Popular Woodworking 2002-04 № 127, страница 37

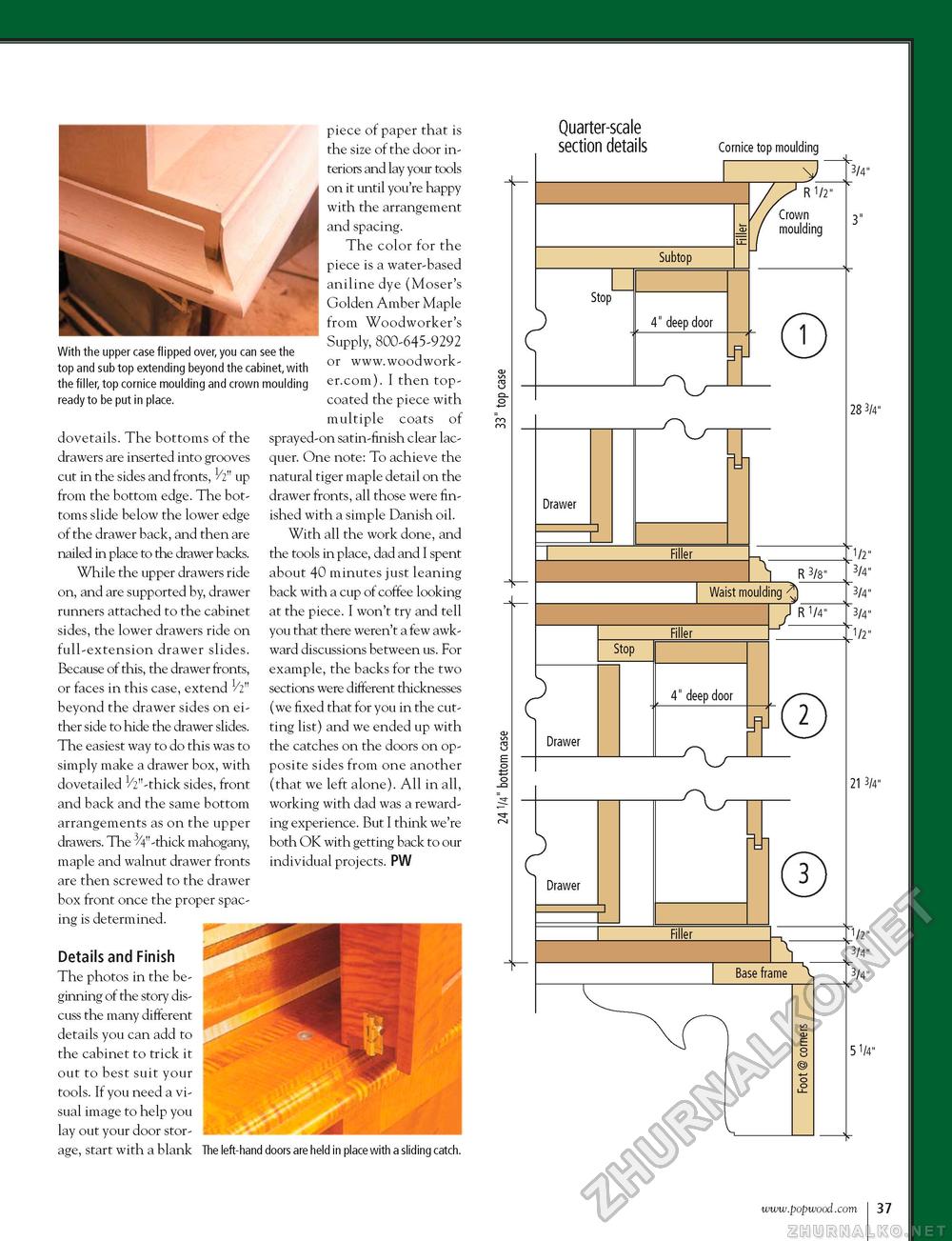

With the upper case flipped over, you can see the top and sub top extending beyond the cabinet, with the filler, top cornice moulding and crown moulding ready to be put in place. dovetails. The bottoms of the drawers are inserted into grooves cut in the sides and fronts, 1/2n up from the bottom edge. The bottoms slide below the lower edge of the drawer back, and then are nailed in place to the drawer backs. While the upper drawers ride on, and are supported by, drawer runners attached to the cabinet sides, the lower drawers ride on full-extension drawer slides. Because of this, the drawer fronts, or faces in this case, extend V2'1 beyond the drawer sides on either side to hide the drawer slides. The easiest way to do this was to simply make a drawer box, with dovetailed 1/2"-thick sides, front and back and the same bottom arrangements as on the upper drawers. The ^V'-thick mahogany, maple and walnut drawer fronts are then screwed to the drawer box front once the proper spacing is determined. Details and Finish The photos in the beginning of the story discuss the many different details you can add to the cabinet to trick it out to best suit your tools. If you need a visual image to help you lay out your door storage, start with a blank piece of paper that is the size of the door interiors and lay your tools on it until you're happy with the arrangement and spacing. The color for the piece is a water-based aniline dye (Moser's Golden Amber Maple from Woodworker's Supply, 800-645-9292 or www. woodwork -er.com). I then top-coated the piece with multiple coats of sprayed-on satin-finish clear lacquer. One note: To achieve the natural tiger maple detail on the drawer fronts, all those were finished with a simple Danish oil. With all the work done, and the tools in place, dad and I spent about 40 minutes just leaning back with a cup of coffee looking at the piece. I won't try and tell you that there weren't a few awkward discussions between us. For example, the backs for the two sections were different thicknesses (we fixed that for you in the cutting list) and we ended up with the catches on the doors on opposite sides from one another (that we left alone). All in all, working with dad was a rewarding experience. But I think we're both OK with getting back to our individual projects. PW Quarter-scale section details Cornice top moulding Subtop Stop 4" deep door m R V/2" Crown moulding Drawer hJ Filler R 3/8" Drawer Filler Waist moulding ^JrW Stop 4" deep door Lfl ( 2 Drawer hJ 3 "1/2 3/4 3/4 3/4 1/2

3/4" 3" 28 3/4" 21 3/4" 5 V/4" The left-hand doors are held in place with a sliding catch. 37 |

|||||||||