Popular Woodworking 2002-04 № 127, страница 38

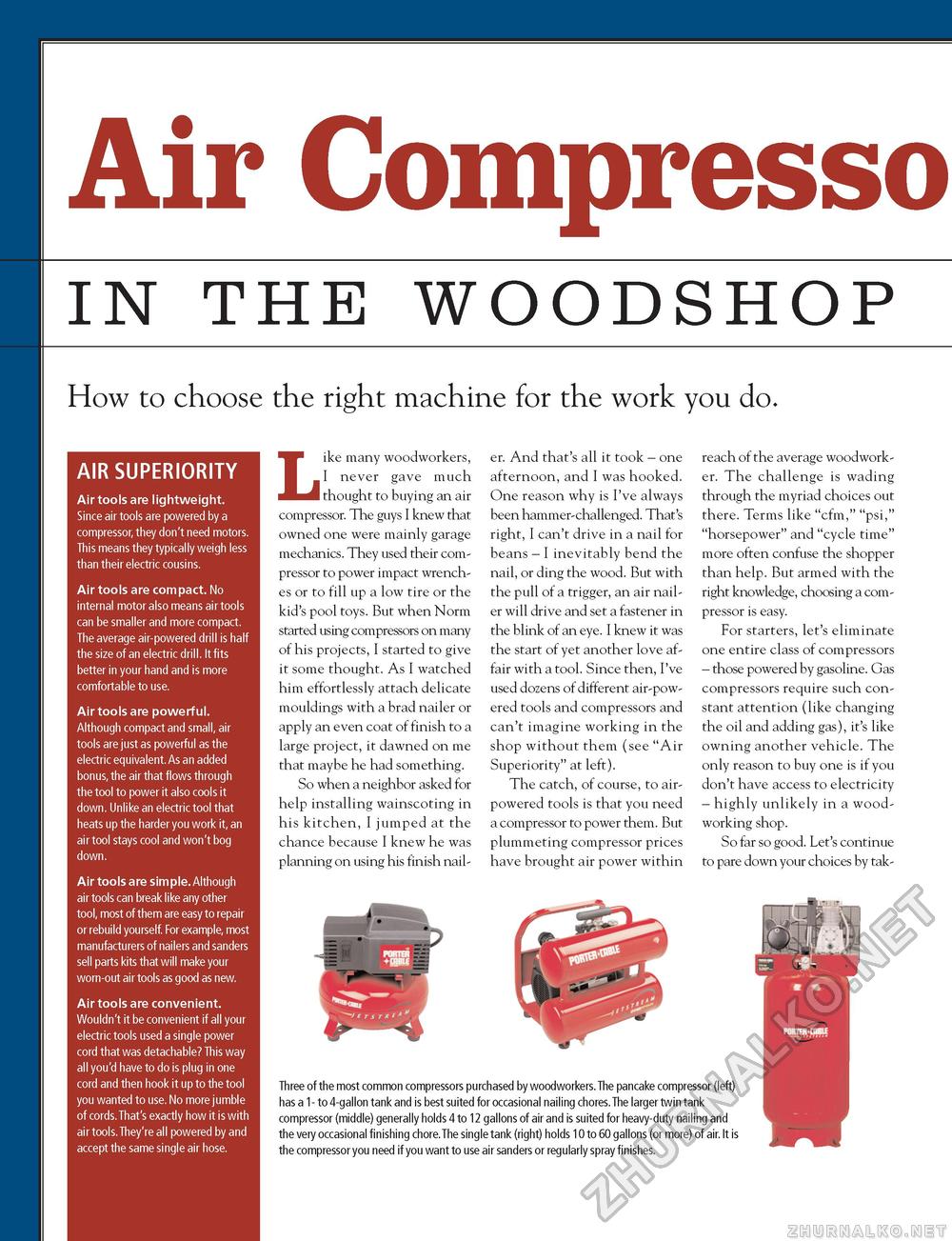

Air CompressoIN THE WOODSHOP How to choose the right machine for the work you do. Like many woodworkers, I never gave much thought to buying an air compressor. The guys I knew that owned one were mainly garage mechanics. They used their compressor to power impact wrenches or to fill up a low tire or the kid's pool toys. But when Norm started using compressors on many of his projects, I started to give it some thought. As I watched him effortlessly attach delicate mouldings with a brad nailer or apply an even coat of finish to a large project, it dawned on me that maybe he had something. So when a neighbor asked for help installing wainscoting in his kitchen, I jumped at the chance because I knew he was planning on using his finish nail- er. And that's all it took - one afternoon, and I was hooked. One reason why is I've always been hammer-challenged. That's right, I can't drive in a nail for beans - I inevitably bend the nail, or ding the wood. But with the pull of a trigger, an air nailer will drive and set a fastener in the blink of an eye. I knew it was the start of yet another love affair with a tool. Since then, I've used dozens of different air-powered tools and compressors and can't imagine working in the shop without them (see "Air Superiority" at left). The catch, of course, to air-powered tools is that you need a compressor to power them. But plummeting compressor prices have brought air power within reach of the average woodworker. The challenge is wading through the myriad choices out there. Terms like "cfm," "psi," "horsepower" and "cycle time" more often confuse the shopper than help. But armed with the right knowledge, choosing a compressor is easy. For starters, let's eliminate one entire class of compressors - those powered by gasoline. Gas compressors require such constant attention (like changing the oil and adding gas), it's like owning another vehicle. The only reason to buy one is if you don't have access to electricity - highly unlikely in a woodworking shop. So far so good. Let's continue to pare down your choices by tak- Three of the most common compressors purchased by woodworkers. The pancake compressor (left) has a 1- to 4-gallon tank and is best suited for occasional nailing chores.The larger twin tank compressor (middle) generally holds 4 to 12 gallons of air and is suited for heavy-duty nailing and the very occasional finishing chore.The single tank (right) holds 10 to 60 gallons (or more) of air. It is the compressor you need if you want to use air sanders or regularly spray finishes. AIR SUPERIORITY Air tools are lightweight. Since air tools are powered by a compressor, they don't need motors. This means they typically weigh less than their electric cousins. Air tools are compact. No internal motor also means air tools can be smaller and more compact. The average air-powered drill is half the size of an electric drill. It fits better in your hand and is more comfortable to use. Air tools are powerful. Although compact and small, air tools are just as powerful as the electric equivalent. As an added bonus, the air that flows through the tool to power it also cools it down. Unlike an electric tool that heats up the harder you work it, an air tool stays cool and won't bog down. Air tools are simple. Although air tools can break like any other tool, most of them are easy to repair or rebuild yourself. For example, most manufacturers of nailers and sanders sell parts kits that will make your worn-out air tools as good as new. Air tools are convenient. Wouldn't it be convenient if all your electric tools used a single power cord that was detachable? This way all you'd have to do is plug in one cord and then hook it up to the tool you wanted to use. No more jumble of cords. That's exactly how it is with air tools.They're all powered by and accept the same single air hose. |