5/32"-diameter hole through the stop that's parallel to the bottom edge and thread this hole with a 10-32 tap. (A dense hardwood such as hard maple will take these Use the tenoning jig and the fence stop in combination. Slide the tenoning jig into the T-slot, then slide the fence stop right behind it.Turn the micro-adjustment screw until it's snug against the end of the jig. Clamp a piece of wood in the cradle, make a test cut, and check the results. If you need to adjust the position of the jig, loosen the carriage bolts and rotate the adjustment screw. In this manner you can make very fine adjustments, getting the cut just right. small threads no problem.) Countersink the end of the hole nearest the blade (when the stop is mounted to the fence). Turn a 10-32 flathead machine screw into the threaded hole and tighten a jamb nut and a knurled nut on the other end so you can turn the screw easily. One turn of the screw will advance the head precisely V32", allowing you to make extremely accurate adjustments. Tenoning Jig The tenoning jig is two pieces of wood joined at 90°. This makes a cradle to hold boards vertically to the saw blade — just place the board in the corner formed by the two parts and secure it with a clamp. Don't waste good wood on this jig; make it from scraps. The tenoning jig is a "disposable" fixture — it eventually gets eaten up by the saw blade, and you'll have to make a new one. Mount the jig to the fence with two V4" carriage bolts, much the same way you mounted the fence stop. PW 24 Popular Woodworking April 2002 |